PCB アセンブリ

現代の電子機器におけるPCBAの本質

電子工学の広大な分野で, プリント基板 (印刷回路基板アセンブリ) 製品は複雑なニューラルネットワークとして機能します, 電子デバイスにシームレスに統合されて、機能とインテリジェンスを提供する. このドメインのコアを紹介します, 当社のウェブサイトで専用のPCBA製品ケーススタディセクションを開始しました, 精密な製造と革新の旅に出るように誘う.

プリント基板設計: イノベーションの青写真

すべての注目すべきPCBA製品は、細心の注意を払って作成されたPCBデザインの青写真から始まります. 私たちのケーススタディで, PCB設計フェーズは、繊細な技術的なアートワークとして描かれています. エンジニアは電流の流れを細心の注意を払ってマッピングし、各コンポーネントをミクロンレベルの精度で配置します, 最適な配置と機能を確保します. これらの青写真の詳細な分析を通じて, 回路図の構想からボードレイアウトまでの完全なプロセスを明らかにします, 回路計画の実証, 空間最適化, また、信号の整合性は、製品の要件を満たすように調整されています. この基礎作業は、その後のPCB製造およびPCBAアセンブリプロセスの舞台を設定します.

生産の精度: デザインから現実まで

デザインを有形の製品に変換することは、エンジニアリングの卓越性の証です. 私たちの技術リソースは、鮮明な説明とビジュアルを通じてPCBとPCBAの生産の各段階を分かります. 原材料が正確に切断される方法を目撃してください, ドリル, 最先端の機器を使用した銅メッキ, 高品質のPCB基板に変換されます.

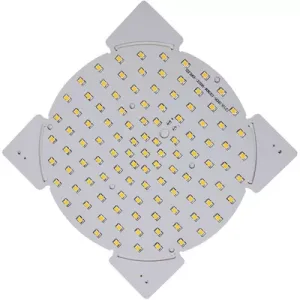

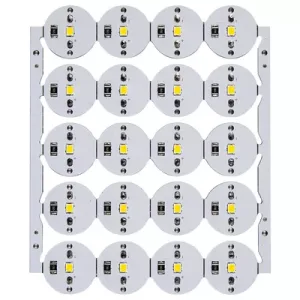

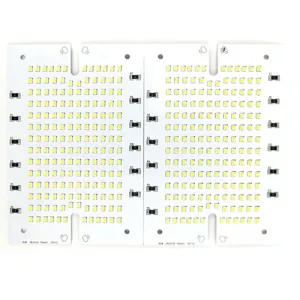

紹介されたPCBA製品, SMTを使用して組み立てられました (表面実装技術) またはtht (スルーホールテクノロジー), 精密エンジニアリングを例示します. UGPCBの施設で, 自動ロボットアームは、コンポーネントの配置におけるミクロンレベルの精度を実現します, 高度なはんだ付け技術は、回路とコンポーネントの間にシームレスな接続を作成します. その結果、完全に機能するPCBAの傑作のコレクションが生まれました, それぞれが技術的な専門知識と産業芸術性のブレンド.

品質保証: 厳格な基準

品質は、PCBAの信頼性の基礎です. 生産のマイルストーンを強調していない, 私たちのケーススタディは、厳密な品質管理プロセスを強調しています. 厳しい材料の選択やリアルタイムの生産監視から、包括的な最終検査まで, すべてのステップは、国際基準に準拠しています. X線イメージングなどの高度な技術, あおい (自動光学検査), およびICT (回路内テスト) 各PCBA製品が耐久性とパフォーマンスの最高水準を満たしていることを確認してください, 重要な電子アプリケーションで信頼できるコアコンポーネントにする.

インスピレーションと革新の旅

このセクションでは、技術的な洞察以上のものを提供しています。エレクトロニクス製造の将来についての反省を招きます. 各ケーススタディは、イノベーションが職人技に合ったストーリーを伝えています, テクノロジーは芸術性と融合しています. PCBAの世界を探索してください, 一見普通の製品が並外れた創造性を体現している場所, 現代の電子機器の輝きと変革力を祝う.

UGPCBのロゴ

UGPCBのロゴ

微信

WeChat で QR コードをスキャンします