ARLON has more than 50 years of experience in PTFE-based microwave laminates, and more than 30 years of experience in polyimide laminates and special epoxy resin laminates. Compared with the traditional standard FR-4 material, its laminate products have more professional electrical, thermal, mechanical or other performance characteristics, and are widely used in various high-frequency PCB applications and other special markets.

ARLON microwave PCB substrate.

Arlon PCB Common Materials

92ML, AD250C, AD255C, AD260A, AD300C, AD320A, AD350A, AD430, AD410, AD450, AD600

CLTE, CuClad217, CuClad233, CuClad250, DiClad880, DiClad870, DiClad527, DiClad917, DiClad933

Arlon PCB

With the rapid development of the communication market and the continuous innovation of product technology, the requirements of high-frequency and high-speed signals on PCB materials are also increasing, but the market requires that the product cost be kept at a lower level Both high-frequency PCB designers and PCB manufacturers are faced with the choice of appropriate PCB materials to meet the signal characteristics of high-frequency PCB. Inoltre, PCB manufacturing and processing are easy and PCB cost is low.

Conditions for Selection of High-Frequency PCB Materials

1. Dielectric constant, which is usually determined according to specific circuit design and function, directly affects PCB structure (thickness, characteristic impedance, ecc.)

2. Loss, which is a more stringent requirement in high-frequency design, can be adjusted according to the dielectric constant, but not around the loss

3. The thickness change and the thickness of the base material are also important factors to determine the characteristic impedance. Allo stesso tempo, in the high-frequency design, they also affect the interference of interlaminar signals The more choices, the more convenience for designers

4. Consistency of dielectric constant

5. Machinability of materials, which determines PCB processing cost

6. The thermal expansion coefficient of materials directly affects the multi-layer processing

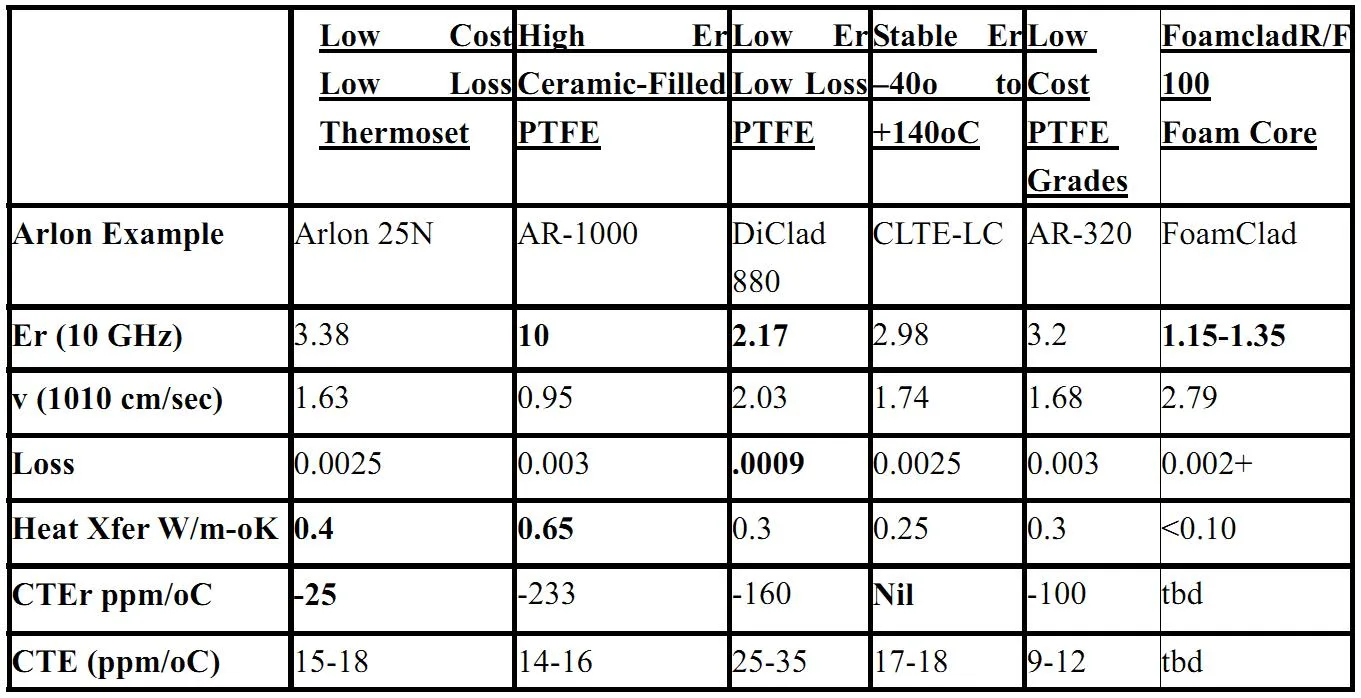

ARLON common substrate parameter table

Material characteristics of arlon pcb series PCB

ARLON 25N/25FR series materials belong to ceramic-filled paraffin and glass fiber-reinforced materials. Due to the symmetry of the paraffin molecular structure itself, there is no obvious polar group, which makes it show low loss characteristics in the environment of high-frequency electromagnetic waves. This material combines the characteristics of low loss and low expansion of ceramic filling materials

Material characteristics of ARLON series PCB

Electrical characteristics of arlon pcb series materials

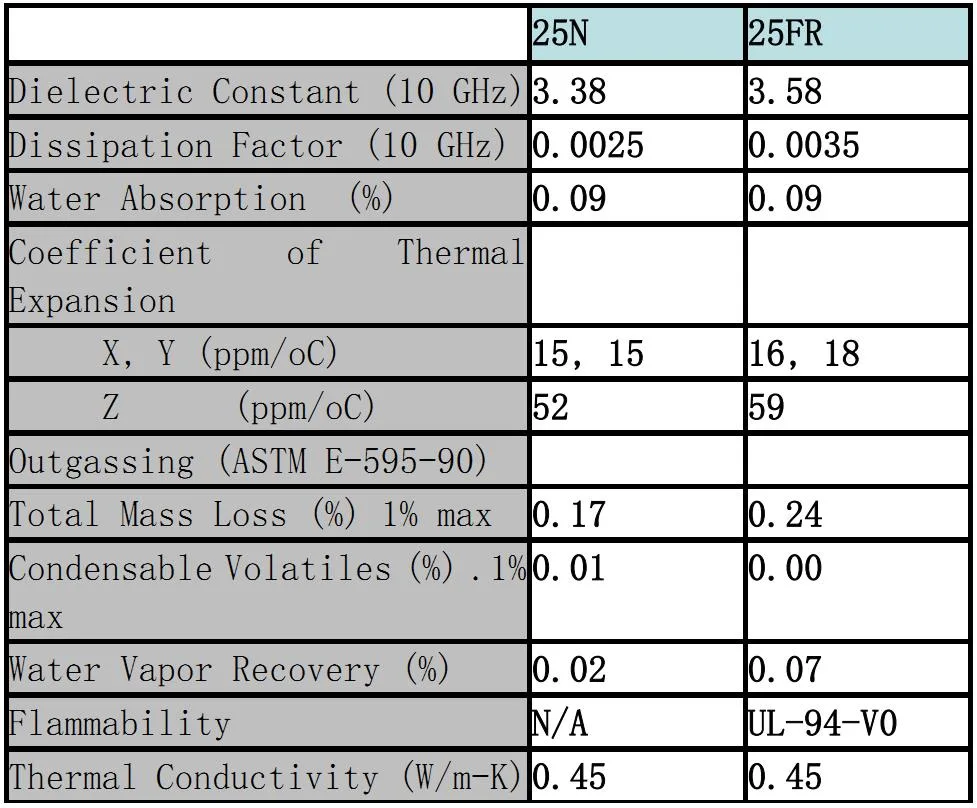

25N/FR has good electrical characteristics, mainly shown in low dielectric Changshu, low loss factor and relatively stable dielectric constant under temperature change As an ideal material for wireless and digital communications, its applications include mobile phones, converters, low noise amplifiers, ecc

ARLON 25N/25FR parameter sheet

Arlon PCB manufacturing process precautions

Although 25N/FR can adopt a process similar to FR4, it is not FR4 after all. Pay attention to the following aspects during processing

1. Operation: 25FR/N is softer than FR4. Pay attention to operation, and guide plate can be used

2. Dimensional stability: 25FR/N shrinks more than FR4. For different designs and structures, appropriate expansion ratio should be found

3. It is better to browning the inner layer before laminating. Before laminating, vacuum for 30 minuti, control the temperature rise at 2-3C per minute, and cure at 180C for 90 minuti. The cooling rate of cold pressing should be less than 5C per minute

4. Hard cover plate and base plate shall be used for drilling to reduce burrs The drilling parameters can be adjusted on similar holes of FR4. The existence of ceramic powder may reduce the life of the bit

5. Porous pretreatment, potassium permanganate and plasma can effectively remove dirt. No special process is required for copper electroplating

6. For surface coating, 25N/FR can adopt any surface coating technology, such as chemical tin, chemical nickel gold, electrotinning, and hot air leveling. Tuttavia, it should be noted that when hot air leveling is used, it needs to be baked at about 110C for one hour in advance

7. For contour milling, it is better to use a double groove milling cutter. For V-cutting, it will be more efficient to use 30 degrees

With the development of high-speed signal, high-frequency arlon pcb materials are more and more widely used.

LOGO UGPCB

LOGO UGPCB