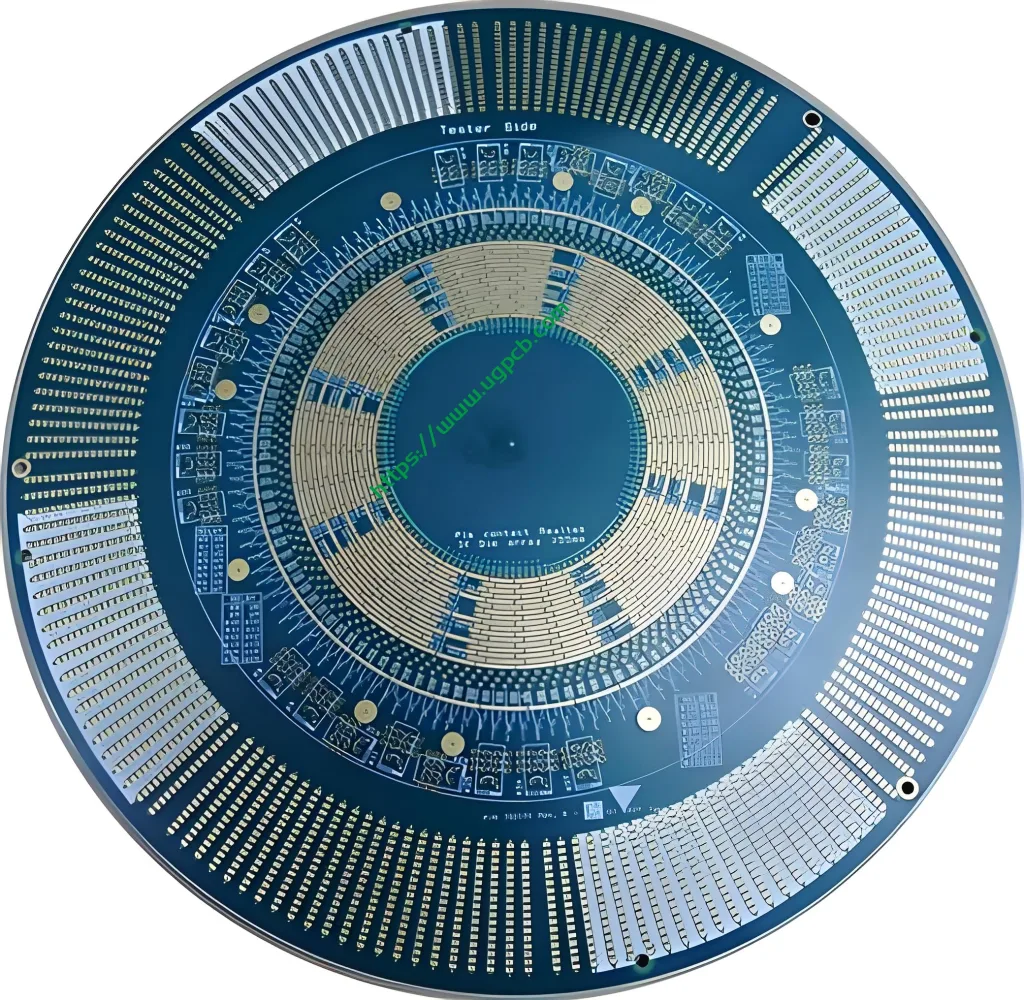

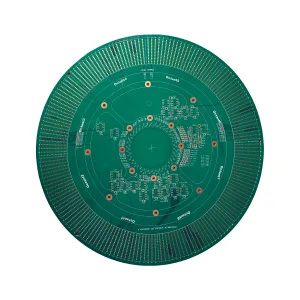

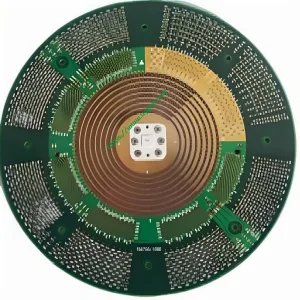

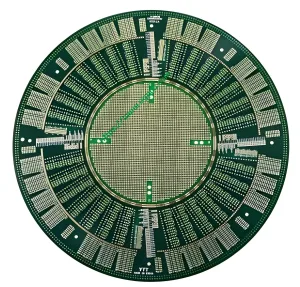

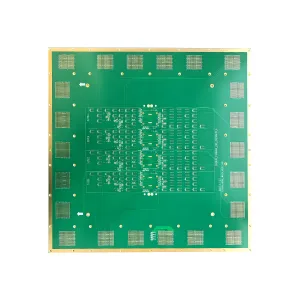

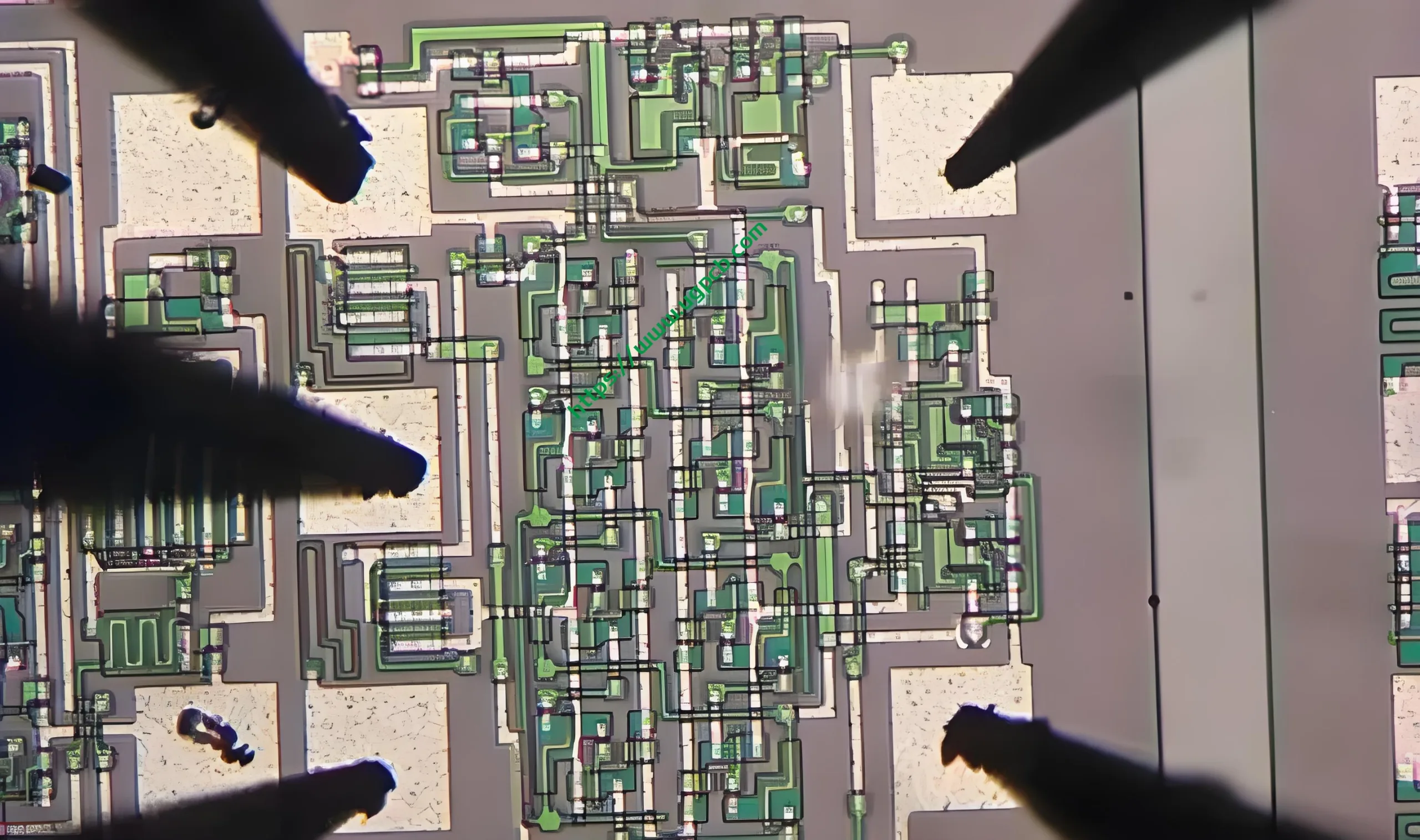

ATE Test Chip PCB Overview

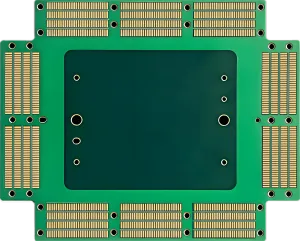

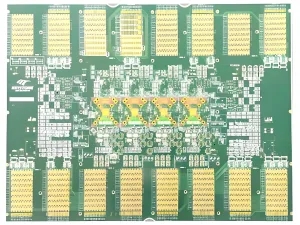

The ATE test chip PCB is a specialized プリント基板 designed for use in automated test equipment (食べた) systems for testing semiconductor chips. これ プリント基板 plays a crucial role in ensuring the quality and reliability of chips before they are integrated into electronic devices. Below is a detailed introduction to the ATE test chip PCB, 一般的な情報をカバーする, 分類, 材料, パフォーマンス, 構造, 特徴, 製造工程, およびアプリケーションシナリオ.

分類

ATE test chip PCBs are classified based on their layer count, 材料組成, および特定のアプリケーション要件. 今回紹介したモデルは, ATE test chip PCB, is a 12-layer PCB, indicating its complexity and ability to handle intricate testing scenarios.

材料構成

The ATE test chip PCB is constructed using isola 370hr material, a high-performance, high-reliability substrate known for its excellent electrical and thermal properties. This material ensures the PCB’s ability to withstand the demanding test conditions and provide stable performance.

性能特性

The ATE test chip PCB excels in several performance areas, 高電流容量を含む, 信号損失が少ない, 優れた熱管理. The use of 2OZ copper thickness for inner layers and 1OZ for outer layers enhances its electrical conductivity and thermal dissipation capabilities. さらに, the immersion gold (5u) surface finish provides superior corrosion resistance and solderability, ensuring reliable connections during testing.

構造設計

構造的に, the ATE test chip PCB features a board thickness of 3.0mm, providing a robust foundation for the complex circuitry and コンポーネント. The green color not only adds a visual distinction but also aids in inspection and troubleshooting processes.

特徴的な機能

The ATE test chip PCB stands out with its unique features, including its high layer count, advanced material composition, and immersion gold surface finish. これらの機能, combined with its precise design and manufacturing processes, make it an ideal choice for ATE chip testing applications.

製造工程

The production of ATE test chip PCBs involves a series of sophisticated steps:

- 材料の準備: The isola 370hr substrate is prepared and cut to the required dimensions.

- 銅ラミネート: 銅箔が基板にラミネートされます, with specific attention to the inner layer 2OZ and outer layer 1OZ thickness requirements.

- 回路パターニング: 精密エッチング技術を使用して、目的の回路パターンを銅箔上にエッチングします。.

- 層の積み重ねと積層: 複数の層を重ねて積層します, 正確な位置合わせと接合を保証する.

- 穴あけ加工とメッキ加工: 穴は、コンポーネントの取り付けと相互接続用に掘削されます, and then plated to enhance conductivity.

- 表面仕上げの塗布: The immersion gold (5u) coating is applied to provide corrosion resistance and solderability.

- 最終検査とテスト: PCB は仕様と性能要件への準拠を保証するために厳格な検査とテストを受けます.

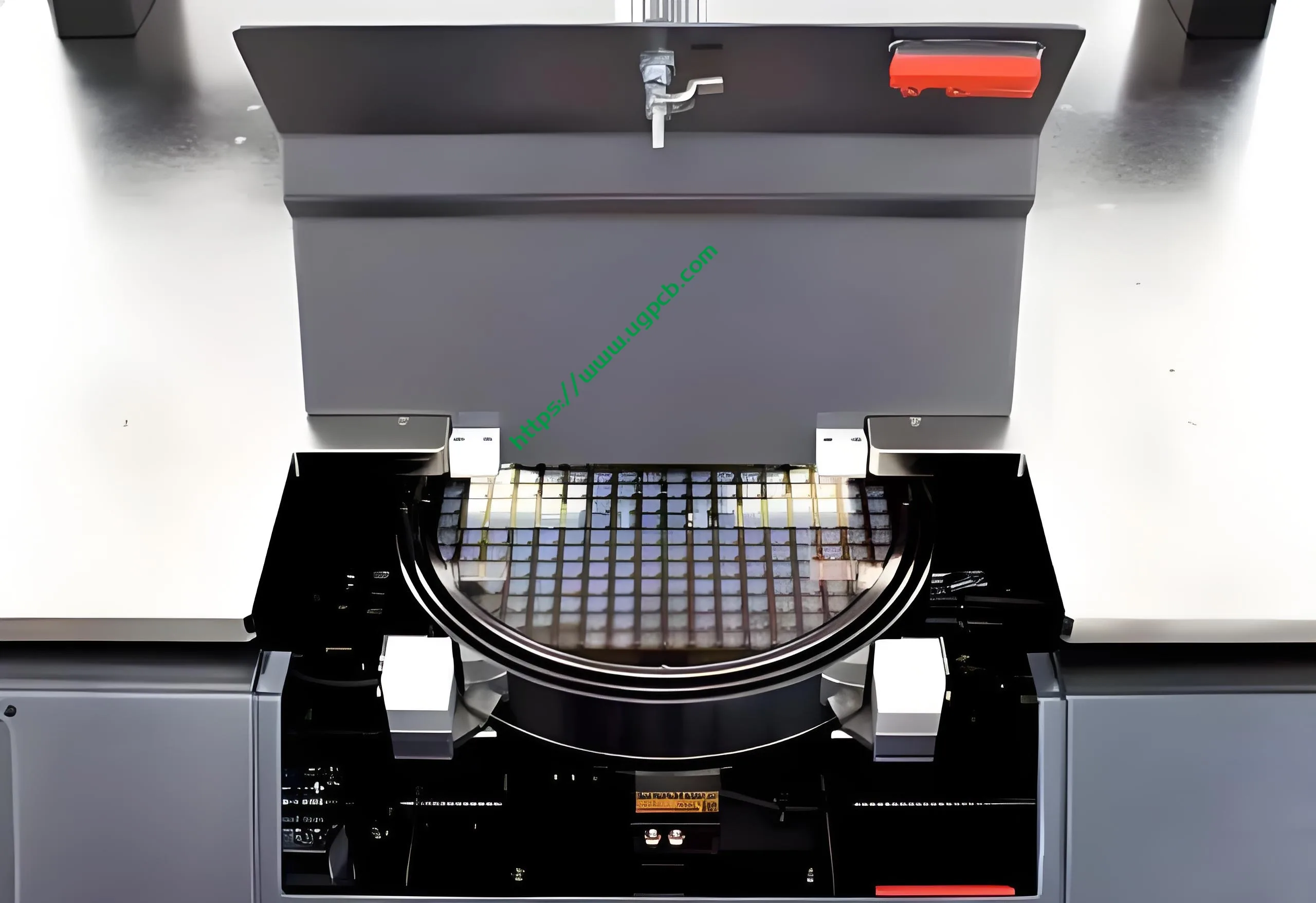

アプリケーションシナリオ

ATE test chip PCBs are primarily used in automated test equipment systems for the testing and validation of semiconductor chips. 半導体産業には欠かせないものです, where high-reliability testing is crucial for ensuring the quality and performance of chips before they are integrated into electronic devices. By utilizing ATE test chip PCBs, manufacturers can quickly and accurately identify any defects or issues in the chips, ensuring that only high-quality products are shipped to customers.

UGPCBのロゴ

UGPCBのロゴ