Importance of Double-Sided PCB Boards

Double-sided PCB board is a crucial type of circuit board widely used in various high-tech industries. It encompasses multiple types such as double-sided circuit board metal base PCB, Hi-Tg heavy copper foil circuit board, flat and winding double-sided circuit board, and high-frequency circuit board. These boards are suitable for applications in telecommunications, 電源, コンピュータ, 産業用制御, デジタル製品, 科学的および教育機器, 医療機器, 自動車, and aerospace defense.

UGPCB’s Commitment to Environmental Sustainability and Technological Innovation

UGPCB adheres to the environmental philosophy of reducing pollution, making good use of resources, and pursuing sustainable development. This commitment continuously enhances its industry position. UGPCB has independently developed a PCB automatic quotation online order platform, which realizes real-time PCB quotation, order placement, payment, and after-sales services. With a perfect Internet trading platform and the industry’s first automatic quotation system, customers can save waiting time, shorten the research and development cycle, and expedite product time-to-market.

UGPCB’s Dedication to Improving Production Processes and Technical Solutions

UGPCB strives to improve the production process of PCB, addressing technical challenges for customers, helping them win market share, and continuously tackling difficult technical issues. The company provides customers with more stable quality, higher performance products, and more satisfactory service.

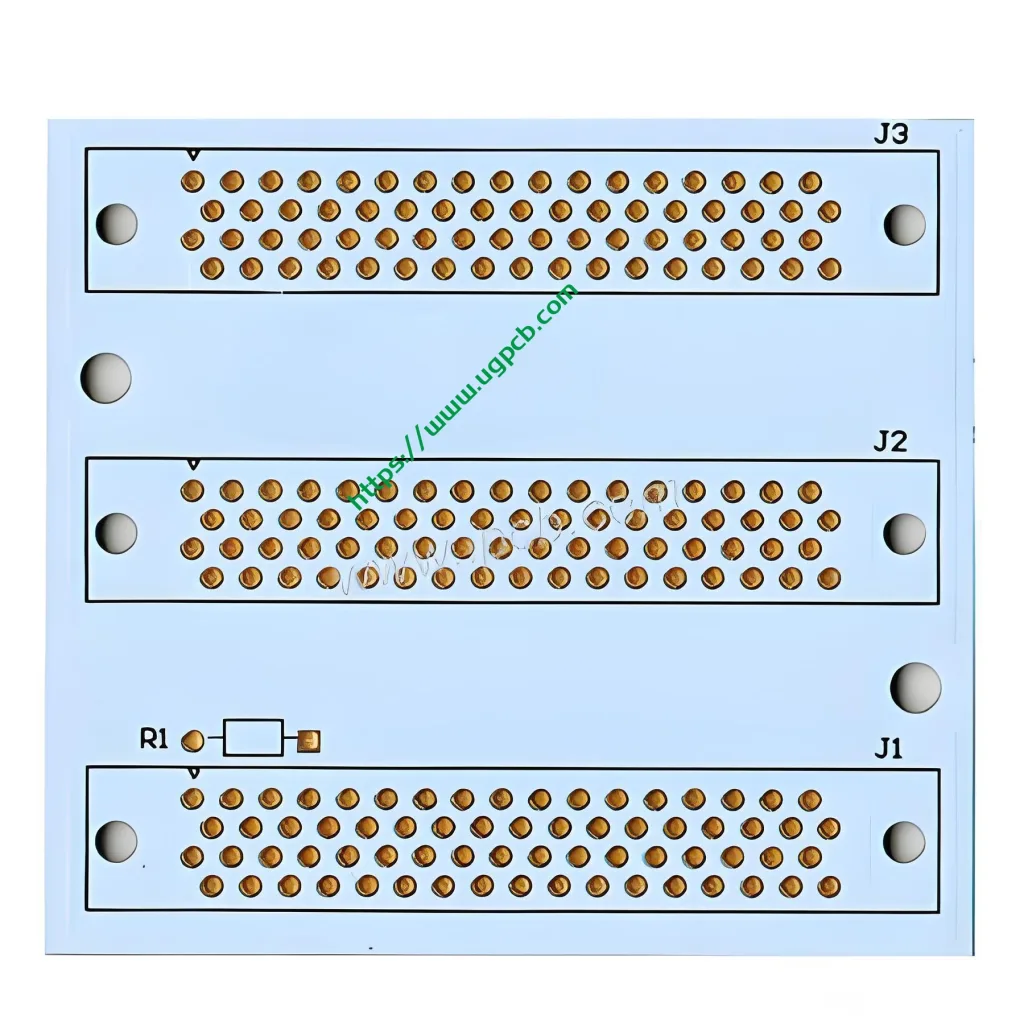

Composition and Applications of Double-Sided Printed Boards

Double-sided printed boards are typically made of epoxy glass cloth copper clad laminates, primarily used in communication electronic equipment, 高度な楽器, and high-performance electronic computers.

Production Processes of Double-Sided Panels

The production process of double-sided panels generally falls into several types, including the process wire method, hole plugging method, マスキング方法, およびパターンメッキエッチング方法. For double-sided PCB proofing, the most common process is the pattern plating-etching method. さらに, ロジンプロセスなどのプロセス, OSPプロセス, gold-plating process, 浸漬ゴールド, and silver-plating are applicable to double-sided boards.

Surface Finishing Processes

- Spray Tin Process: Offers good appearance, silver-white pads, easy tinning, easy soldering, and low cost.

- Sikkim Process: Known for stable quality, often used in IC bonding applications.

Differences Between Double-Sided and Single-Sided PCB Boards

The primary difference between a double-sided PCB board and a single-sided PCB board is that the single-sided PCB circuit is only on one side of the board, while the double-sided PCB circuit can be placed on both sides, with lines connected through vias. In addition to different production processes, double-sided PCB board production involves an extra copper sinking process, which facilitates double-sided circuit conductivity.

UGPCB’s Capability in Manufacturing Large-Volume Double-Sided PCBs

UGPCB is a manufacturer capable of stably producing large-volume double-sided PCBs, meeting the diverse needs of customers in various industries.

UGPCBのロゴ

UGPCBのロゴ