Matériaux RO4003C non bromés

Les matériaux Rogers RO4003C ne sont pas bromés et ne sont pas ul 94 V-0 classé. Pour les applications ou les conceptions nécessitant un ul 94 V-0 cote de flamme, Les stratifiés RO4835 et RO4350B répondent à cette exigence.

Verre tissé propriétaire renforcé

Hydrocarbure / céramique

Les matériaux Rogers RO4003C sont des hydrocarbures / céramiques renforcés en verre tissé propriétaire avec les performances électriques de PTFE / Verre tissée et la fabrication d'époxy / verre. Offert dans diverses configurations, RO4003C utilise les deux 1080 et 1674 Styles de tissu en verre avec toutes les configurations rencontrant la même spécification de performance électrique stratifiée.

Contrôle diélectrique rentable et faible perte

RO4003C fournit un contrôle étroit sur la constante diélectrique et une faible perte tout en utilisant la même méthode de traitement que l'époxy / verre standard mais à une fraction du coût des stratifiés micro-ondes conventionnels. Contrairement aux matériaux micro-ondes basés sur PTFE, Aucun traitement spécial ou procédure de manutention n'est requis.

Matériaux de circuit à haute fréquence

La série Rogers Ro4000 de matériaux de circuit à haute fréquence est un hydrocarbure renforcé en verre et de la céramique (PCB non téflon) stratifiés conçus pour les applications commerciales de masse sensibles aux performances. Rogers RO4000 PCB est conçu pour offrir d'excellentes performances à haute fréquence et une fabrication de circuits à faible coût. Le résultat est un matériau à faible perte qui peut être fabriqué en utilisant l'époxy standard / verre (FR4) processus.

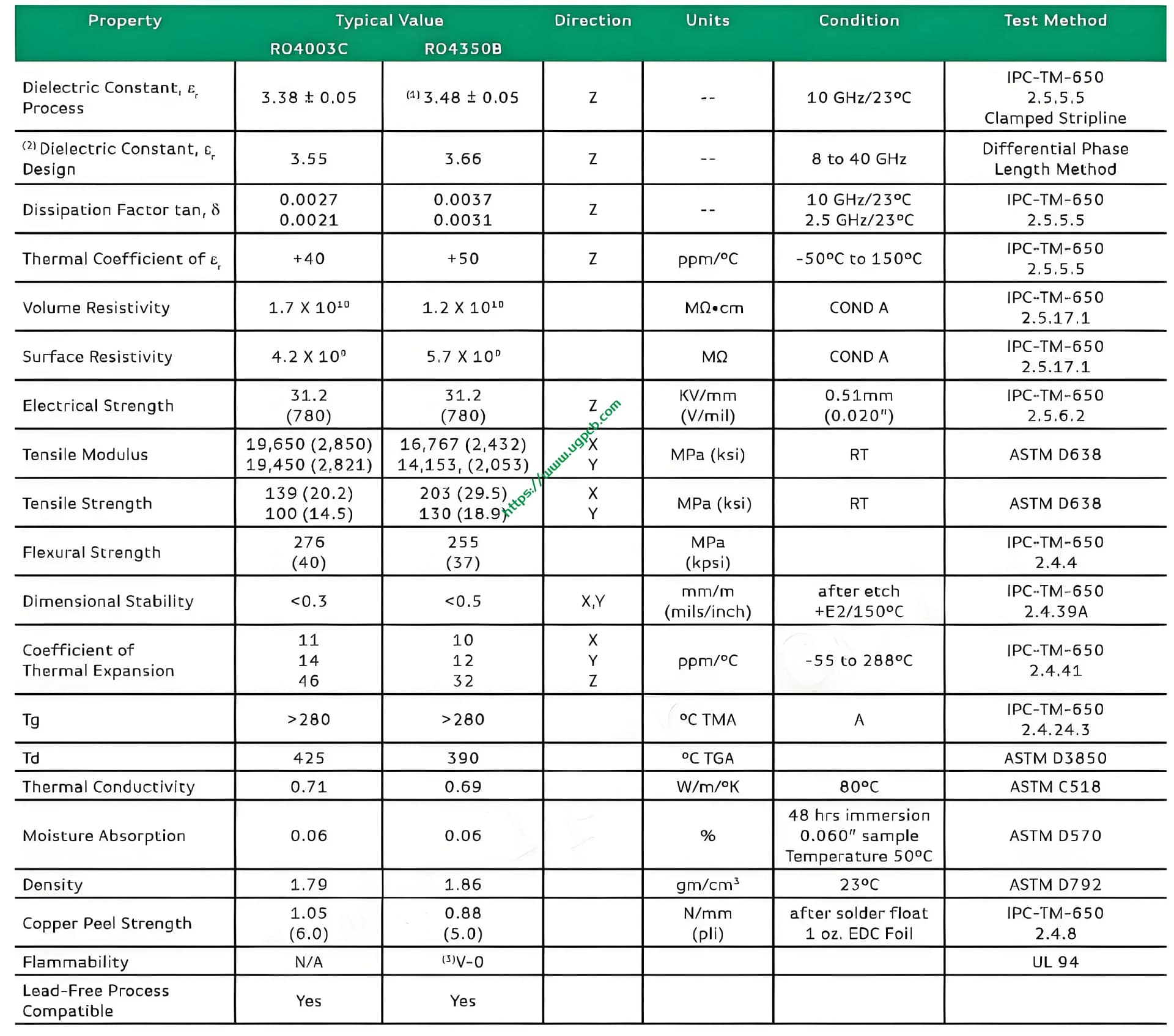

Spécification du matériau Rogers RO4003C

Les fonctionnalités Rogers RO4003C incluent:

- Dk de 3.38 +/- 0.05

- Facteur de dissipation de 0.0027 à 10 GHz

- COEFFICANT DE L'AXIS A 46 ppm/°C

Avantages de Rogers RO4003C

- Idéal pour la carte multicouche (MLB) construction

- Processus comme FR-4 à un coût de fabrication inférieur

- Conçu pour les performances sensibles, Applications à volume élevé

- À un prix compétitif

Applications typiques de Rogers RO4003C

Aérospatiale et défense à haute fiabilité, Une large gamme d'applications micro-ondes / RF typiques et non traditionnelles.

LOGO UGPCB

LOGO UGPCB