Panoramica

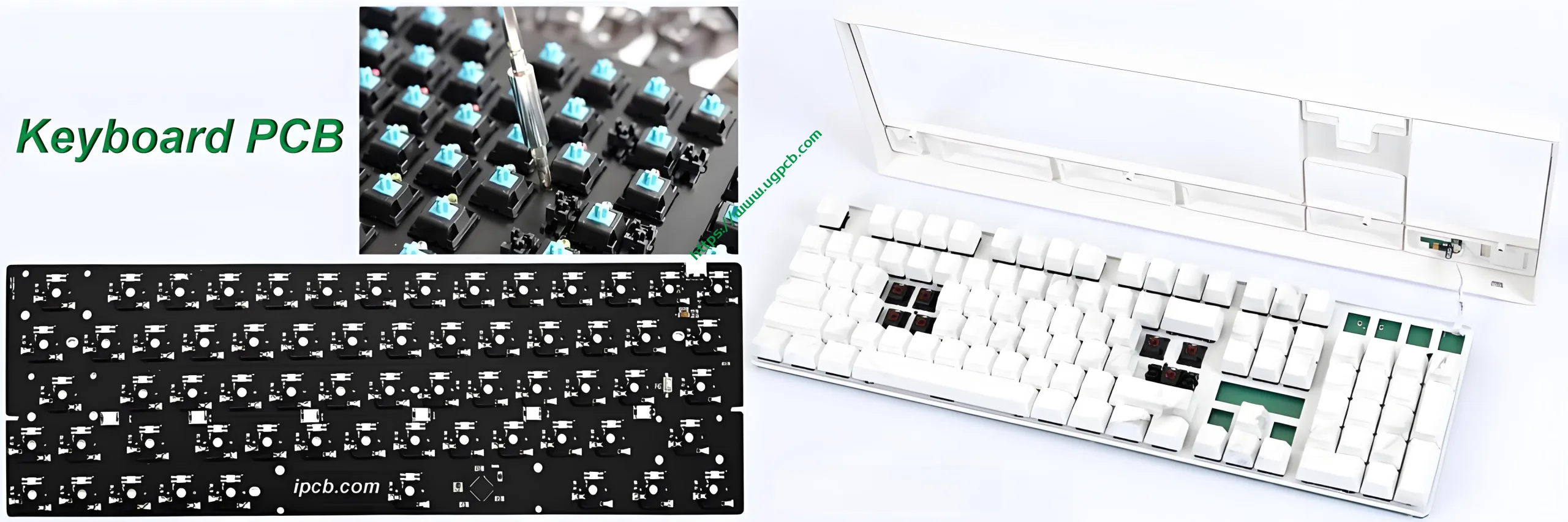

The Keyboard PCB is a fundamental component in modern keyboard assemblies, serving as the backbone that connects various switches, buttons, and LEDs to the computer system. It is designed specifically to handle the signals generated by user inputs, ensuring smooth and responsive operation. This PCB model combines durability with efficiency, making it a reliable choice for various keyboard applications.

Composizione materiale

The Keyboard PCB is crafted from high-quality materials to ensure robustness and reliability.

The primary materials used include:

FR-4

A flame-retardant epoxy glass cloth laminate known for its electrical insulation properties, resistenza meccanica, e resistenza al calore.

PI (Polyimide)

A flexible and lightweight material offering excellent insulation and high temperature resistance, suitable for more compact and flexible designs.

Aluminum

Provides enhanced thermal conductivity and mechanical stiffness, aiding in heat dissipation and durability.

Performance Specifications

The Keyboard PCB boasts impressive specifications tailored to meet the demands of modern keyboard manufacturing:

Layer Count

2Strato, allowing for complex circuitry while maintaining a cost-effective design.

Spessore finito

1.0-1.2mm, ensuring a balance between structural integrity and lightweight design.

Spessore del rame

1OZ, providing sufficient conductivity for reliable signal transmission.

Trattamento superficiale

OSP (Organic Solderability Preservatives), enhancing solderability and protecting the copper circuitry from oxidation.

Min Trace/Space

6mil, enabling dense circuit patterns for advanced functionality in a limited space.

Design strutturale

The PCB’s structure is meticulously engineered to optimize performance and manufacturability:

It features a compact layout with well-defined traces and spaces, minimizing interference and ensuring signal integrity.

The use of different materials (FR-4, PI, Aluminum) allows for customization based on the specific requirements of the keyboard design.

Distinctive Features

The Keyboard PCB stands out due to its unique characteristics:

Versatility

Available in various colors (Blue/White/Black/Green) to match different aesthetic preferences and design themes.

High Durability

Constructed with materials that resist wear and tear, ensuring long-lasting performance.

Optimal Signal Conduction: Thanks to its 1OZ copper thickness and precise trace/space dimensions, it ensures fast and accurate signal transmission.

Processo di produzione

The manufacturing of the Keyboard PCB involves several meticulous steps:

Progetto

The PCB layout is designed using specialized software, incorporating all necessary components and traces.

Material Preparation

The chosen substrate (FR-4, PI, or Aluminum) is prepared and cut to size.

Fabbricazione

The PCB is etched, perforato, and plated according to the design specifications.

Trattamento superficiale

The copper circuitry is coated with OSP to enhance solderability.

Controllo di qualità

Each PCB undergoes rigorous testing to ensure it meets all performance and quality standards.

Final Assembly

The PCB is integrated into the keyboard assembly, ready for use.

Application Scenarios

The Keyboard PCB is ideal for a wide range of applications:

Gaming Keyboards

Its high conductivity and durability make it perfect for handling the rapid and repeated keystrokes required in gaming.

Office Keyboards

Its reliable performance and aesthetic versatility suit office environments where efficiency and professionalism are key.

Custom Keyboards: Its customizable nature allows for integration into bespoke keyboard designs tailored to specific user needs and preferences.

By leveraging advanced materials and precision manufacturing techniques, the Keyboard PCB ensures that every keystroke is registered accurately and efficiently, enhancing the overall user experience across various applications.

LOGO UGPCB

LOGO UGPCB