Structure of the High-Frequency Hybrid Splint

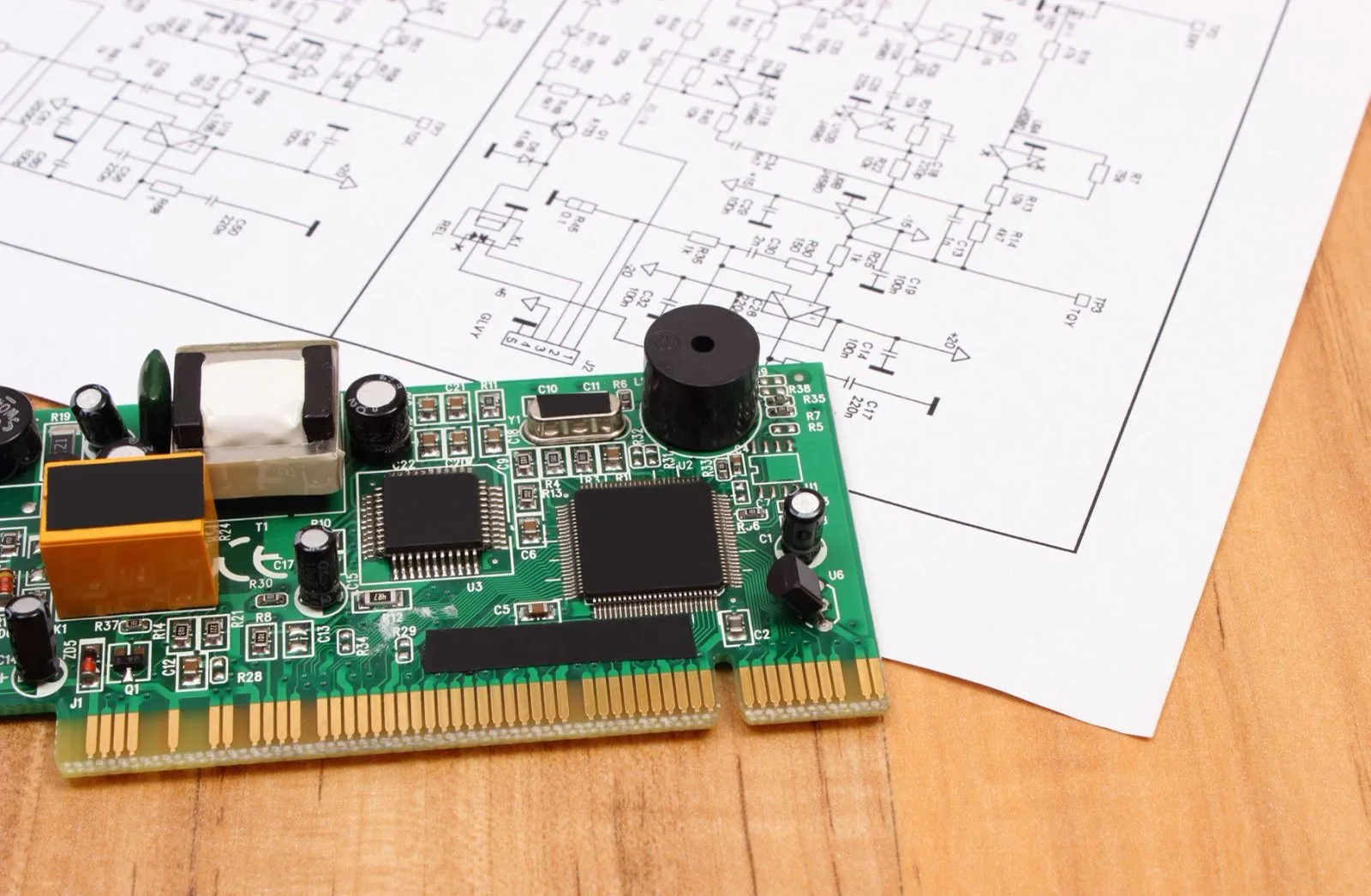

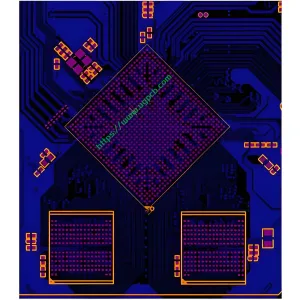

Base Plate and Layers

The high-frequency hybrid splint includes a base plate, which is folded and positioned on the first inner wire layer, the first outer wire layer, and the top surface of the solder mask ink layer from bottom to top in order. The second layer of the solder resist ink layer is also present.

Substrate Composition

The substrate includes a high-frequency area and an auxiliary area. The auxiliary area is fixed, and the inlay in the high-frequency area should be located at a fixed position.

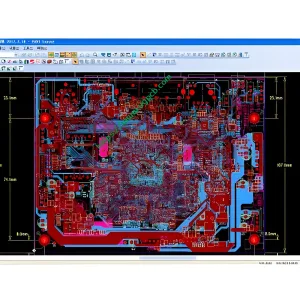

Utility Model of the High-Frequency Hybrid Splint

Division of the Splint

The utility model provides a high-frequency hybrid splint that is divided into two parts: a high-frequency area and an auxiliary area. It provides mechanical support.

Independent Arrangement of the High-Frequency Area

The utility model discloses that the high-frequency area is independently arranged, and only the high-frequency area is made of high-frequency materials. This minimizes the use of high-frequency board materials and reduces production costs while satisfying high-frequency signals.

Product Specifications

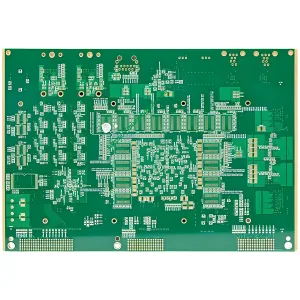

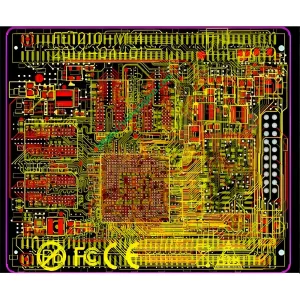

Classification and Layers

- High Frequency Hybrid Product Classification Layers: 6 Strati

Material and Dimensions

- Used Board: RO4350B + FR4

- Spessore: 1.6mm

- Misurare: 210mm x 280mm

Surface Treatment and Aperture

- Trattamento superficiale: Gold-plated

- Minimum Aperture: 0.25mm

Application and Features

- Applicazione: Comunicazione

- Caratteristiche: High Frequency Mixed Pressure

LOGO UGPCB

LOGO UGPCB