PCB材料は主に電子回路およびマイクロ波回路で使用されます. そのパフォーマンスは信号伝送速度に重要な影響を与えます, 回路システムのエネルギー損失と特性インピーダンス. RT/デュロイド 6006 and 6010.2LM is a high performance microwave PCB material introduced by Rogers Corporation, a well-known material supplier. Its material type is ceramic-polytetrafluoroethylene (PTFE) composite with dielectric constant of 6.15, which is mainly for high-frequency circuit applications.

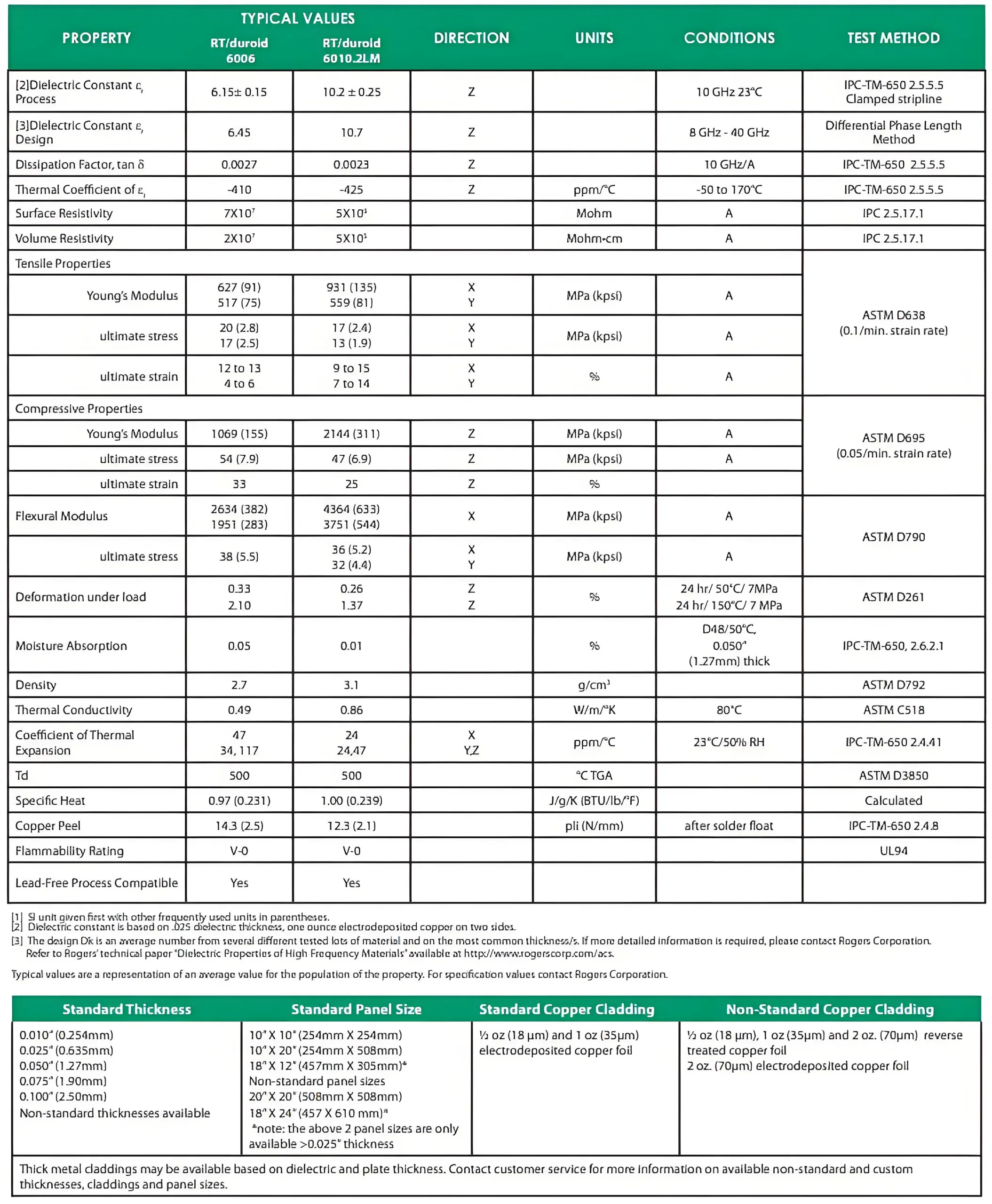

ロジャース PCB RT/デュロイド 6006 and 6010.2LM PCB Substrate Parameter Table

RT/デュロイド 6006 has strictly controlled dielectric constant, 厚さ, low hygroscopicity and excellent thermomechanical stability. It has a simple manufacturing process and can maintain high stability in long-term use. Users can specify the thickness of PCB material and the weight of copper foil when ordering RT/duroid 6006. Rogers provides two-sided thickness from 1/2 オンス. に 2 オンス. /ft2 (18 に 70) for RT/duroid 6006 microwave PCB materials μ M) Standard or reverse-treated electroplated copper clad, with thick aluminium, brass or copper based metal sheets available for customization. RT/デュロイド 6006 contains the following standard tolerance media thickness: 0.010, 0.025, 0.050, 0.075″and 0.100″ (0.254, 0.635, 1.270, 1.905, 2.54 mm).

RT/デュロイド 6006 microwave PCB material can be used in the following fields: patch antenna, satellite communication system, パワーアンプ, aircraft anti-collision system, ground-based radar early warning system.

Features and advantages of RT/duroid 6006:

A dielectric constant of up to 6.15 helps reduce circuit size

Ideal for low loss, X band and below

Strictly controlled thickness and dielectric constant tolerances for circuits requiring high repeatability

Product specifications for RT/duroid 6006:

Standard thickness, 0.005 (0.127 mm), 0.010 (0.254 mm), 0.025 (0.635 mm), 0.050 (1.27 mm), 0.075 (1.90 mm), 0.100 (2.50 mm)

Standard panel dimensions for RT/duroid 6006:

10″X 10″ (254 X 254 mm), 10 “X 20” (254 X 508 mm), 20 “X 20” (508 X 508 mm) – Nonstandard, 18 “X 12” (457 X 305 mm), 18 “X 24” (457 X 610 mm) – Nonstandard

Standard copper clad thickness for RT/duroid 6006

1/2 オンス. (18) μ M), 1 オンス. (35) μ M), 2 オンス. (70) μ M)

Model of RT/duroid 6006 and 6010.2LM:

RT/デュロイド 6006 PTFE Ceramic, RT/デュロイド 6000, 6006 10X20 2E/2E 0100+-001/DI, 6010.2LM 10X10 HH/HH 0250+-001/DI, 6010.2LM 20X20 HH/HH 0250+-001/DI, 6010.2LM 20X20 1E/063AL 0250+-001/DI, 6010.2LM 20X20 H1/063AL 0100+-001/DI, 6010.2LM 10X10 2E/150AL 0250+-001/DI, 6010.2LM 10X10 H2/H2 02/00+- DI, 6010.2LM 10X10 5E/5E 0100+-001/DI, 6010.2LM 10X20 H1/200AL 0250+-001/DI, 6010.2LM 10X10 H1/H1 0100+-001/DI, RT/duroid 6010.2LMPTFE ceramic, 6010.2LM 10X10 HH/HH 0400+-0015/DI, 6010.2LM 20X20 HH/200ALTT 0250+-001/DI, RT/duroid 6010.2LMNSPTFE+Ceramic, 6010.2LMNS 20X20 HH/HH 0050+-0005/DI

Category of RT / Duroid 6006

microwave circuit board and high frequency laminate

Application of RT / Duroid 6006:

Locomotive, 鉄道輸送, electric power, renewable energy, body and chassis, lighting, equipment and inverter power supply, national defense industrial equipment, on-board, on-board communication, on-board entertainment, Internet of vehicles, industrial automation, industrial servo, indoor lighting, smart home, industrial equipment control, mobile phone related, electric vehicle power system, 通信機器, Internet of things, storage, safety system, patch antenna, satellite communication system, パワーアンプ, aircraft anti-collision system, Ground radar early warning system,

The two dielectric constants of RT/duroid 6006 are manufacturing process (6.15) and design (6.45). Design dielectric constant 6.45 is chosen for circuit simulation.

If the dielectric constant of the bonded sheet is required, it is recommended to use RO3006 bonded sheet with a minimum thickness of 5 ミル (0.127 mm). If there is no requirement for the dielectric constant of the bonded sheet, it has a thickness of 1.5mil (0.038mm), のような 2929.

Rogers RT/duroid high-frequency circuit materials are composite PCB materials of PTFE (including randomly filled glass or ceramic) suitable for high-reliability applications such as aerospace. The RT/duroid family has long been the industry’s most reliable high-reliability PCB material.

The advantages of RT/Duroid PCB material, with ultra-low loss, 吸湿性が低い, stable dielectric constant (DK) with frequency, low outgassing, suitable for aerospace applications, antenna systems and communication systems.

RT Duroid PCB materials products include

ロジャース PCB RT/デュロイド 6006 and 6010.2LM PCB substrates

RT/デュロイド 5870, DK 2.33, Df: .0012@10GHz

RT/デュロイド 5880, DK 2.20, Df: .0009@10GHz

RT/duroid 5880LZ, DK 2.0, with unique filler to reduce material weight

RT/デュロイド 6002, DK 2.94, with excellent electrical and mechanical properties for complex microwave structures

RT/デュロイド 6006 and 6010.2LM, DK 6.15 または 10.2, tight thickness control ensures size reduction

RT/duroid 6035HTC, DK 3.6, thermal conductivity of 1.44 W/m/K, 2.4 times that of standard RT/duroid products

RT/デュロイド 6202, DK 2.90, reinforced with glass cloth for excellent dimensional stability

RT/duroid® 6202PR, low Dk of 2.90 または 2.98, reliable mechanical properties and excellent electrical properties for planar resistor applications

The antenna gain is related to the dielectric loss and copper foil loss of the RT/duroid 6010 PCB material. An increase in both losses will reduce the gain index of the entire antenna. Due to the high frequency, copper foil loss plays a dominant role. 例えば, there are scratches and stains on the copper foil surface and the dielectric surface, so the scratches on the antenna transmission microstrip line and the dielectric stain at the port will increase the loss and reduce the gain. These are mainly related to the PCB processing process.

RT/デュロイド 6010 PCB material is polytetrafluoroethylene with a small amount of ceramic powder added, and the texture is relatively soft. If the surface dielectric and copper foil are damaged, it is equivalent to increasing the loss of the dielectric and copper foil, which will reduce the antenna gain. In order to improve the antenna yield, the PCB processing process must prohibit any mechanical grinding or friction on the PTFE dielectric surface after copper foil etching to protect the roughness of the dielectric surface after etching. After processing, chemical cleaning is required to ensure that the surface is free of stains. Confirm PCB processing During the process, attention should be paid to protecting the surface roughness of the copper foil and the surface of the dielectric to improve the antenna yield.

ロジャース’ 6010 series of high-frequency PCB materials used to have three models, 6010.2LM, 6010.5LM and 6010.8LM, but the latter two have been discontinued one after another, and 6010.2LM is now recommended.

UGPCBのロゴ

UGPCBのロゴ