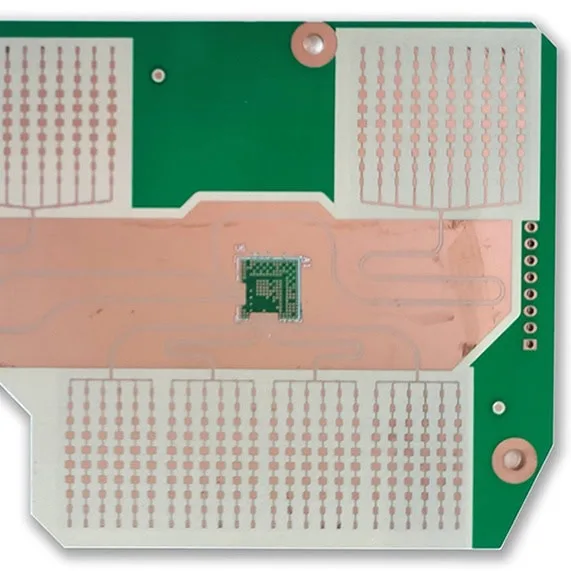

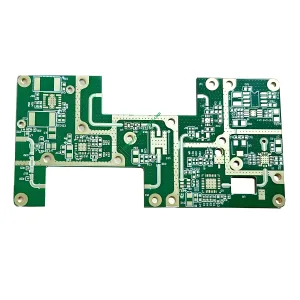

RO3003 Ceramic Hybrid High Frequency PCB Overview

The RO3003 Ceramic Hybrid High Frequency PCB is a premium printed circuit board designed specifically for high-frequency applications. It combines the advanced electrical properties of Rogers RO3003 material with the cost-effectiveness and versatility of FR4, creating a robust and reliable substrate. This PCB is ideal for guided wave radar level gauges (GWRLGs) and other high-performance applications.

材料構成

The RO3003 Ceramic Hybrid High Frequency PCB is crafted from a unique blend of Rogers RO3003 and FR4 mixed dielectric materials. This combination offers a balance of electrical performance, 料金, and reliability, making it suitable for a wide range of high-frequency applications.

性能特性

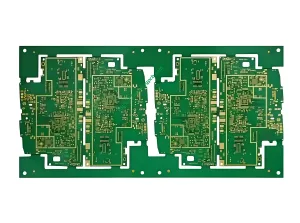

- レイヤー数: The PCB features a 6-layer design, providing ample space for complex circuitry and components.

- 誘電率 (D K): With a D K of 3.00 ± 0.04, the board exhibits consistent electrical performance across a wide frequency range.

- 仕上がり厚さ: The PCB has a finished thickness of 2.0mm, ensuring durability and structural integrity.

- 銅の厚さ: The 1oz copper thickness offers excellent conductivity and current carrying capacity.

- 誘電体の厚さ: The dielectric layer is 0.762mm thick, contributing to the board’s overall electrical performance.

- 熱伝導率: With a thermal conductivity of 0.43w/m.k, the PCB effectively manages heat dissipation, preventing overheating and component failure.

- 可燃性: The board meets the 94V-0 flammability rating, ensuring safety in various environments.

- 表面処理: The immersion gold surface treatment enhances conductivity and corrosion resistance, ensuring reliable performance over time.

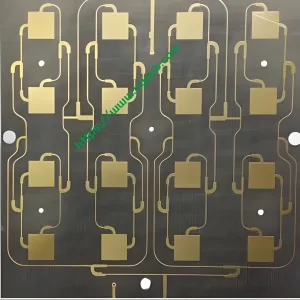

製造工程

The production of RO3003 Ceramic Hybrid High Frequency PCBs involves several precision steps:

- 材料の準備: Rogers RO3003 and FR4 materials are carefully selected and prepared for mixing.

- Mixing and Laminating: The materials are blended and laminated together under controlled conditions to form a uniform substrate.

- Circuit Design and Layout: The desired circuit patterns are designed and laid out using advanced CAD software.

- Manufacturing: The PCB is manufactured through a series of processes including etching, 掘削, and copper plating.

- 表面処理: The board undergoes immersion gold surface treatment to enhance conductivity and corrosion resistance.

- 品質管理: Each PCB undergoes rigorous testing to ensure it meets the specified performance standards.

アプリケーションシナリオ

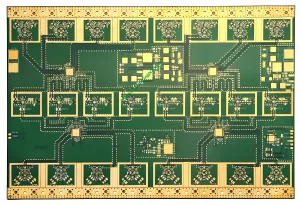

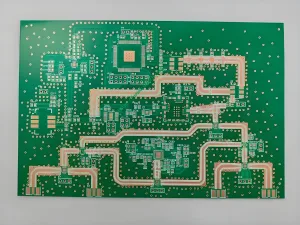

The RO3003 Ceramic Hybrid High Frequency PCB is ideal for use in guided wave radar level gauges (GWRLGs), where high-frequency performance and reliability are critical. The PCB’s exceptional electrical properties and robust design make it suitable for the following applications:

- High-Frequency Signal Transmission: The PCB supports high-frequency signal transmission with minimal loss, ensuring accurate and reliable level measurement.

- Complex Circuitry: The 6-layer design provides ample space for complex circuitry and components, enabling advanced functionality and performance.

- Harsh Environments: The PCB’s durability and flame resistance make it suitable for use in harsh environments, ensuring reliable performance even in challenging conditions.

要約すれば, the RO3003 Ceramic Hybrid High Frequency PCB is a versatile and high-performance solution for guided wave radar level gauges and other high-frequency applications. Its combination of electrical excellence, 耐久性, and reliability makes it an ideal choice for demanding applications.

UGPCBのロゴ

UGPCBのロゴ