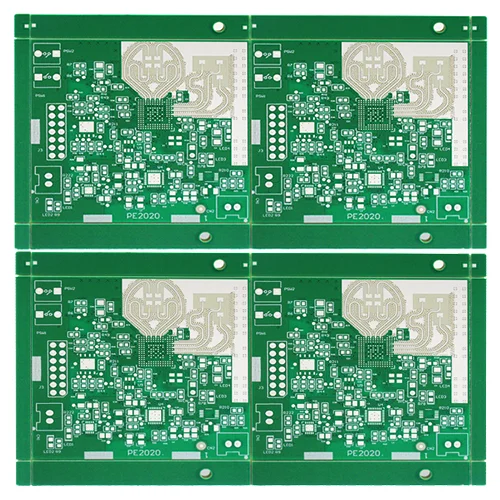

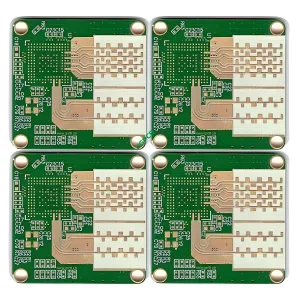

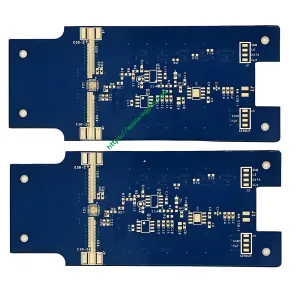

Hybrid PCB is commonly used in microwave RF series products

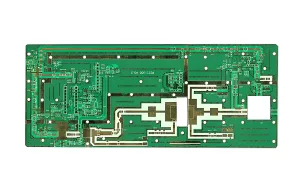

電子通信技術の急速な発展により, in order to achieve high-speed and high-fidelity signal transmission, more and more microwave radio frequency PCBs are used in communication equipment. 高周波ハイブリッド回路基板で使用される誘電体材料は、優れた電気特性と良好な化学的安定性を持っています, which are mainly manifested in the following four aspects.

1. Hybrid PCB has the characteristics of low signal transmission loss, 短い送信遅延時間, and low signal transmission distortion.

2. 優れた誘電特性 (主に低い相対誘電率Dkを指します, 低誘電損失因子DF). 加えて, 誘電特性 (DK, DF) remain stable under environmental changes such as frequency, humidity and temperature.

3. High-precision characteristic impedance control.

4. ハイブリッドPCBには優れた耐熱性があります (TG), processability and adaptability.

Microwave high-frequency hybrid PCBs are widely used in communication equipment such as wireless antennas, base station receiving antennas, パワーアンプ, レーダーシステム, navigation systems, 等.

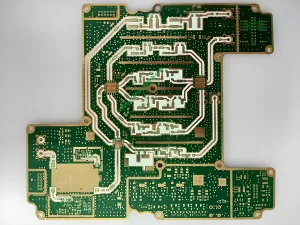

Based on one or more factors such as cost saving, improving bending strength and controlling electromagnetic interference, high-frequency lamination design must use high-frequency prepreg with low resin flow and FR-4 substrate with smooth dielectric surface. High-frequency composite laminate. この場合, there is a great risk of product adhesion control during the pressing process.

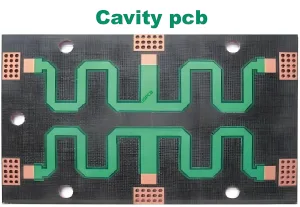

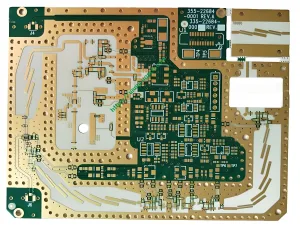

Microwave high-frequency hybrid PCB stacking method and characteristics

1. A high-frequency hybrid PCB controllable depth composite lamination structure, 高周波ハイブリッドPCBには、L1銅層が含まれています (高周波シート), L2銅層 (PPシート), L3銅層 (エポキシ樹脂基質), L4 copper layer in sequence; L2, L3, L4 copper layers are provided with slots of the same size at the same position; L4 copper layer is arranged with three-in-one buffer material from inside to outside, and steel plate and kraft paper are stacked from outside to outside in sequence; aluminum plate, steel plate, and kraft paper are stacked on L1 copper layer from inside to outside.

2. According to the first feature, the three-in-one buffer material is a buffer material sandwiched between two layers of release film.

3. According to the first feature, the laminated structure of the high-frequency board controlled deep hybrid board of the present invention is characterized in that the high-frequency sheet is a polytetrafluoroethylene board.

The expansion and contraction characteristics of the high-frequency hybrid PCB composite board are different from those of the ordinary epoxy resin substrate, so the warping and shrinkage of the board are difficult to control, and the processing method of first grooving and then pressing will cause the problem of metal dents on the board. The three-in-one buffer material is set on one side of the groove, and the buffer material can be filled into the groove hole during pressing to avoid the problem of dents. Kraft paper buffer pressure is set on both sides of the cardboard to balance the heat transfer uniformly, and the steel plate is set to ensure uniform heat conduction during pressing, so that the pressing is flat, and the heat and pressure during the pressing process are balanced, so as to better control the curvature and expansion of the board.

5G通信技術の急速な発展により, higher frequency requirements are put forward for communication equipment. There are many microwave high-frequency hybrid PCBs on the market. これらのマイクロ波の高周波ハイブリッドPCBの製造技術も、より高い要件を提起しています. We have been specialized in UGPCB processing for more than 10 years and can provide multi-layer hybrid PCB manufacturing services. We have all the equipment required for the entire process of multi-layer hybrid PCB production, comply with the ISO9001-2000 international standard management system, and have passed the iatf16949 and ISO 14001 システム認証. Our products have passed UL certification and comply with IPC-A-600G and IPC-6012A standards. We can provide high-quality, high-stability, and high-adaptability microwave high-frequency hybrid PCB samples and batch services.

UGPCBのロゴ

UGPCBのロゴ