Overview of Small Batch Purchasing

Small batch purchasing is a crucial aspect of time-based purchasing. Unlike traditional procurement models, time-based production necessitates reduced production batches, leading to the need for small batch purchases of materials. Tuttavia, this approach increases transportation costs and logistical challenges, particularly with long-distance suppliers.

Batch Procurement

Batch procurement involves the centralized purchasing of small-amount items under specific conditions:

- Single items below the bidding amount and purchased in small quantities by individual units

- Items frequently needed by various government units at the same level

- Single items with low prices but large quantities

Procurement methods may include inquiry procurement, bidding procurement, or negotiation procurement.

Challenges in Small Batch PCBA Assembly Supplier

Minimal Packaging Problem

In electronic component procurement, parts are shipped with a minimum package base. For small components like transistors, condensatori, and resistors, this base can range from hundreds to thousands. In trial production, the required quantity may be minimal, leading to waste and high R&D costs. This issue extends to small parts beyond electronic components.

Minimum Batch Problem

Small batch purchases can also face the minimum batch problem. Due to process or equipment requirements, products cannot be produced in the smallest unit but must be produced in batches. This results in difficulties for small batch procurement of products requiring a minimum production unit.

Minimum Cost Problem

Some products do not have minimum batch requirements for processes and equipment, but certain processes have a fixed cost regardless of the production quantity. Per esempio, chemical potions used in production have the same consumption for single-piece and full-load production, leading to higher unit costs for small batch production.

Control Methods for Small Batch Procurement

Seek an Alternative

When small batch procurement is costly and components are common, consider seeking alternatives from similar manufacturers. This can reduce procurement costs by utilizing excess materials from other manufacturers.

Involve Technicians in Procurement

For new product R&D and trial production, involving technicians in procurement can help reduce batch sizes. Technicians know the exact quantities needed, and direct communication with suppliers can result in smaller, cost-effective batches.

Form Strategic Alliances with Suppliers

Forming strategic alliances with suppliers can also reduce small-volume procurement costs. This long-term partnership allows for cost savings and fulfillment of obligations, even for small batches.

Joint Procurement

Joint procurement involves small and medium-sized enterprises pooling their purchasing power to gain a favorable position and expand purchase batches. This can reduce procurement costs and increase risk prevention abilities.

Third-Party Procurement

Third-party procurement outsources product or service procurement to a third-party company. This can provide more value and purchasing experience, helping companies focus on core competencies. Procurement alliances can convert small batches into larger quantities, reducing costs significantly.

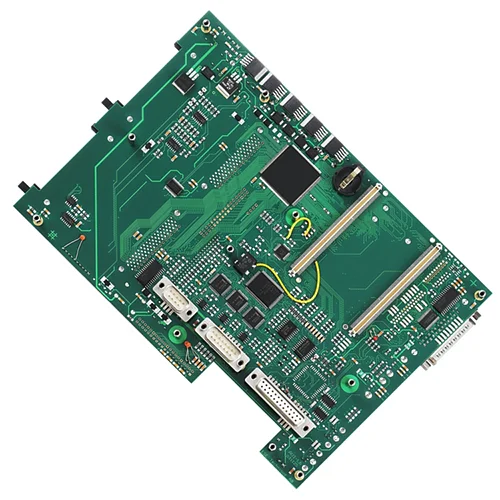

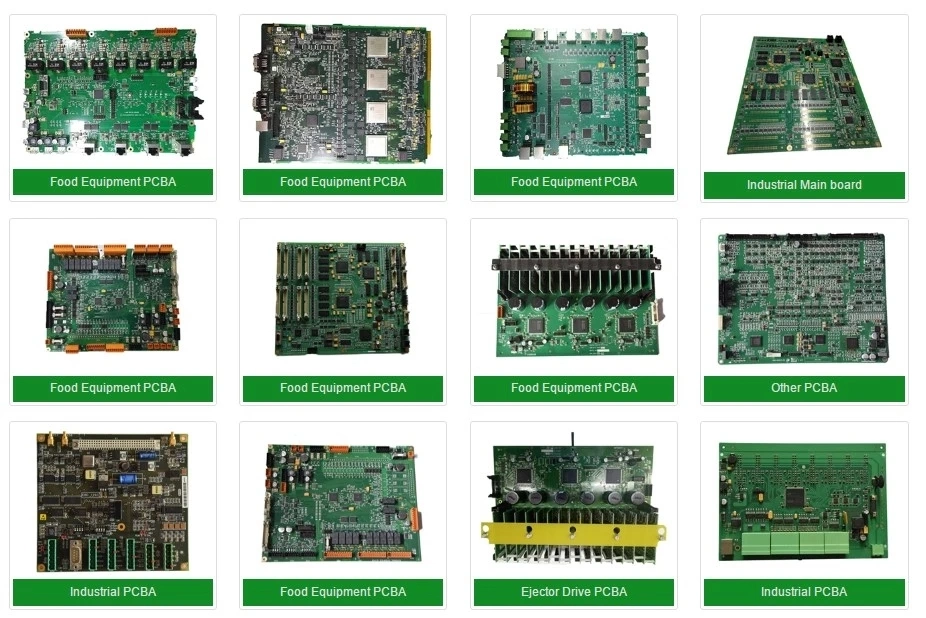

UGPCB Supports Small Batch PCBA Supplier Business

UGPCB is a professional PCBA one-stop assembly factory that supports small batch PCBA supplier business. Welcome to place an order with us.

LOGO UGPCB

LOGO UGPCB