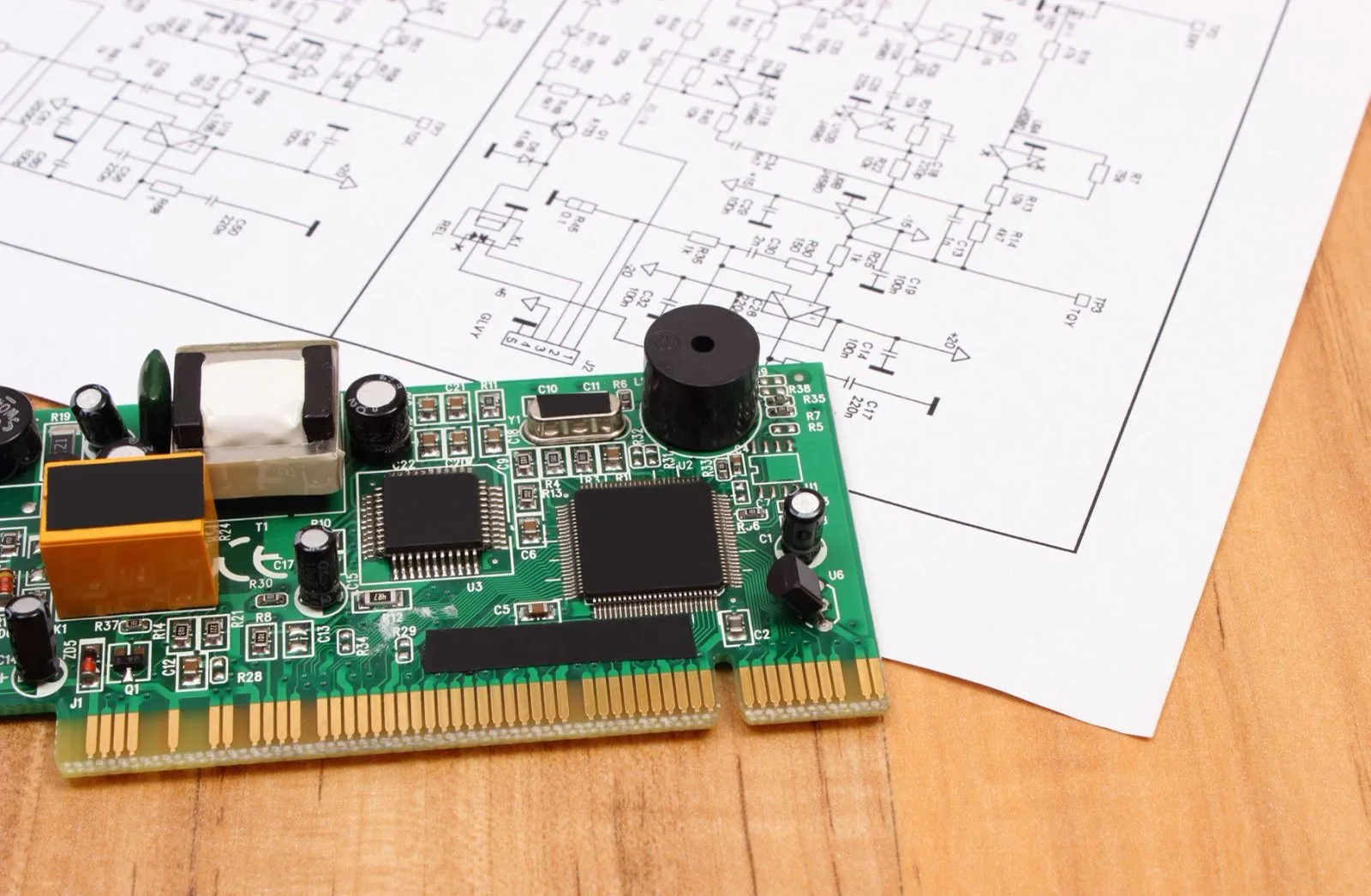

Progettazione PCB

Vantaggi fondamentali dei nostri servizi di progettazione PCB

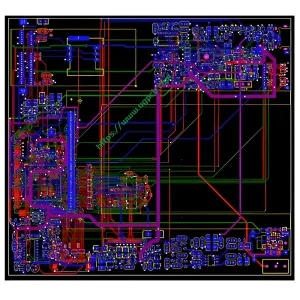

Come provider di servizi PCB unico, Abbiamo oltre un decennio di competenze nella progettazione di PCB, Supportato da un team di sviluppo hardware altamente qualificato e funzionalità di progettazione end-to-end complete. Sfruttare gli strumenti software EDA avanzati (come Cadence Allegro e Mentor Xpedition) e piattaforme di verifica della simulazione, Siamo specializzati in alta complessità, Progetti di PCB ad alta affidabilità per le industrie tra cui l'elettronica di consumo, controllo industriale, elettronica automobilistica, e dispositivi medici. Adepando a rigorosi standard IPC e DFM (Progettazione per la produzione) linee guida, Garantiamo che i nostri progetti ottengano sia l'ottimizzazione delle prestazioni che la fattibilità della produzione di massa.

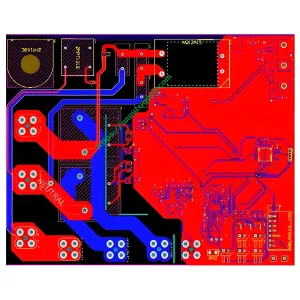

Capacità tecniche e direzioni di innovazione

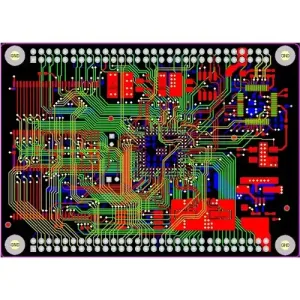

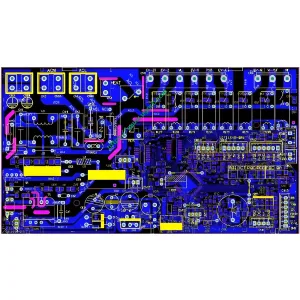

Interconnessione ad alta densità (ISU) Progetto

Per soddisfare le esigenze dei dispositivi miniaturizzati, Supportiamo 6-20 design a tavola HDI, Utilizzo della tecnologia di perforazione VIA e laser cieca/sepolta per ottenere un routing preciso con larghezza/spaziatura della linea ≤3mil. Questa capacità è ideale per applicazioni ultrasolite come moduli di comunicazione 5G e dispositivi indossabili intelligenti.

Integrità del segnale ad alta velocità (E) Ottimizzazione

Utilizzo di strumenti di simulazione del segnale HyperlyNX, Affrontiamo la corrispondenza dell'impedenza e la soppressione del crosstalk nella trasmissione del segnale ad alta frequenza di livello GHZ. Soprattutto nelle schede madri del server e alle schede acceleratori di intelligenza artificiale, Assicuriamo che il ritardo del segnale sia controllato entro ± 5ps e i tassi di errore di bit rimangono al di sotto di 1E-12.

Gestione termica e design EMC

Combinando l'analisi della simulazione termica e l'ottimizzazione della compatibilità elettromagnetica, Utilizziamo schede a base di rame e VIA termica impilata per moduli ad alta potenza e sistemi di trasmissione automobilistica, ridurre l'aumento della temperatura di 15%-30%. Inoltre, I nostri layout di strati di schermatura EMI garantiscono la conformità al CISPR 25 standard.

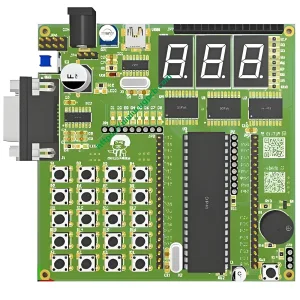

Mostraia di tipiche custodie di progettazione PCB

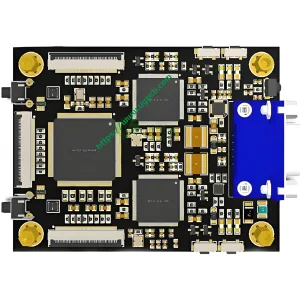

Caso 1: Caricatore di bordo (OBC) Main Control Board per nuovi veicoli energetici

- Sfondo: Il client richiedeva un OBC compatto a supporto di una piattaforma ad alta tensione da 800 V, Integrazione della conversione DC/AC bidirezionale e può essere comunicativa all'interno di un'area della scheda da 150 mm × 100 mm.

- Soluzione: È stata utilizzata una scheda FR4 a 4 strati, con motivi di potenza e segnale separati durante il layout. I loop di azionamento MOSFET sono stati ottimizzati attraverso la simulazione per ridurre il rumore di commutazione, e sono stati aggiunti termici metallizzati tramite array per garantire un aumento della temperatura di ≤40 ℃ sotto la corrente continua 30A.

- Risultato: Il design ha superato i test EMC di livello automobilistico al primo tentativo, raggiungendo un rendimento di produzione di massa di 99.2%. È ora in produzione in serie per un produttore di veicoli per veicoli energetici principali leader.

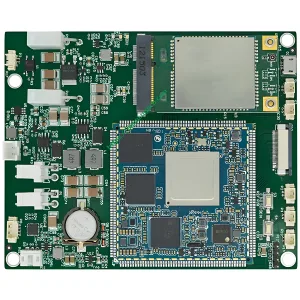

Caso 2: Gateway di calcolo dei bordi IoT industriale

- Sfida: Soppressione di interferenza multi-banda per le porte Ethernet a doppia gigabit e un Wi-Fi 6 modulo, insieme alla stabilità attraverso un ampio intervallo di temperatura da -40 ℃ a 85 ℃.

- Punti salienti del design: È stata utilizzata una struttura di stack-up a 6 strati, con il routing stripline per isolare le aree RF. Sono stati impiegati condensatori ceramici e resistori di deriva a bassa temperatura per abbinare i coefficienti di espansione termica, mentre gli strozzature in modalità comune e gli array di TV sono stati aggiunti per migliorare l'immunità a 4kv.

- Risultato: Il prodotto ha raggiunto IEC 61000-4-5 certificazione e manifestazioni zero dimostrate in un progetto di fabbrica intelligente con oltre 100,000 nodi.

Servizi end-to-end che potenziano i clienti

Dalla progettazione schematica e layout all'output di file Gerber, Forniamo servizi di progettazione e produzione di PCB unici, Collaborare con i team di assemblaggio PCBA per completare la verifica della produzione SMT. Il nostro sistema PLM garantisce il controllo della versione e la tracciabilità del cambiamento, Ridurre i cicli di progettazione di 20%-35%. Per requisiti di substrato specializzato che coinvolgono PEVCD (Deposizione di vapore chimico potenziata dal plasma) processi, Collaboriamo con i fornitori di materiali PCB per personalizzare i laminati rivestiti di rame con costanti dielettriche regolabili (Non so), Guidare l'innovazione in scenari ad alta frequenza e ad alta terma.

Valore di collaborazione e riconoscimento del settore

Abbiamo consegnato 5,000 Progetti di progettazione PCB, con 32% Essere prodotti ad alta affidabilità per elettronica automobilistica e dispositivi medici. I nostri clienti includono Global Top 50 produttori di elettronica. Andare avanti, Continueremo a investire in tecnologie all'avanguardia come il routing assistito e la co-progettazione della struttura PCB 3D per offrire soluzioni per le prestazioni più elevate per i nostri clienti.

LOGO UGPCB

LOGO UGPCB

WeChat

Scansiona il codice QR con WeChat