材料構成

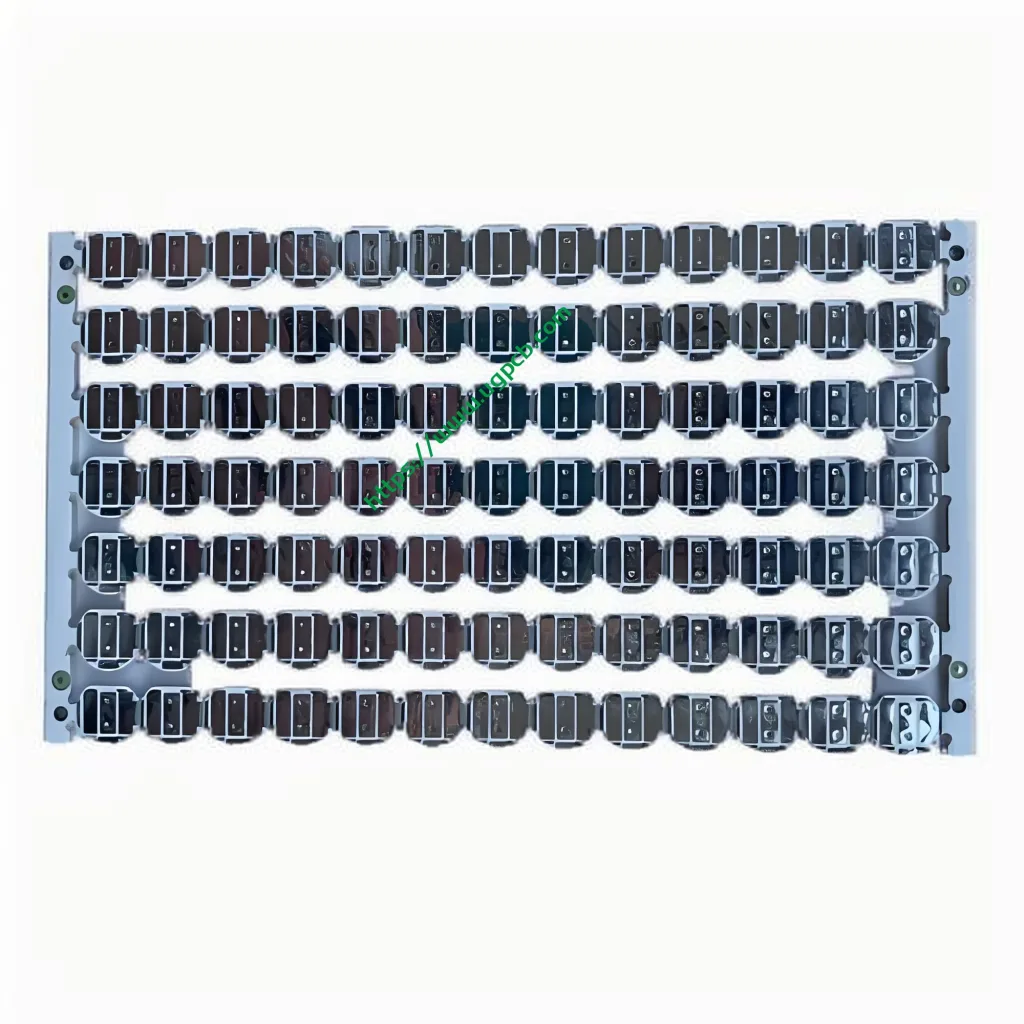

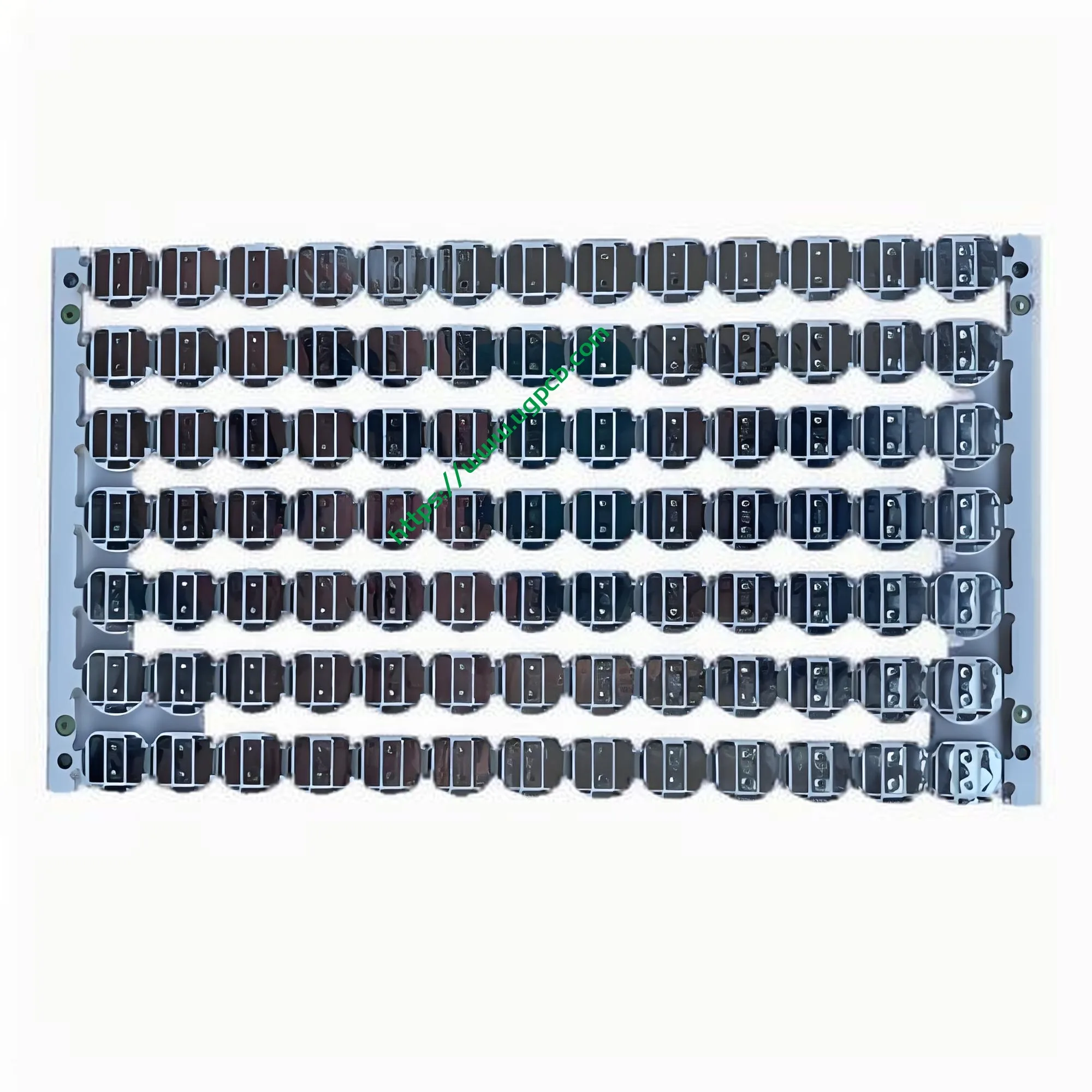

The 6061 Aluminum Based PCB for automobile LED lamp is constructed with a 6061 aluminum base. 6061 aluminum is a versatile alloy known for its high corrosion resistance, 良好な機械加工性, and excellent strength-to-weight ratio. This material choice makes the PCB lightweight yet durable, ideal for automotive applications.

Performance and Characteristics

- Layer Structure: The PCB features a single-layer design, simplifying the manufacturing process and reducing costs while still providing effective electrical connections.

- カラーオプション: Available in white or black, the PCB can blend seamlessly into the interior or exterior design of an automobile.

- 仕上がり厚さ: With a thickness of 1.0mm, the PCB offers a sturdy base for mounting LED components and ensuring reliable electrical connections.

- 銅の厚さ: The copper thickness of 1OZ provides sufficient electrical conductivity and current carrying capacity for LED lighting applications.

- 表面処理: The lead-free HASL (Hot Air Solder Leveling) surface treatment ensures good solderability and corrosion resistance, making the PCB compatible with modern manufacturing processes.

- 熱伝導率: The PCB boasts a thermal conductivity of 2.0w/m.k, effectively dissipating heat generated by LED components, thus prolonging the lifespan of the lighting system.

Unique Features

- Excellent Thermal Management: The high thermal conductivity of the 6061 aluminum base allows for efficient heat dissipation, preventing overheating and ensuring optimal performance of the LED lamp.

- Lightweight and Durable: The combination of aluminum and copper makes the PCB both lightweight and durable, suitable for use in automotive environments where vibration and temperature fluctuations are common.

製造工程

The production of the 6061 Aluminum Based PCB for automobile LED lamp involves several steps:

- 材料の準備: High-quality 6061 aluminum sheets are selected and prepared for PCB manufacturing.

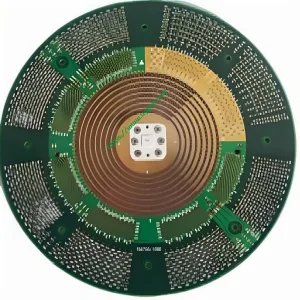

- 回路パターニング: Using photolithography and etching techniques, the desired circuit patterns are etched onto the copper layer adhered to the aluminum base.

- 穴あけ加工とメッキ加工: Precision drilling creates vias for interconnections, and the holes are plated with copper to ensure electrical conductivity.

- 表面仕上げ: The PCB undergoes lead-free HASL surface treatment to enhance solderability and corrosion resistance.

- 品質管理: Rigorous testing and quality control measures are implemented to ensure the PCB meets all specifications and standards for automotive applications.

アプリケーションシナリオ

The 6061 Aluminum Based PCB for automobile LED lamp is specifically designed for use in automobile LED lighting systems. Its excellent thermal management capabilities, lightweight design, and durability make it suitable for a variety of automotive applications, 含む:

- Headlights: The PCB can support high-brightness LED headlights, providing enhanced visibility and safety for drivers.

- Taillights: The PCB’s compact design and efficient heat dissipation make it ideal for use in taillights, ensuring reliable operation and longevity.

- Interior Lighting: The PCB can be used in interior lighting applications, such as dome lights and map lights, providing a sleek and modern appearance.

- Signal Lights: The PCB’s high thermal conductivity and durability make it suitable for use in signal lights, such as turn signals and brake lights, ensuring clear and consistent signaling.

要約すれば, の 6061 Aluminum Based PCB for automobile LED lamp offers exceptional performance, 信頼性, and versatility, making it an ideal choice for automotive lighting applications.

UGPCBのロゴ

UGPCBのロゴ