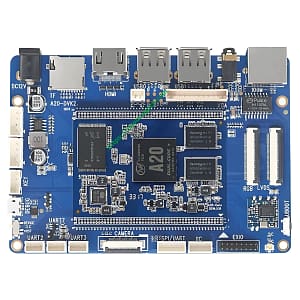

構造と構成

ベースプレートとレイヤーの構成

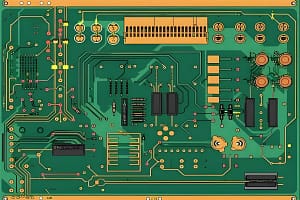

高周波ハイブリッドスプリントには、ベースプレートが含まれています, 折り畳まれ、最初の内側のワイヤレイヤーに配置されます, 最初の外側のワイヤ層, そして、はんだマスクインク層の上面は、上から上まで上部から下まで上部に向かって順に順番に. はんだ抵抗インク層の2番目の層も存在します.

基板部門

基板には、高周波エリアと補助領域が含まれます. 補助領域が最終的に固定されます, そして、高周波エリアのインレイは固定位置に配置する必要があります.

デザイン機能

エリア分割と材料の使用

ユーティリティモデルは、高周波ハイブリッドスプリントを提供します, 2つの部分に分かれています: 高周波エリアと補助エリア. 高周波エリアは独立して配置されており、高周波材料のみでできています. これにより、高周波ボード材料の使用が最小化され、生産コストが削減され、高周波信号要件が満たされます。.

機械的サポート

スプリントは、構造全体に機械的なサポートを提供します.

製品仕様

高周波ハイブリッド製品分類

- レイヤー: 6

- 使用済みボード: ロ4350b + FR4

- 厚さ: 1.6mm

- サイズ: 210mm*280mm

- 表面処理: 金メッキ

- 最小開口: 0.25mm

アプリケーションと機能

- 応用: コミュニケーション

- 特徴: 高周波混合圧力

UGPCBのロゴ

UGPCBのロゴ