Through Hole Plug Carbon Ink PCB Material

The Through Hole Plug Carbon Ink PCB is crafted from FR-1,94v0 material, a flame-retardant grade that meets UL 94V-0 standard. This material combines fiberglass and epoxy resin, providing excellent electrical insulation, resistenza meccanica, e resistenza al calore. The choice of FR-1,94v0 ensures the PCB’s durability and reliability in various applications.

Prestazione

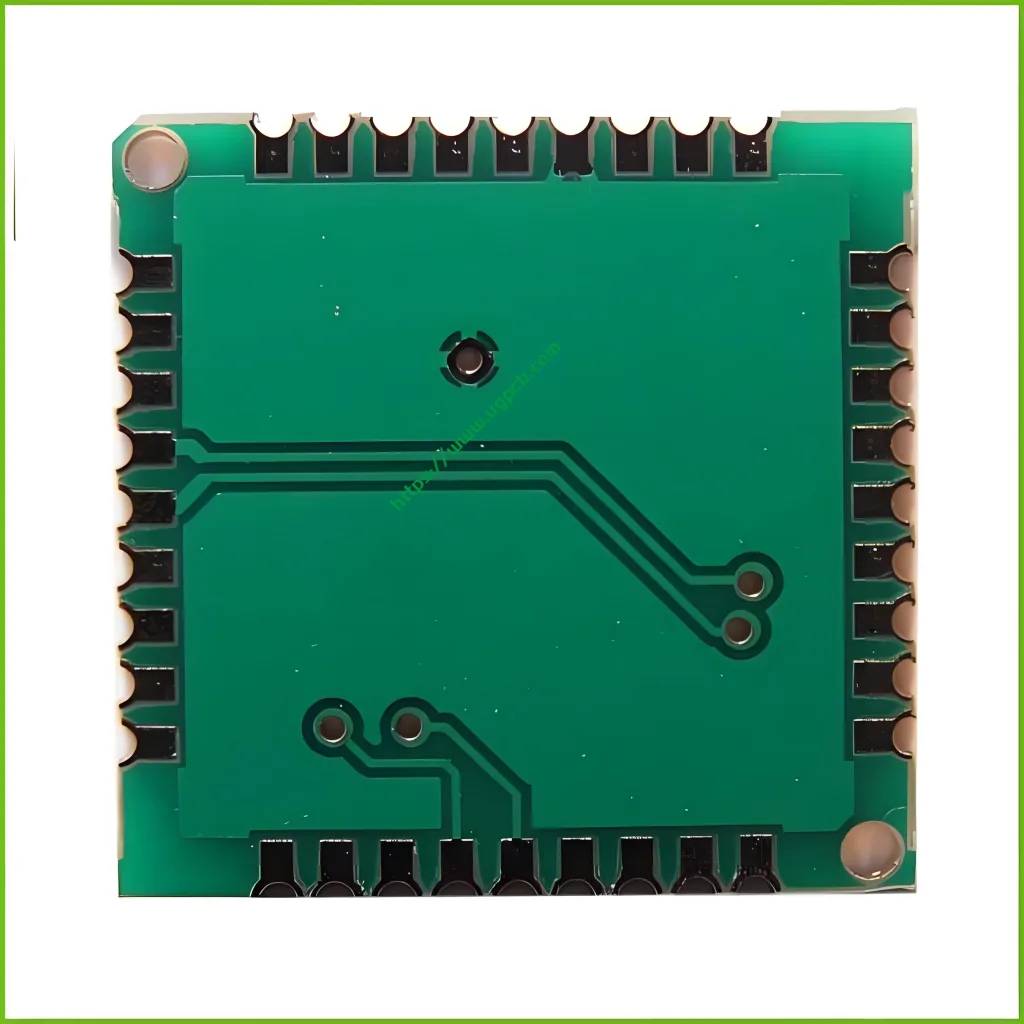

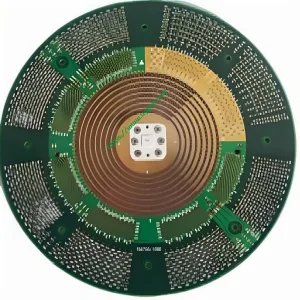

The PCB features a single copper layer and an additional carbon ink layer, offering versatility in circuit design and functionality. With a finished thickness of 1.0mm, it maintains a compact form factor while ensuring sufficient structural integrity. The copper thickness of 1OZ provides good conductivity and current carrying capacity, essential for reliable performance in electronic circuits.

Struttura

The PCB comes in a green/white color, enhancing its visual appeal and ease of inspection during manufacturing and assembly processes. The surface treatment of Organic Solderability Preservatives (OSP) protects the copper surface from tarnishing and oxidation, ensuring good solderability during component attachment.

Special Characteristics

The defining characteristic of the Through Hole Plug Carbon Ink PCB is its plug carbon ink process. This special process involves filling through-holes with carbon ink, creating electrical connections between circuits on different layers without the need for plated through-holes. This technique simplifies manufacturing, reduces cost, and allows for more compact designs. Carbon ink also provides a high degree of flexibility and conductivity, suitable for various applications requiring precise control over electrical properties.

Processo di produzione

The production of the Through Hole Plug Carbon Ink PCB involves several key steps:

- Material Preparation: FR-1,94v0 material is cut to size and prepared for processing.

- Circuit Patterning: The copper circuitry is etched onto the FR-1,94v0 base material using photolithography techniques.

- Carbon Ink Plugging: Through-holes are filled with carbon ink to create electrical connections.

- Trattamento superficiale: The OSP process is applied to protect the copper surface.

- Solder Mask Application: A protective solder mask is applied to the PCB surface to prevent soldering errors and enhance durability.

- Final Assembly and Testing: Components are attached, and the PCB is tested to ensure functionality and reliability.

Application Scenarios

The Through Hole Plug Carbon Ink PCB is ideal for key products such as remote control PCBs. Its compact design, reliable electrical connections, and cost-effective manufacturing process make it a perfect fit for remote control applications. The PCB supports complex circuitry and high component density, enabling advanced functionality in remote controls, such as touch-sensitive buttons, LCD displays, and wireless communication capabilities. Whether used in home entertainment systems, industrial controls, or automotive applications, the Through Hole Plug Carbon Ink PCB ensures reliable performance and user satisfaction.

LOGO UGPCB

LOGO UGPCB