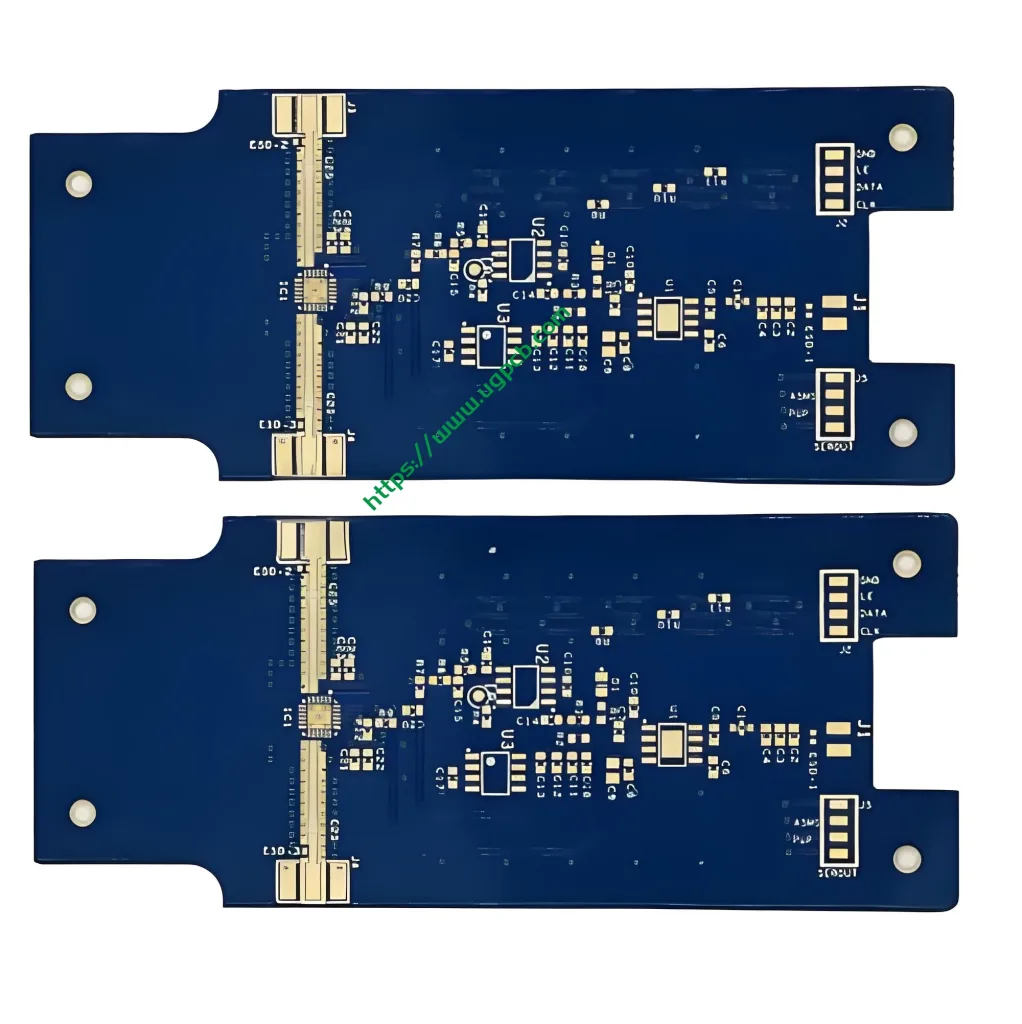

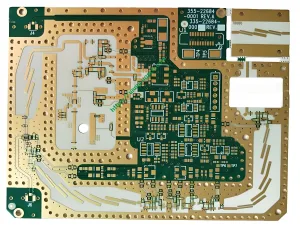

Teflon PCBの概要

テフロン基板, 高周波アプリケーションでの並外れたパフォーマンスで知られています, 印刷回路基板の一種です (プリント基板) テフロンラミネート材料を利用します. この材料は、その優れた誘電特性のために選択されています, マイクロ波と高頻度の電子デバイスに最適です. テフロンPCBの品質は通常、IPC6012クラスIIまたはクラスIII標準に準拠しています, 信頼できる一貫したパフォーマンスを確保します.

定義と重要な仕様

テフロンPCBは、誘電材料としてテフロンを使用することによって定義されます, 誘電率の範囲を提供します 2.0 に 3.5. これらのボードは、範囲のレイヤーカウントで製造できます 2 に 34 レイヤー, 回路設計におけるさまざまな複雑さに柔軟性を提供します. テフロンPCBの厚さは0.1mmから12mmまで変化する可能性があります, さまざまなアプリケーションのニーズに応えます. 銅の厚さは通常0.5ozのベースで始まり、1ozまで完成できます, 高周波信号に適切な導電率を確保します.

設計上の考慮事項

Teflon PCBSを設計するとき, いくつかの重要な要因を考慮する必要があります:

- 誘電率 (DK) および散逸係数 (Df): 材料には、信号の完全性を確保し、高周波数での損失を最小限に抑えるために、正確なDKおよびDF値が必要です.

- 層の数と厚さ: 回路の複雑さに応じて, 指定された範囲内で層の数と全体の厚さを調整できます.

- 銅の厚さ: 低インピーダンスを維持し、信号損失を減らすためには、適切な銅の厚さが重要です.

- 表面技術: Immersion GoldやISIGなどのオプション (浸漬シルバー) 表面仕上げに利用できます, それぞれが導電性と信頼性の観点から異なる利点を提供する.

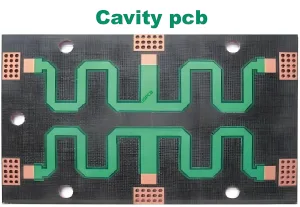

作業原則

Teflon PCBSは、制御されたインピーダンスと最小限の信号損失の原理に基づいて動作します, これは、高周波アプリケーションに不可欠です. テフロン材料の低い誘電率は、位相遅延と減衰を減らすことにより、信号の完全性を維持するのに役立ちます. これにより、Teflon PCBSはマイクロ波とRFに特に適しています (無線周波数) 信号純度が重要なアプリケーション.

アプリケーション

Teflon PCBSの主要なアプリケーションは、マイクロ波と高頻度の電子機器の分野にあります. レーダーシステムなどのデバイスで使用されます, 衛星通信, そして、高性能と信頼性が最も重要な他のRFコンポーネント. 最小限の損失で高周波数を処理する能力により、Teflon PCBSはこれらの厳しいアプリケーションに最適です.

分類

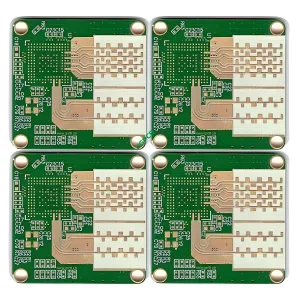

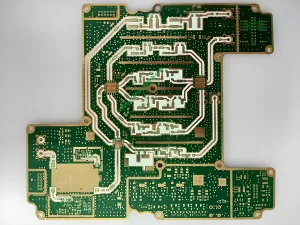

Teflon PCBSは、レイヤーカウントに基づいて分類できます, 厚さ, および特定のアプリケーション. 一般的な分類には含まれます:

- 片面および両面ボード: より少ないレイヤーのより簡単なアプリケーションの場合.

- マルチレイヤーボード: 相互接続の複数の層を必要とするより複雑な回路の場合.

- 高周波固有ボード: マイクロ波およびRFアプリケーション専用に設計されています, 多くの場合、材料特性と製造精度に関する厳しい要件があります.

材料特性

テフロンのユニークな特性は、高頻度のPCBに理想的な材料になります:

- 低誘電率: 信号の遅延と損失を減らすのに役立ちます.

- 温度範囲全体で安定した性能: さまざまな環境条件で一貫したパフォーマンスを保証します.

- 水分吸収に対する高い耐性: 湿気の浸入による信号の品質の分解を防ぎます.

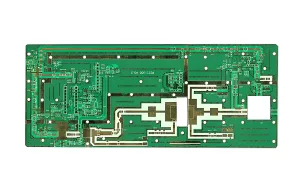

製造工程

Teflon PCBの生産には、いくつかのステップが含まれます:

- 材料の選択: 必要なDKおよびDF値に基づいて適切なテフロン材料を選択する.

- 回路設計: 高周波性能を考慮して回路レイアウトを作成します.

- エッチング: 不要な銅を除去して、目的の回路パターンを作成します.

- ラミネート加工: 高圧と温度の下で複数の層を結合します.

- 表面仕上げ: 選択した表面技術を適用します, Immersion GoldやISIGなど.

- テストと品質管理: 最終製品がすべての仕様と標準を満たすようにします.

シナリオを使用します

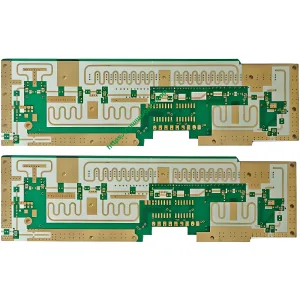

テフロンPCBは、高周波性能が重要なシナリオで使用されます, のような:

- マイクロ波アンテナ: 効率的な信号伝送と受信用.

- 衛星通信: 地球と空間の間の信頼できるデータ転送を確保します.

- レーダーシステム: 正確で安定した信号処理機能を提供します.

結論は, Teflon PCBSは、高周波アプリケーション向けに設計された特殊な回路基板です, 優れた誘電特性と信号の完全性を提供します. 彼らのデザイン, 材料, および生産プロセスは、マイクロ波とRFテクノロジーの厳しい要件を満たすように調整されています.

UGPCBのロゴ

UGPCBのロゴ