樹脂プラグPCBの紹介

製品の概要

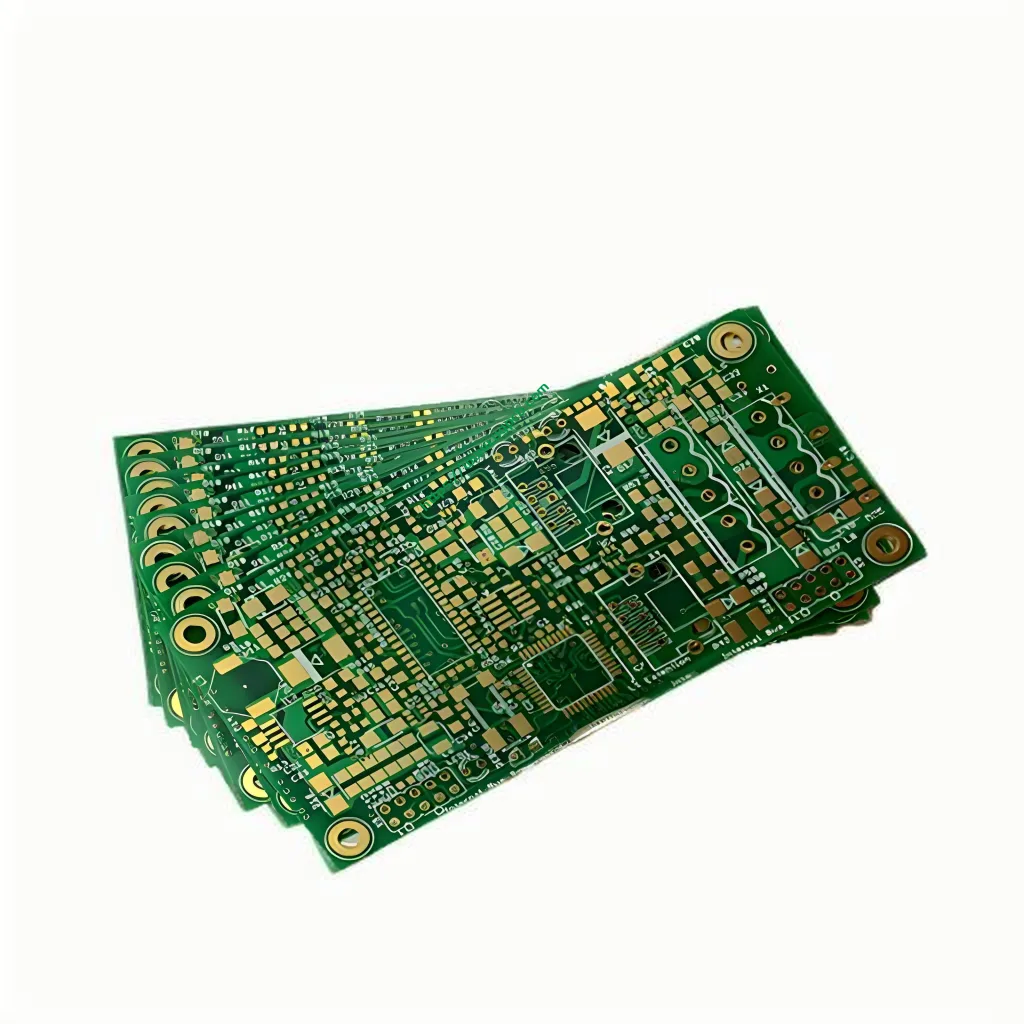

樹脂プラグPCBは、特殊なタイプの印刷回路基板です (プリント基板) 高性能電子アプリケーション用に設計されています. 高度な樹脂プラグ技術が組み込まれています, これにより、機械的な安定性と電気性能が向上します. このPCBは、スペースと信頼性が重要な要因であるデジタル製品で特に役立ちます.

目的とアプリケーション

樹脂プラグPCBの主な目的は、電子コンポーネントの取り付けと相互接続のための堅牢で信頼できるプラットフォームを提供することです. スマートフォンなどのデジタル製品で広く使用されています, 錠剤, ラップトップ, その他のポータブルデバイス. そのコンパクトな設計と高い耐久性により、正確さと効率を要求する最新の電子アプリケーションに最適です.

分類

樹脂プラグPCBは、いくつかの基準に基づいて分類できます:

- レイヤー数: このPCBにはあります 6 レイヤー, 複雑な回路設計と効率的なコンポーネント配置を可能にします.

- 材料構成: S1141素材から作られています, 優れた熱および機械的特性で知られています.

- 表面処理: 浸漬ゴールドトリートメントが特徴です, 優れた導電率と耐食性を提供します.

材料と建設

材料

樹脂プラグPCBは、S1141材料で作られています, 高強度と熱安定性のために選択されます. これにより、PCBはその構造的完全性を維持しながら、厳しい動作条件に耐えることができます.

建設の詳細

- レイヤー: PCBは構成されています 6 レイヤー, 複雑な回路設計のための十分なスペースを提供します.

- 仕上がり厚さ: PCBの厚さは1.2mmです, 空間効率と機械的強度の両方を最適化します.

- 銅の厚さ: 1/0.5オンスの銅層, PCBは、効率的な電気伝導率を保証します.

- 色: 緑と白で利用可能, さまざまなデバイスでの簡単な識別と美的統合を促進します.

性能特性

- 特別な技術: 樹脂プラグテクノロジーを使用すると、PCBの機械的安定性と電気性能が向上します, 高解放性アプリケーションに適しています.

- 最小トレース / 空間: PCBは、BGA 3MIL/3MILの最小トレースとスペースでファインピッチコンポーネントをサポートします, 高密度コンポーネント配置を有効にします.

製造工程

樹脂プラグPCBの製造プロセスにはいくつかの重要なステップが含まれます:

- 材料の準備: 最適なパフォーマンスのためにS1141材料の選択と準備.

- レイヤースタッキング: スタッキング 6 望ましい厚さと機能を実現するためのレイヤー.

- パターンエッチング: 化学エッチングまたはレーザー切断を使用して、正確な回路パターンを作成する.

- ラミネート加工: 高圧と温度の下で層を一緒に圧縮して凝集ユニットを形成する.

- メッキ: 良好な電気接続を確保するために銅メッキを塗布します.

- 表面処理: 導電率と耐食性を高めるために、浸漬金で表面を扱う.

- 品質管理: PCBがすべてのパフォーマンス仕様を満たすことを確認するために厳格なテストを実施する.

主な機能と利点

- 高い機械的安定性: 樹脂プラグテクノロジーは、並外れた機械的安定性を提供します, コンポーネント障害のリスクを軽減します.

- 優れた電気性能: PCBの設計により、一貫した信号伝送と最小限の干渉が保証されます.

- 耐久性: 高強度材料で作られています, 過酷な条件下でも長期的な信頼性を確保します.

- 多用途性: 適応可能な設計と材料特性により、幅広いデジタル製品に適しています.

使用シナリオ

樹脂プラグPCBは、高い信頼性とコンパクトな設計が重要なシナリオに不可欠です, のような:

- 家電: スマートフォンのパフォーマンスと耐久性の向上, 錠剤, ラップトップ.

- ウェアラブルデバイス: フィットネストラッカーとスマートウォッチの小型化と信頼性のサポート.

- カーエレクトロニクス: 車両の高度なドライバーアシスタンスシステムとインフォテインメントユニットを促進します.

- 産業用アプリケーション: 自動化および制御システムの正確な制御と監視を可能にする.

結論は, 樹脂プラグPCBは、PCBテクノロジーの大幅な進歩を表しています, 高い機械的安定性と優れた電気性能を組み合わせる. その堅牢な構造と高度な機能により、正確さと信頼性を必要とする最新のデジタル製品に理想的な選択肢になります. コンシューマーエレクトロニクスのパフォーマンスを向上させるか、重要な自動車アプリケーションをサポートしているかどうか, このPCBは、イノベーションとエンジニアリングの卓越性の証として際立っています.

UGPCBのロゴ

UGPCBのロゴ