導入

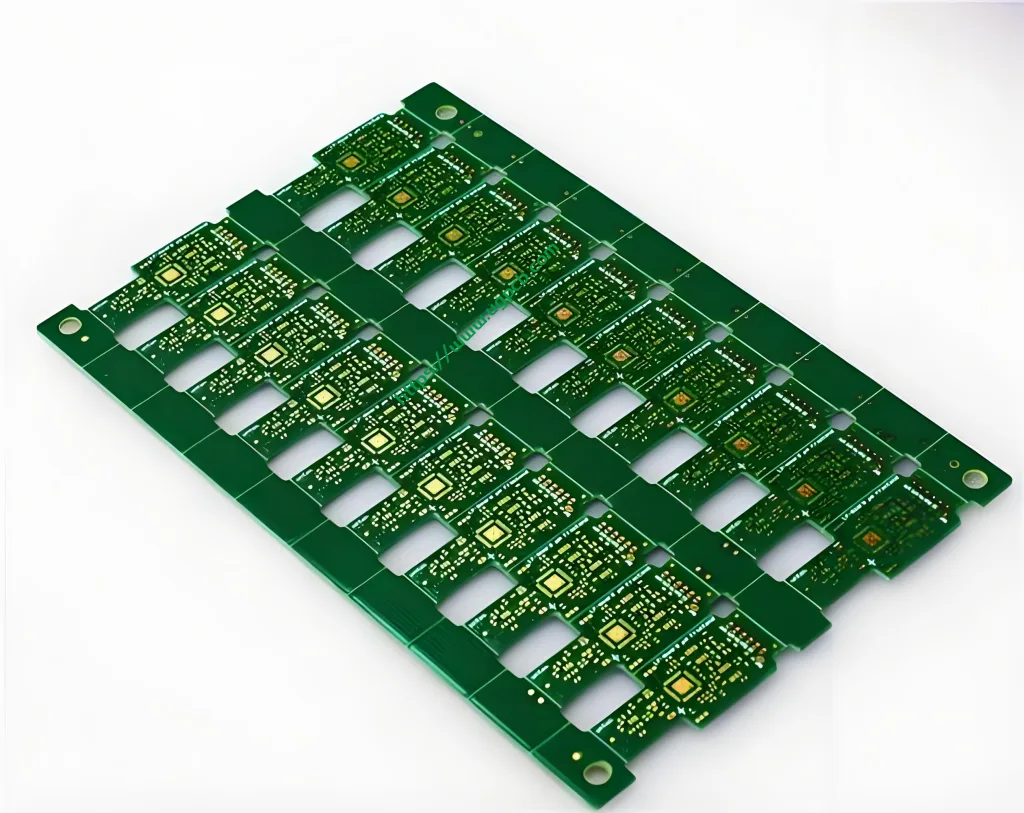

これは、大量生産ダブルサイドプリント回路基板です (プリント基板) それはUGPCBによって成熟します. 顧客に低コストのPCBを提供し、顧客を許可しています’ 市場を占有する製品.

両面PCBの種類

両面印刷回路基板 (プリント基板) 非常に重要なタイプのPCBです. 市場にはさまざまな種類の両面PCBがあります, 両面回路基板金属ベースPCBを含む, HI-TG重銅箔PCB, フラット巻き高周波両面PCB, 高周波プリント基板, ハイブリッド誘電ベース高周波両面PCB, 等. これらのPCBは、通信などの幅広いハイテク業界に適しています, 電源, コンピュータ, 産業用制御, デジタル製品, 科学的および教育機器, 医療機器, 自動車, 航空宇宙, 等.

構成と使用

両面印刷回路基板 (プリント基板) 通常、エポキシガラス布銅覆われたボードで作られています. 主に通信電子機器に使用されます, 高度な楽器, 高性能要件を持つ電子コンピューター.

製造工程

両面印刷回路基板の生産プロセス (プリント基板) 通常、プロセスワイヤメソッドに分割されます, ホールブロッキング方法, マスキング方法, およびパターンメッキエッチング方法. パターンメッキエッチング方法のプロセスフローが一般的に使用されます.

校正と仕上げプロセス

両面印刷回路基板 (プリント基板) 校正は一般に職人技を使用して行われます. さらに, ロジンプロセスなどのプロセス, OSPプロセス, 金メッキ加工, 浸漬金と銀のメッキプロセスも適用されます.

特定の仕上げプロセス

スプレースズプロセス: これは、シルバーホワイトパッドを添えて、簡単に缶とはんだの良い外観を提供します, そして、費用対効果が高い.

シッキムプロセス: これにより安定した品質が保証され、通常、ICの結合を含む場合に使用されます.

回路レイアウト

両面印刷回路基板の違い (プリント基板) 片面印刷回路基板 (プリント基板) 片面PCBの回路はPCBの片側のみにあるということです, 一方、両面PCBには両側に回路があります, 中央のVIAを介して接続されています.

生産パラメーター

両面印刷回路基板の生産 (プリント基板) 片面印刷回路基板のそれとは異なります (プリント基板). 生産プロセスに加えて, 追加の銅沈下プロセスがあります, これは、PCBの両側での回路伝導のプロセスです.

UGPCBのロゴ

UGPCBのロゴ