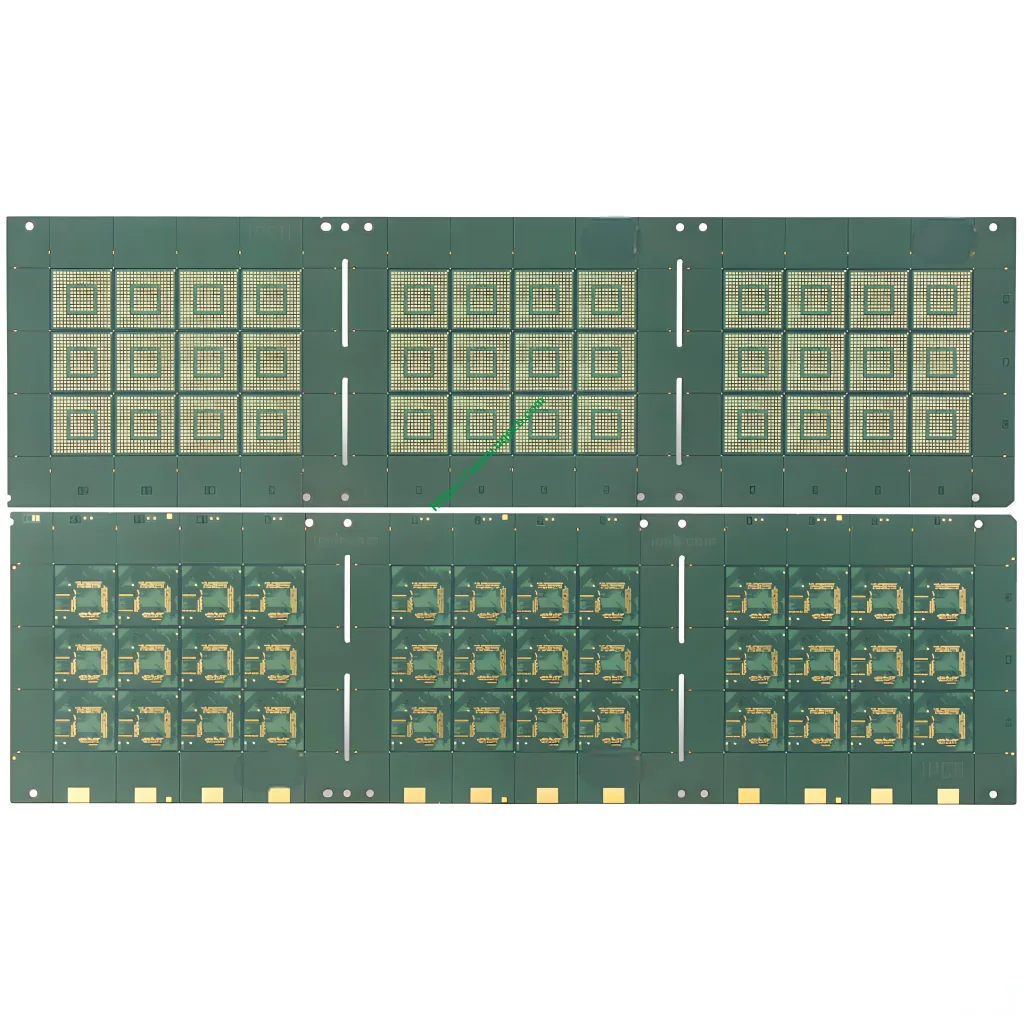

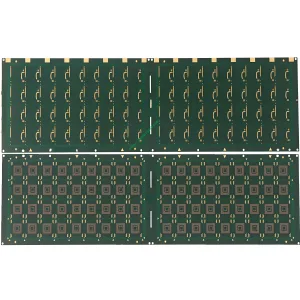

High-Performance BGA IC Substrate: The Precision Foundation for Advanced IC Packaging

In the era of smaller, もっと早く, and more powerful electronics, advanced IC packaging is critical. Acting as the essential interface between the silicon die and the main プリント基板 (プリント基板), の BGA IC基板 is the core component of high-end semiconductor packages. UGPCB leverages deep プリント基板の製造 expertise and advanced processes to deliver high-performance, 信頼性のある BGA package substrate ソリューション.

1. What is a BGA IC Substrate?

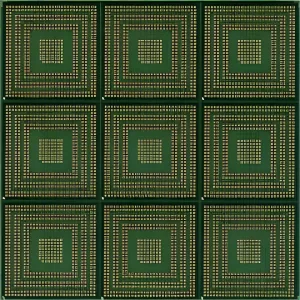

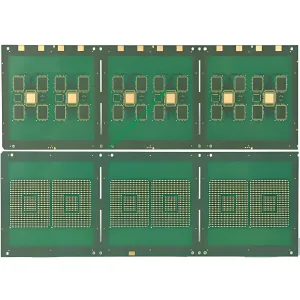

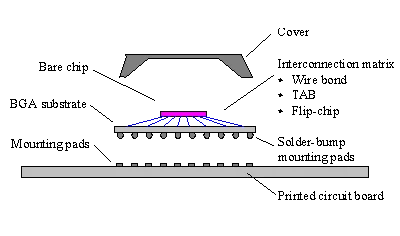

A BGA IC Substrate is a specialized type of 高密度相互接続 (HDI) プリント基板 designed explicitly for Ball Grid Array (BGA) 梱包. It is not a standard 回路基板 but a precision multilayer interconnect structure. One side interfaces with the die via ultra-fine circuitry, while the opposite side connects to the main PCBボード through an array of solder balls, fulfilling four key functions: electrical interconnection, 信号伝送, 熱放散, and physical support.

2. Design Essentials & Operational Principle

Design Essentials:

-

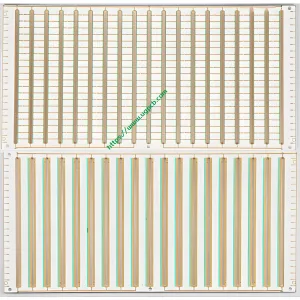

Ultra-High Wiring Density: To accommodate increasing I/O counts, substrates require ultra-fine line design. UGPCB reliably achieves 30μm/30μm minimum line width/space, enabling efficient fan-out routing for high-pin-count chips.

-

Precise Registration & 寸法安定性: Alignment between die and solder balls must be extremely accurate. Our core material, 三菱ガスHF BT HL832NX-A-HS, offers a low CTE (熱膨張係数) 優れた寸法安定性, preventing warpage and misalignment caused by thermal stress.

-

Reliable Microvias: Layer-to-layer interconnection depends on laser-drilled blind vias. 私たちの 0.075mm laser drilling capability facilitates high-density vertical connections (例えば。, 1-2, 3-4 レイヤー), ensuring signal integrity.

-

Optimized Signal & パワーの完全性: A carefully designed stack-up (例えば。, 1L-4L, 1L-2L, 3L-4L as per your specs) and plane allocation provide low-loss paths for high-speed signals and clean, stable power delivery to the chip.

Operational Principle:

The die is attached to the substrate’s top surface (typically Layer 1) via wire bonding or flip-chip technology. Electrical signals from the chip are routed, redistributed (RDL), and transmitted through the substrate’s internal ultra-fine traces そして マイクロバイアス (laser/mechanical holes). They finally exit via the solder ball array on the bottom surface to connect to the larger プリント基板 (PCB アセンブリ). It is essentially a miniaturized, chip-specific, high-end プリント基板.

3. コア素材, 構造 & 主な特長

-

コア素材: 三菱ガスHF BT HL832NX-A-HS high-performance laminate. Renowned for its 低い誘電率 (DK), low dissipation factor (Df), high thermal resistance (high Tg), and exceptional dimensional stability, it is the ideal choice for high-speed, high-frequency IC packaging substrates.

-

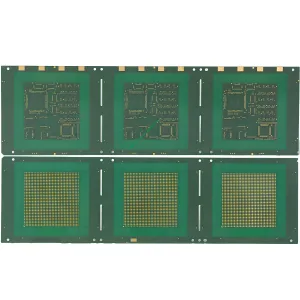

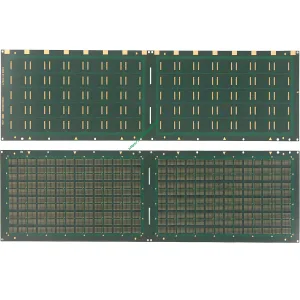

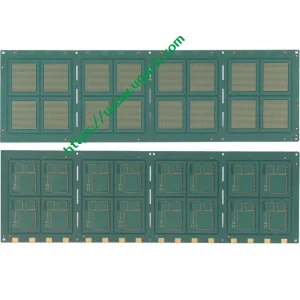

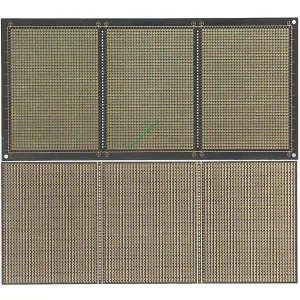

Key Structure: 4-layer build with stacked via design (1-2, 3-4 layer blind vias) for greater routing density. The overall PCB thickness is 0.3mm, meeting thin-profile packaging requirements.

-

表面仕上げ:****エネピック (エレクトロレスニッケルエレクトロレスパラジウムイマージョンゴールド, 2m”). This finish combines nickel’s barrier properties, palladium’s corrosion resistance, and gold’s superior solderability. It is the preferred choice for fine-pitch BGA solder ball アタッチメント, 長期信頼性の確保.

-

はんだマスク & Opening: We use タイヨー PSR4000 AUS308 high-performance Liquid Photoimageable Solder Mask (LPSM), known for high resolution and reliability, perfectly defining openings for 0.1mm mechanical through-holes and pads.

4. 分類 & 主要なアプリケーション

-

分類: Primarily categorized by interconnection method: Wire Bonding Substrates そして Flip Chip Substrates. The specifications provided (極細ライン, エネピック) are particularly suited for Flip Chip and other advanced packaging applications.

-

主要なアプリケーション:

-

Central Processing Units (CPU/GPU) 包装

-

Mobile Device Application Processors (AP) & Baseband Chips

-

High-Speed Networking & Communication Chips (例えば。, FPGA, ASIC)

-

人工知能 (ai) & Machine Learning Accelerators

-

Advanced Memory Packaging (例えば。, HBM)

-

These applications represent the core of 高密度, high-performance PCBA デザイン.

-

5. UGPCB’s BGA IC Substrate Production Process & 品質管理

私たちの BGA circuit board manufacturing follows a stringent, high-standard flow:

Inner Layer Imaging → Laser Drilling / Mechanical Drilling → Hole Metallization (Copper Plating) → Outer Layer Imaging → Solder Mask Application (PSR4000) → ENEPIG Surface Finish → Electrical Testing → Final Inspection.

The entire process occurs in controlled cleanroom environments (Class 10K/1K), utilizing Automated Optical Inspection (あおい), laser measurement systems, もっと, ensuring every BGA packaging PCB meets chip-level reliability standards.

6. Why Choose UGPCB for Your BGA IC Substrate?

-

Premium Material Assurance: Core laminates from top-tier suppliers like Mitsubishi Gas guarantee performance from the start.

-

Advanced Process Capability: 30/30μm line/space and 0.075mm laser microvias support the most cutting-edge chip packaging designs.

-

Ultra-Thin Core Expertise: Proven experience in high-yield, volume production of 0.3mm and thinner boards.

-

Comprehensive Surface Finish Options: We offer various high-end finishes including ENEPIG to meet different bonding/soldering needs.

-

One-Stop Service: から PCB design review そして クイックターンプロトタイプ to volume production, we provide end-to-end PCBA substrate solutions for your new chip project.

結論:

As we approach the physical limits of Moore’s Law, advanced packaging is key to continued electronics performance growth. Choosing a reliable BGA IC基板 lays a solid foundation for your chip’s success. Whether you are involved in chip design, 梱包, テスト, または PCBA製造, UGPCB is your trusted partner.

Contact us today to discuss your BGA package substrate, HDI PCB 要件, and request a quote. Let’s collaborate to enable the next generation of electronic innovation!

UGPCBのロゴ

UGPCBのロゴ