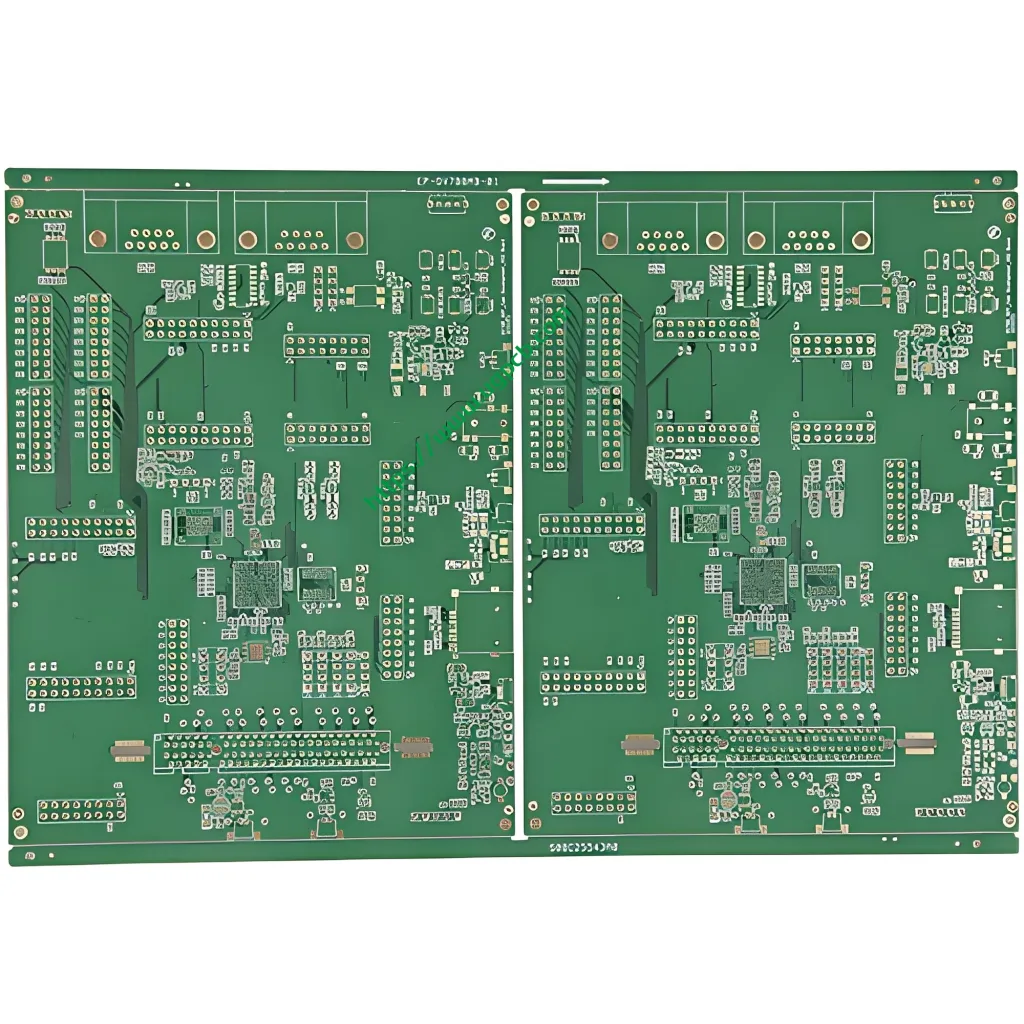

Definition of HDI PCB

High Density Interconnect (HDI) is simply a PCB with a higher number of interconnects in the smallest footprint. This leads to miniaturization of the circuit board. Components are placed closer together and board space is significantly reduced, but functionality is not compromised.

Characteristics of HDI PCB

More precisely, a PCB with an average of 120 に 160 pins per square inch is considered an HDI PCB. HDI designs combine dense component placement and versatile routing. HDI popularized microporous technology, creating denser circuits by implementing microvias, buried vias, and blind vias. Reduced drilling of copper is a feature of HDI designs.

Advantages of HDI PCB

Extraordinary Versatility

HDI boards are ideal when weight, 空間, 信頼性, and performance are the main concerns.

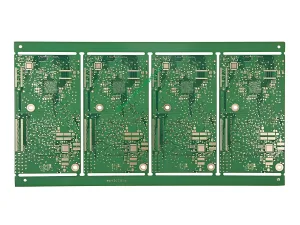

Compact Design

The combination of blind, buried, and micro vias reduces board space requirements.

Better Signal Integrity

HDI utilizes via-in-pad and blind via technology. This helps keep components close to each other, reducing signal path lengths. HDI technology removes through-hole stubs, thus reducing signal reflections, thereby improving signal quality. したがって, it significantly improves signal integrity due to shorter signal paths.

High Reliability

The implementation of stacked vias makes these boards a super barrier against extreme environmental conditions.

Cost-effective

The functionality of a standard 8-layer through-hole board (standard PCB) can be reduced to a 6-layer HDI board without compromising the quality. This makes HDI PCBs a cost-effective solution.

UGPCBのロゴ

UGPCBのロゴ