The Essential Role of PCBs in Electronics

エレクトロニクス製造の領域で, プリント基板 (プリント基板) 重要なコアコンポーネントとして機能します. 電子機器の神経中心のように振る舞います, さまざまなコンポーネントを接続します, シームレスな電気と情報の流れを確保します. But have you ever pondered why the thickness of the copper layer on these PCBs is expressed in ounces? This article delves into this intriguing detail, exploring the science and art behind determining PCB copper layer thickness.

Why Copper Thickness Matters

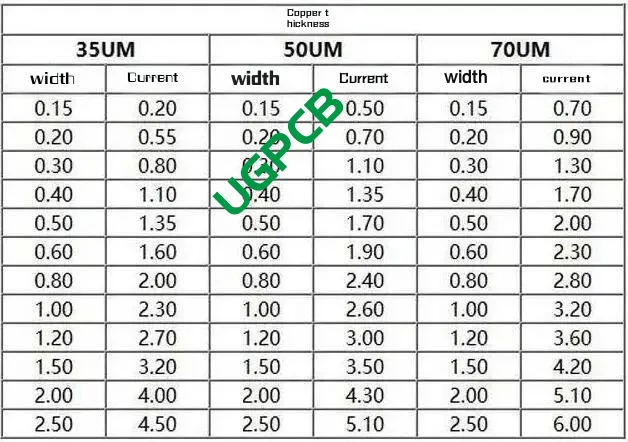

Consider the high-tech gadgets like smartphones or laptops; each houses one or more PCBs. A critical aspect of these boards is the thickness of their copper foil, impacting not just conductivity and heat dissipation but also the product’s durability and cost. The choice of expressing copper thickness in ounces over length units simplifies calculations related to density and conductivity, making design and manufacturing more straightforward. Ounces offer a direct correlation with conductivity—more weight means better conductivity due to a higher number of copper atoms.

Standardizing Thickness for Universality

The standardization of using the ounce unit in PCB manufacturing fosters clear communication and collaboration among designers and manufacturers, avoiding confusion across diverse materials and processes.

Standard PCB Copper Layer Thicknesses

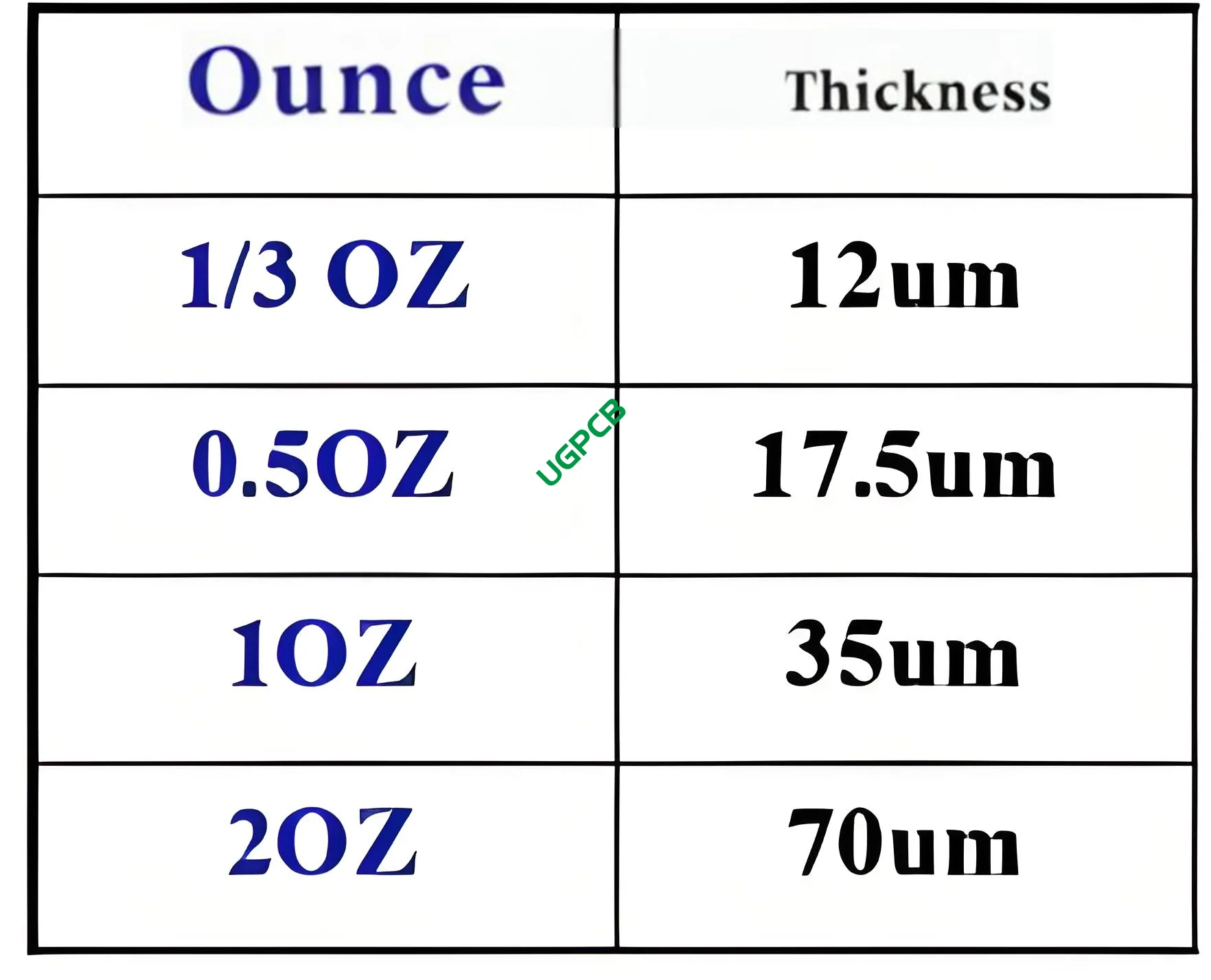

Standard PCB copper thicknesses are categorized into several specifications, 含む 1 ounce (approximately 35 ミクロン), 2 ounces (について 70 ミクロン), そして 3 ounces (around 105 ミクロン). These standards cater to different application needs:

- Single-sided and double-sided PCBs typically use a 1-ounce copper layer.

- Multi-layer boards feature inner layers with 1/2 または 1/3 ounce copper, while outer layers may vary between 1, 1/2, または 1/3 ounce.

- Special applications requiring higher current capacities might necessitate up to 2 または 3 ounces per square foot.

Balancing Thickness for Performance and Cost

While thicker copper layers enhance conductivity and heat dissipation, they also increase weight, 料金, and manufacturing complexity. したがって、, selecting the appropriate thickness involves a balance between application-specific requirements and cost considerations.

Impact on Circuit Performance

Copper layer thickness directly influences a circuit’s conductivity and heat dissipation efficiency, crucial for stable and reliable electronic equipment operation. Adequate copper thickness bolsters the PCB’s mechanical strength and longevity, particularly in challenging environments.

Embracing Technological Advancements

As technology progresses and electronic devices become more sophisticated, so do the demands on PCBs. Future advancements will likely lead to smaller, more efficient devices, with green manufacturing and recyclability gaining prominence. In this landscape, mastering the nuances of PCB copper layer thickness selection becomes increasingly important for industry practitioners and enthusiasts.

結論: A Crucial Link in Electronics Progress

Understanding and innovating within the realm of PCB copper layer thickness is integral to advancing electronics manufacturing. By grasping the underlying principles and continuously exploring new frontiers, we contribute to the evolution of electronic equipment, pushing the boundaries of what’s possible in this dynamic field.

UGPCBのロゴ

UGPCBのロゴ