印刷回路基板アセンブリサービス

印刷回路基板アセンブリ(プリント基板) サービス: PCBファイル & bom plsはsales@ugpcb.comに送信します ( fast PCBA quote)

PCBAは、PCBコンポーネントとアセンブリだけでなく、PCB設計の知識を必要とするプロセスです, PCBの製造と最終製品の強力な理解. PCBAは、初めて完璧な製品を配信するためのパズルの1つにすぎません.

UGPCB assemble your PCBs with electronic components in SMT ( 表面マウント技術), 従来の波のはんだ付けプロセスで (ホールテクノロジーを通じて), 両方のプロセスの組み合わせで, 新しいTHRプロセス (穴のリフローを通して). すべてのはんだプロセスは、鉛のないはんだと鉛を含むはんだの両方で実行できます. 私たちはあなたのための完全な材料調達を喜んで世話します.

UGPCBoffer the following Printed circuit boards Assembly(プリント基板) サービス

A.キックターンプロトタイプアセンブリ,24-時間サーキットボードアセンブリサービス

B.Turn-Key Assembly,部分的なターンキーアセンブリ,委託会議

C.PARTSリスト準備とドキュメントサービス

D.UGPCBで相乗効果を購入することによるコスト効果のある材料調達

e.自動化された光学検査 (あおい) SMDアセンブリの

F.SMDファインピッチコンポーネントのアセンブリ (例えば. BGA, QFN, MF, マイクロスピードコネクタ)

G.水分に影響を受けやすいハンドリングコンポーネント (湿気に敏感なレベル≥ 3)

H.rohs準拠のリードフリーアセンブリ

i.Solderingプロセスは、リードのない、または鉛を含む

J.IPC-A610クラスに従って、アセンブリの生産とチェック 2

k. SMDアセンブリ機器

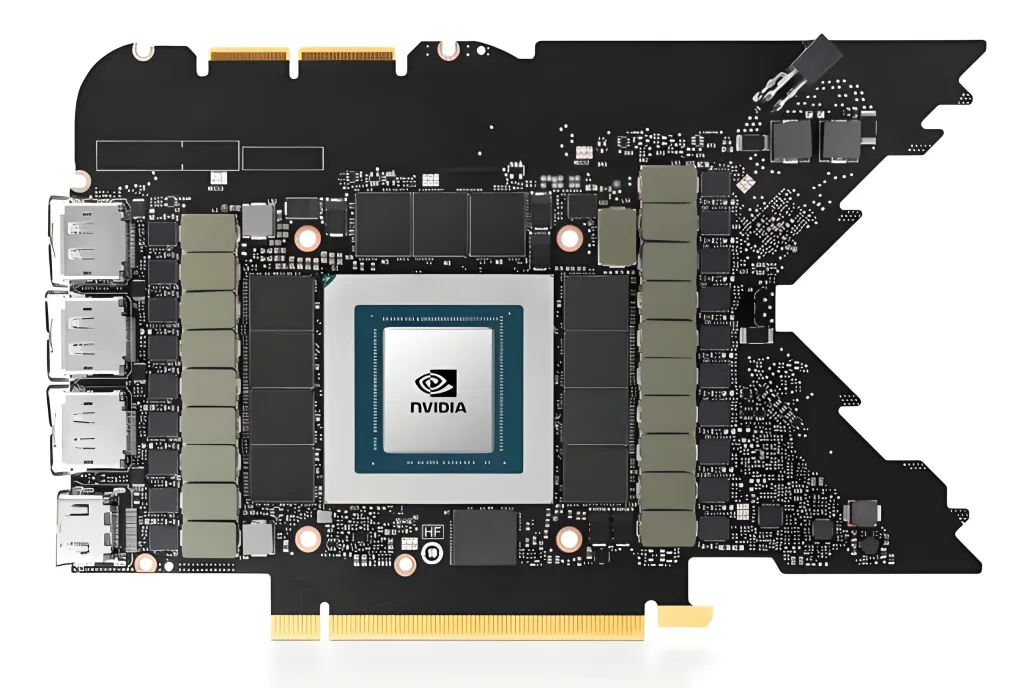

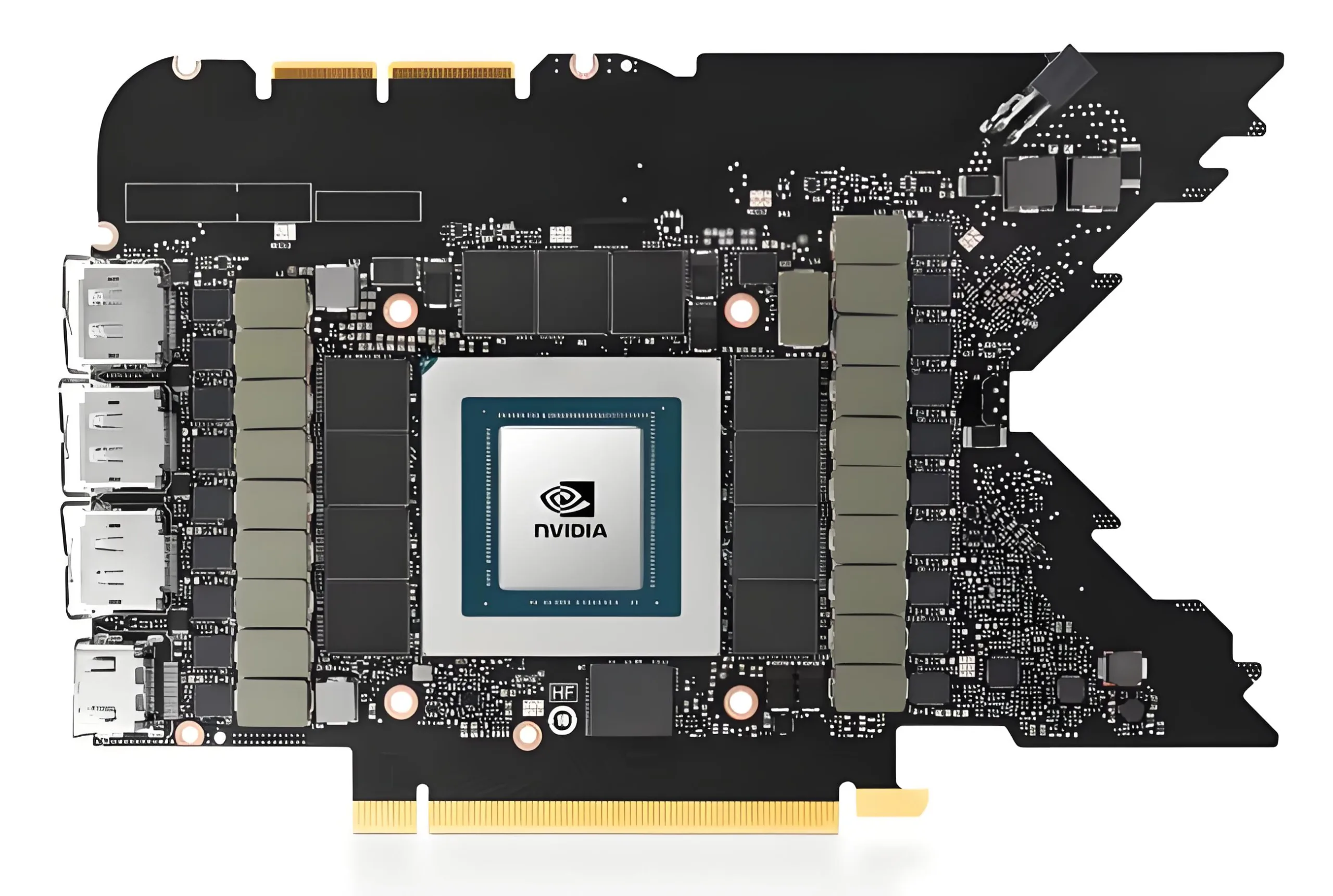

コンピュータグラフィックスPCBA

As the carrier of various components and the hub of circuit signal transmission, PCBA has become the most important and key part of electronic information products. Its quality and reliability level determine the quality and reliability of the whole equipment. Due to the development trend of high density PCB and the requirement of lead-free and halogen-free environmental protection, more and more PCBA appears poor wetting, explosion board, layered, layered, 等. CAF, 等. The acquisition of the failure mechanism and causes of PCBA will be beneficial to the quality control of PCBA in the future, thus avoiding the recurrence of similar problems.

UGPCB engineers and technicians have many years of experience in PCB/PCBA quality evaluation and failure analysis, and have accumulated a large number of practical cases, enabling customers to quickly solve problems and seize market opportunities.

UGPCBのロゴ

UGPCBのロゴ