Introduction to Rogers PCB Products

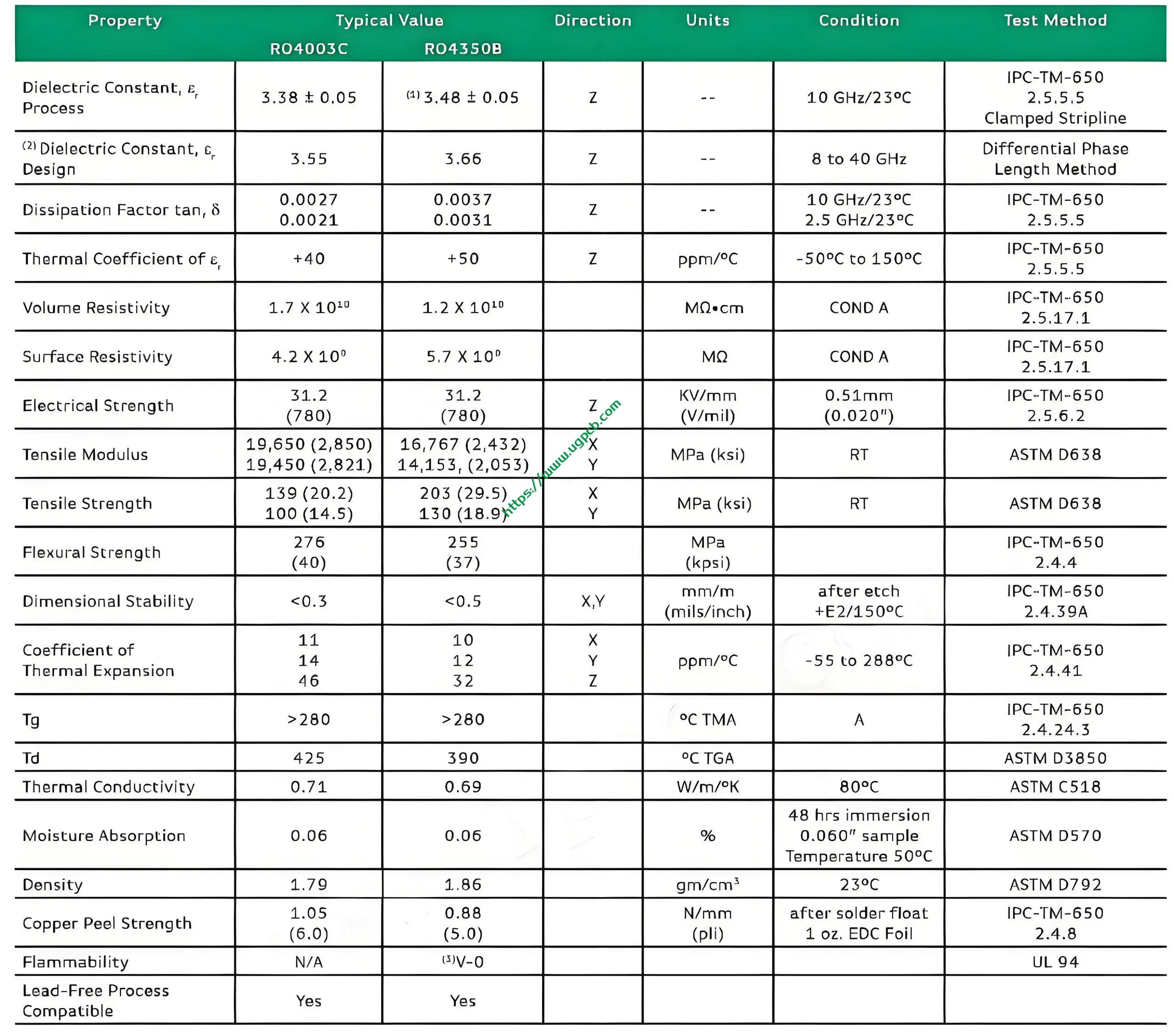

Rogers 4350 and RO4003C, produced by Rogers PCB, are highly mature products known for their stable dielectric constants. The manufacturing process values stand at 3.48 ± 0.05 et 3.38 ± 0.05, respectivement, with design values being 3.66 et 3.55. Due to the variation in dielectric constant characteristics with frequency, designing and simulating according to actual application frequencies is crucial.

Rogers RO4003C and RO4350B Data Sheets

Rogers RO4003C and RO4350B PCB Data Sheets

These data sheets provide comprehensive details on the specifications and performance of Rogers RO4003C and RO4350B materials, essential for accurate design and application.

Rogers RO4003C PCB Data Sheet

The Rogers RO4003C data sheet highlights its unique properties, including its electrical performance akin to PTFE/woven glass and manufacturability similar to epoxy/glass. It offers tight control over dielectric constant and low loss, making it a cost-effective alternative to conventional microwave laminates without requiring special through-hole treatments or handling procedures.

Rogers RO4350B PCB Data Sheet

The Rogers RO4350B data sheet details its patented hydrocarbon resin system reinforced with ceramic filler and woven glass cloth. It closely mimics the electrical properties of PTFE/woven glass while offering machinability similar to epoxy resin/glass cloth. This material provides strictly controlled permittivity and loss at a fraction of the price of traditional microwave materials, eliminating the need for special pretreatments or operational procedures.

Material Characteristics and Applications

Rogers RO4003C Material Characteristics

RO4003C materials are non-brominated and do not have a UL 94V-0 rating. For applications requiring this flame rating, RO4835 and RO4350B laminates are suitable alternatives.

Rogers RO4350B Material Characteristics

RO4350B has passed the UL 94V-0 fire rating, making it suitable for active equipment and high voltage RF designs. Its typical applications include high reliability aerospace and defense, cellular base station antennas, amplificateurs de puissance, microwave point-to-point connections, radar et capteurs automobiles, radio frequency identification (RFID) tags, and LNB for live satellite.

Differences Between Rogers 4350 and RO4003C

Performance Comparison

The performance of RO4350B and RO4003C is essentially similar. The nominal value of the dielectric constant for RO4003C is 3.38 ± 0.5, with a recommended circuit design value of 3.55 and a loss factor/tanδ of 0.0027/0.0021. For RO4350B, the dielectric constant’s manufacturing nominal value is 3.48 ± 0.05, with a recommended circuit design value of 3.66 and a loss factor/tanδ of 0.0037/0.0031.

Environmental Considerations

The main difference between RO4350B and RO4003C lies in their environmental impact. RO4003C is halogen-free, making it more environmentally friendly compared to RO4350B.

Conclusion

En résumé, Rogers 4350 and RO4003C are both reliable choices for specific applications, with slight variations in their performance parameters and environmental impact. The choice between the two will depend on the specific requirements of the application, including environmental considerations and the need for specific certifications like the UL 94V-0 flame rating.

LOGO UGPCB

LOGO UGPCB