S1150GH features

– Lead-free compatibility and excellent ion migration resistance

– Faible coefficient de dilatation thermique sur l'axe Z

– Halogen-free PCB, antimony-free, red phosphorus free, and no other highly toxic and residual toxic components during waste combustion

– Applicable to high-end HDI performance processing requirements

S1150GH application field

– Electronique grand public

– Smartphones, tablets, ordinateurs portables

– LED, Game device

S1150GH PCB Material

Halogen-free PCB Material Shengyi S1150GH

Halogen-free PCB material of Shengyi S1150G.

PCB material for halogen-free high reliability multilayer board: S1150GH+prepreg: S1150GHB PCB manufacturing precautions

1. S1150GH/S1150GHB storage conditions

1.1 S1150GH/S1150GHB copper clad plate

1.1.1 Méthode de stockage

Put it on the platform or suitable rack in the original packaging form to avoid heavy pressure and prevent deformation of the plate caused by improper storage.

1.1.2 Environnement de stockage

Les plaques doivent être stockées dans un endroit aéré, environnement sec et à température ambiante pour éviter la lumière directe du soleil, rain and corrosive gas erosion (the storage environment directly affects the plate quality). Double panels should be stored in a suitable environment for two years, and single panels should be stored in a suitable environment for one year. Ses performances internes peuvent répondre aux exigences de la norme IPC4101.

1.1.3 Opération

Wear cleaning gloves to handle the plate carefully. Collision, glissement, etc.. endommagera la feuille de cuivre, et l'opération à main nue polluera la surface de la feuille de cuivre. Ces défauts peuvent avoir un impact négatif sur l'utilisation de la plaque.

1.2 Feuille semi-durcissante

1.2.1 Méthode de stockage

Store horizontally in the original packaging form to avoid heavy pressure and damage of the semi curing sheet caused by improper storage. The remaining roll shaped semi curing sheet after cutting shall be sealed and packed with fresh film and put back on the bracket in the original packaging.

1.2.2 Environnement de stockage

Le préimprégné doit être stocké dans un emballage scellé dans un environnement exempt de lumière ultraviolette.. Les conditions spécifiques de stockage et la durée de stockage sont les suivantes

Condition 1: température<23 ℃, humidité relative<50%, période de stockage de 3 mois,

Condition 2: température<5 ℃, période de stockage de 6 mois,

The relative humidity has a great influence on the quality of the prepreg, and the corresponding dehumidification treatment should be carried out in humid weather. It is recommended to use the prepreg within 3 days after unpacking.

1.2.3 Coupe

It is better for professionals to wear clean gloves for cutting to prevent the surface of the prepreg from being polluted. L'opération doit être effectuée avec soin pour éviter que le préimprégné ne se froisse ou ne se froisse.. When PP is cut, the worktable should be cleaned first to avoid cross contamination of different types of PP resin powder.

1.2.4 Précautions

Lorsque le préimprégné est sorti de la chambre froide, il doit passer par le processus de récupération de température avant d'ouvrir l'emballage. Le temps de récupération de la température est supérieur à 8 heures (en fonction des conditions spécifiques de stockage). The package can be opened after the same temperature as the ambient temperature. The prepreg that has been opened into sheets must be stored in Condition 1 ou Condition 2 et épuisé dès que possible. After more than 3 jours, il doit être revérifié et utilisé après qualification de ses indicateurs. After the roll shaped prepreg is opened, the remaining roll shaped mantissa shall be used, It is required to carry out sealed packaging of the original packaging degree and store it in Condition 1 ou Condition 2. S'il existe un plan d'inspection CIQ, the prepreg shall be tested as soon as possible after receipt (pas plus que 5 jours) selon la norme IPC-4101. If the prepreg is dehumidified before use, it is recommended to set the conditions for the dehumidification cabinet: température<23 ℃, relative humidity about 40%, and the upper limit of fluctuation shall not exceed 50%.

2. S1150GH/S1150GHB PCB processing suggestions

2.1 Coupe

Il est recommandé d'utiliser une machine à scier pour couper, suivi d'une cisaille. Note that cutting with roller knife may cause plate edge delamination, so as to avoid plate edge delamination due to tool wear and improper clearance.

2.2 Cuisson de la plaque à noyau

According to the actual use situation, the core plate can be baked. If the core plate is baked after opening, it is recommended that the core plate be baked after a high-pressure water wash after opening to avoid the introduction of resin powder produced during the shearing process to the plate surface, ce qui peut entraîner une mauvaise gravure. It is recommended that the core plate be opened and baked at 150 ℃/2~4h. Notez que la plaque ne peut pas entrer directement en contact avec la source de chaleur.

2.3 Browning of inner layer

S1150GH scheme is suitable for browning process.

2.4 Empilage

Le processus d'empilage doit garantir que la séquence d'empilement des feuilles de liaison est cohérente, and the overturning action shall be avoided during the stacking process to reduce the problems such as warping, deformation and folding caused thereby.

The time from browning of core plate to pressing plate shall be controlled within 12 heures. When the buffer material may have moisture absorption risk, it is recommended to dry it.

Due to the material characteristics, it is easy to carry static electricity. When stacking, pay special attention to the adsorption of foreign matters on PP.

In order to ensure good alignment effect of expansion and contraction during plate arrangement, it is recommended to use rivet riveting for fixation. If fusion is required, it is recommended to use electromagnetic heat fusion. En même temps, the best fusion effect parameters should be evaluated in detail. For other fusion methods, the PCB’s own conditions should be carefully evaluated for fusion effect to avoid layer deviation caused by poor fusion.

2.5 Laminage

It is recommended to select the press plate with good vacuum pumping performance and vacuum valve sealing to avoid the entry of external moisture.

The recommended heating rate is 1.5~2.5 ℃/min (the material temperature is within the range of 80~140 ℃).

It is recommended that the laminating pressure be 350-430psi (presse hydraulique). The specific high pressure should be adjusted according to the structural characteristics of the plate (le nombre de préimprégnés et la taille de la zone de remplissage de colle). It is recommended to turn to high pressure at 80-100 ℃.

Curing conditions: température 180 ℃, time more than 60min.

Cooling rate < 2 ℃/min.

The material temperature of hot pressing is less than 150 ℃.

If copper foil heat conduction press is used, Shengyi Company shall be informed in advance.

Si des panneaux isolants ou des panneaux simples sont utilisés dans des panneaux multicouches, les panneaux isolants ou les panneaux individuels doivent être rendus rugueux avant d'être utilisés pour éviter une force de liaison insuffisante causée par des panneaux isolants trop lisses, ou les panneaux double face peuvent être gravés en panneaux simples ou en panneaux isolants pour la production.

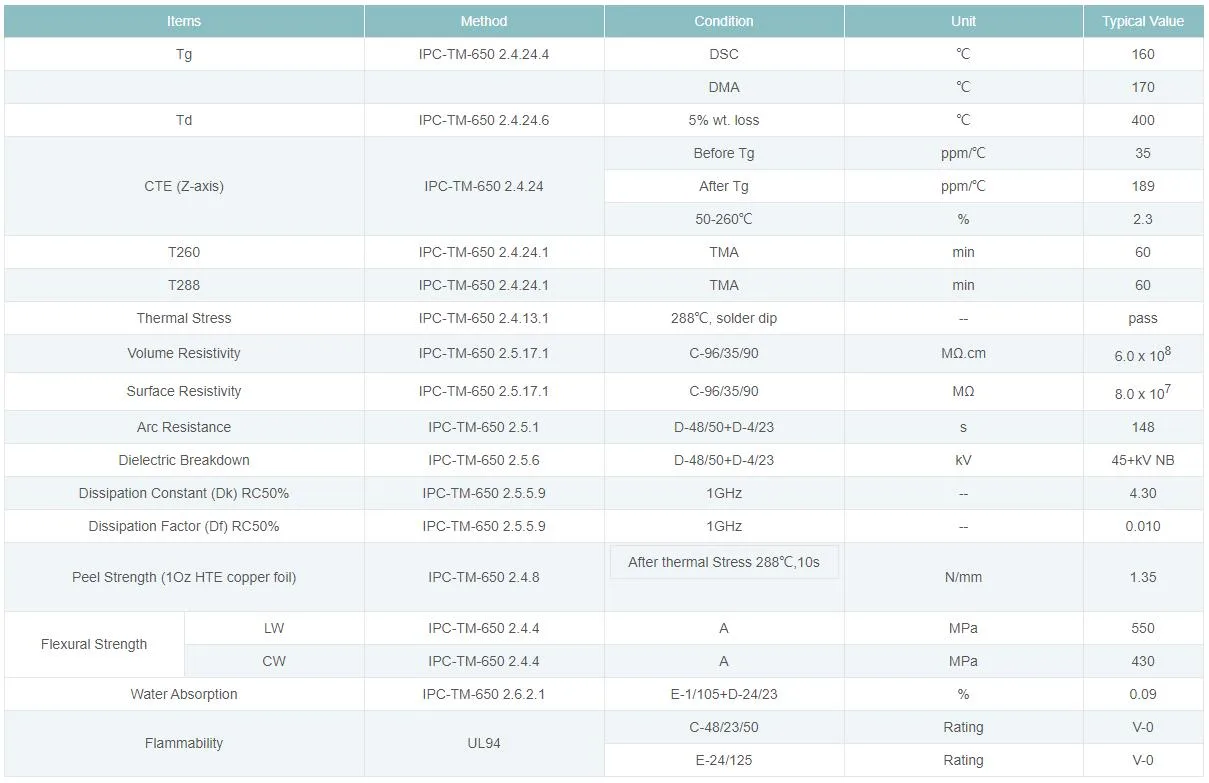

Shengyi S1150G Halogen-Free PCB material Specifications Table

2.6 Forage

It is better to use a new drill.

The stack thickness is recommended to be no more than 2 pieces/stack (calculated as per the plate thickness of 1.6mm/block).

It is recommended to limit the drilling hole to 1000-2000 holes.

The feed rate for drilling shall be 15-20% lower than that for processing ordinary FR-4 materials.

2.7 Drying plate after drilling

It is suggested that the drying conditions after drilling should be 170-180 ℃/3h. Note that the plates should not be in direct contact with the heat source.

Baking before resin plug hole after back drilling: 170-180 ℃/2-3h.

2.8 Dirt removal

It is suggested that the specific parameters should be set according to the actual PCB structure (board thickness, aperture size), and all kinds of structural boards should be fully evaluated in detail to determine the best matching glue removal conditions and parameters. The glue removal effect should refer to the fact that there is no resin residue at the copper junction of the inner layer. The horizontal Desmear or vertical Desmear is recommended. The specific glue removal conditions are related to the equipment, liquid medicine model, board thickness or hole area. Under the premise of full load, the thicker the board is recommended, The longer the degumming time is.

2.9 Solder resistance ink

It is recommended that the drying plate before green oil: 130 ℃/2-4h,

Lorsque vous utilisez la grille pour la cuisson, si la plaque est écrasée ou déformée lors de l'insertion de la grille, une déformation se produira après la cuisson. It is not recommended to back wash the solder resist ink, which may cause white spots.

2.10 Pulvérisation d'étain

It is suitable for lead-free tin spraying process. For the structure of thick copper and large copper surface on the outer layer (or thick copper plating), the temperature is high during lead-free tin spraying, resulting in excessive thermal stress, which is prone to white spots between large copper surfaces, copper skin warping and other problems. The improvement measures are as follows:

1. Try to reduce the tin spraying temperature, shorten the tin spraying time, and reduce the thermal stress generated during tin spraying,

2. Before tin spraying, pre bake the plate under the condition of 140-150 ℃/2h, and spray tin immediately to remove the moisture accumulated on the plate surface, which can reduce the probability of white spots,

3. Avoid too large tin spraying surface, or increase the thickness of green oil appropriately, which can well cushion the thermal stress generated during tin spraying,

4. The large copper surface structure is designed as a grid structure.

2.11 Traitement du profil

It is recommended to use a milling machine for processing and reduce the traveling speed appropriately. It is not recommended to use a beer plate for processing.

2.12 Conditionnement

It is recommended to bake the plate before packaging under the condition of 120 ℃/4-6h to avoid heat resistance degradation caused by moisture. Aluminum foil vacuum packaging is recommended.

3. S1150GH/S1150GHB welding

3.1 Validité de l'emballage

It is recommended to use vacuum aluminum foil bags for packaging, and the recommended period of validity is 3 mois. Il est préférable de cuire les composants à 120 ℃ for 4~6h before assembly.

3.2 S1150GH/S1150GHB reflow welding parameters

Suitable for conventional lead-free reflow soldering process.

La température de soudage est de 350 ~ 380 ℃ (using temperature controlled soldering iron),

Temps de soudage d'un seul point de soudage: dans 3 secondes.

LOGO UGPCB

LOGO UGPCB