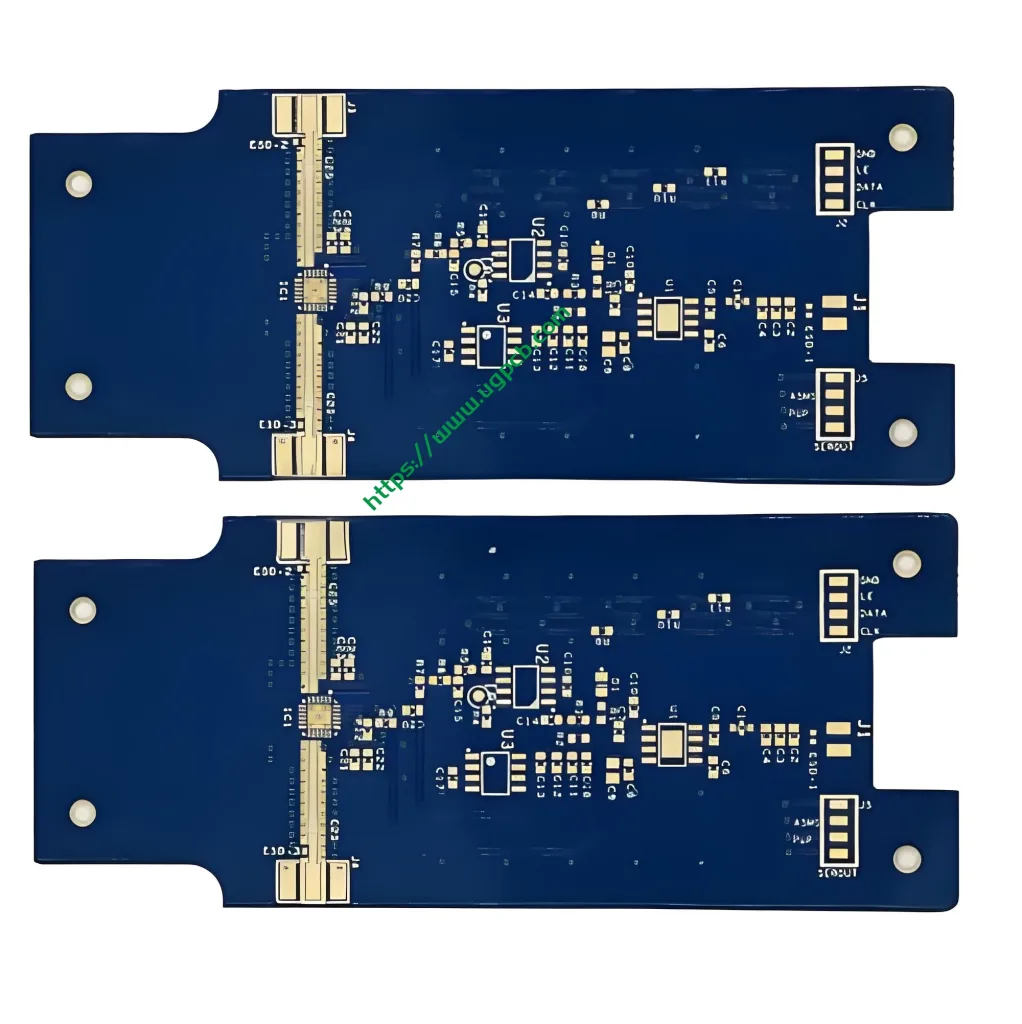

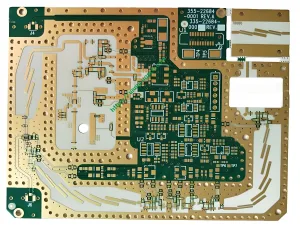

Aperçu du PCB en téflon

PCB en téflon, connu pour ses performances exceptionnelles dans les applications à haute fréquence, est un type de carte de circuit imprimé (PCB) qui utilise un matériau stratifié en téflon. Ce matériau est choisi pour ses propriétés diélectriques supérieures, Le faire idéal pour les appareils électroniques micro-ondes et à haute fréquence. La qualité des PCB en téflon adhère généralement aux normes de classe II ou de classe III de l'IPC6012, Assurer des performances fiables et cohérentes.

Définition et spécifications clés

Un PCB en téflon est défini par son utilisation du téflon comme matériau diélectrique, qui offre une constante diélectrique allant de 2.0 à 3.5. Ces planches peuvent être fabriquées avec un nombre de couches allant de 2 à 34 couches, offrant une flexibilité pour diverses complexités dans la conception de circuits. L'épaisseur des PCB en téflon peut varier de 0,1 mm à 12 mm, répondant à différents besoins d'application. L'épaisseur du cuivre commence généralement par une base de 0,5 oz et peut être terminée jusqu'à 1 oz, Assurer une conductivité adéquate pour les signaux à haute fréquence.

Considérations de conception

Lors de la conception de PCB en téflon, Plusieurs facteurs clés doivent être pris en compte:

- Constante diélectrique (Ne sait pas) et facteur de dissipation (Df): Les matériaux doivent avoir des valeurs DK et DF précises pour assurer l'intégrité du signal et minimiser la perte à des fréquences élevées.

- Compte et épaisseur des calques: En fonction de la complexité du circuit, Le nombre de couches et d'épaisseur globale peuvent être ajustés dans les plages spécifiées.

- Épaisseur du cuivre: L'épaisseur adéquate du cuivre est cruciale pour maintenir une faible impédance et réduire la perte de signal.

- Technologie de surface: Des options comme l'or à immersion et l'isig (Immersion Silver) sont disponibles pour les finitions de surface, chacun offrant des avantages différents en termes de conductivité et de fiabilité.

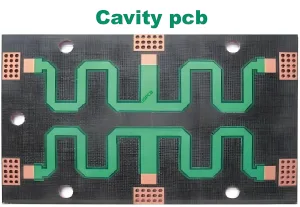

Principe de fonctionnement

Les PCB en téflon fonctionnent en fonction du principe de l'impédance contrôlée et de la perte de signal minimale, qui est essentiel pour les applications à haute fréquence. La faible constante diélectrique du matériau du téflon aide à maintenir l'intégrité du signal en réduisant les retards de phase et l'atténuation. Cela rend les PCB en téflon particulièrement adaptés au micro-ondes et à RF (Radiofréquence) applications où la pureté du signal est critique.

Applications

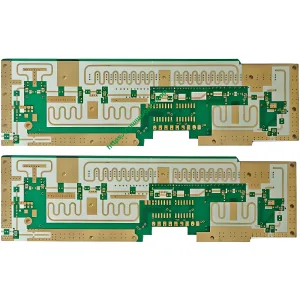

L'application principale des PCB en téflon se trouve dans le domaine des micro-ondes et de l'électronique à haute fréquence. Ils sont utilisés dans des appareils tels que les systèmes radar, communications par satellite, et d'autres composants RF où les performances et la fiabilité élevées sont primordiales. La capacité de gérer les hautes fréquences avec une perte minimale fait des PCB en téflon un excellent choix pour ces applications exigeantes.

Classification

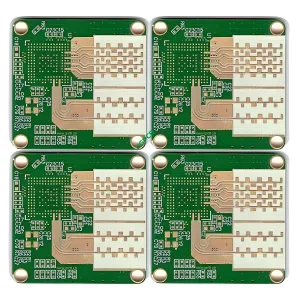

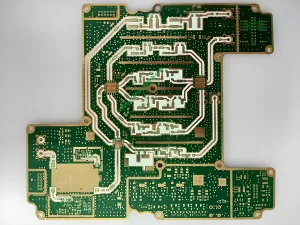

Les PCB en téflon peuvent être classés en fonction de leur nombre de couches, épaisseur, et applications spécifiques. Les classifications courantes incluent:

- Planches à un côté et double face: Pour des applications plus simples avec moins de couches.

- Panneaux multicouches: Pour des circuits plus complexes nécessitant plusieurs couches d'interconnexions.

- Boches spécifiques à haute fréquence: Conçu spécifiquement pour les applications micro-ondes et RF, Souvent avec des exigences strictes sur les propriétés des matériaux et la précision de fabrication.

Propriétés des matériaux

Les propriétés uniques du téflon en font un matériau idéal pour les PCB haute fréquence:

- Faible constante diélectrique: Aide à réduire le délai et la perte du signal.

- Performances stables à travers les plages de température: Assure des performances cohérentes dans des conditions environnementales variables.

- Haute résistance à l'absorption d'humidité: Empêche la dégradation de la qualité du signal en raison de la pénétration d'humidité.

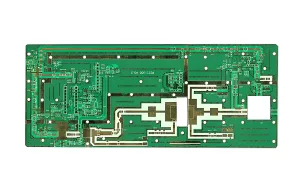

Processus de production

La production de PCB en téflon implique plusieurs étapes:

- Sélection des matériaux: Choisir le matériau en téflon approprié en fonction des valeurs DK et DF requises.

- Conception de circuit: Création de la disposition du circuit avec des considérations pour les performances à haute fréquence.

- Gravure: Suppression du cuivre inutile pour créer le modèle de circuit souhaité.

- Laminage: Liaison plusieurs couches ensemble sous haute pression et température.

- Finition des surfaces: Appliquer la technologie de surface choisie, comme l'or immersion ou l'isig.

- Tests et contrôle qualité: S'assurer que le produit final répond à toutes les spécifications et normes.

Utiliser des scénarios

Les PCB en téflon sont utilisés dans des scénarios où les performances à haute fréquence sont essentielles, tel que:

- Antennes micro-ondes: Pour une transmission et une réception de signaux efficaces.

- Communications par satellite: Assurer un transfert de données fiable entre la Terre et l'espace.

- Radar: Fournir des capacités de traitement des signaux précises et stables.

En conclusion, Les PCB en téflon sont des cartes de circuits imprimées conçues pour des applications à haute fréquence, offrant d'excellentes propriétés diélectriques et intégrité du signal. Leur conception, matériels, et les processus de production sont adaptés pour répondre aux exigences strictes des technologies micro-ondes et RF.

LOGO UGPCB

LOGO UGPCB