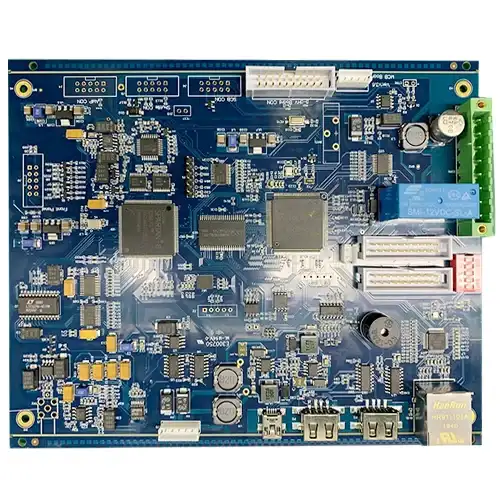

Printed Circuit BoardAssembly Services

Printed circuit boards Assembly(プリント基板) Services: PCB File & BOM Pls send to Sales@UGPCB.com ( fast quote)

PCBA is a process that requires knowledge not just of PCB components and assembly but also of PCB design, PCB fabrication and a strong understanding of the final product. PCBA is just one piece of the puzzle to delivering the perfect product the first time.

UGPCB assemble your PCBs with electronic components in SMT ( surface mount technology), in the conventional THT wave soldering process (through hole technology), in a combination of both processes, the new THR process (through hole reflow). All soldering processes can be performed with both lead-free solders and solders containing lead. We would be happy to take care of the complete material procurement for you.

UGPCB offer the following PCB Assembly (プリント基板) Services:

a.Quick-turn prototype assembly,24-hour circuit board assembly service

b.Turn-key assembly,Partial turn-key assembly,Consignment assembly

c.Parts list preparation and documentation service

d.Cost-effective material procurement by means of purchasing synergies in the UGPCB

e.Automated optical inspection (あおい) of SMD assemblies

f.SMD assembly of fine-pitch components (e.g. BGA, QFN, QFP, MicroSpeed connector)

g.Handling components susceptible to moisture (moisture sensitive level ≥ 3)

h.RoHS compliant lead-free assembly

i.Soldering processes free of or containing lead

j.Production and check of the assemblies as per IPC-A610 class 2

k. SMD Assembly Equipments

UGPCBのロゴ

UGPCBのロゴ