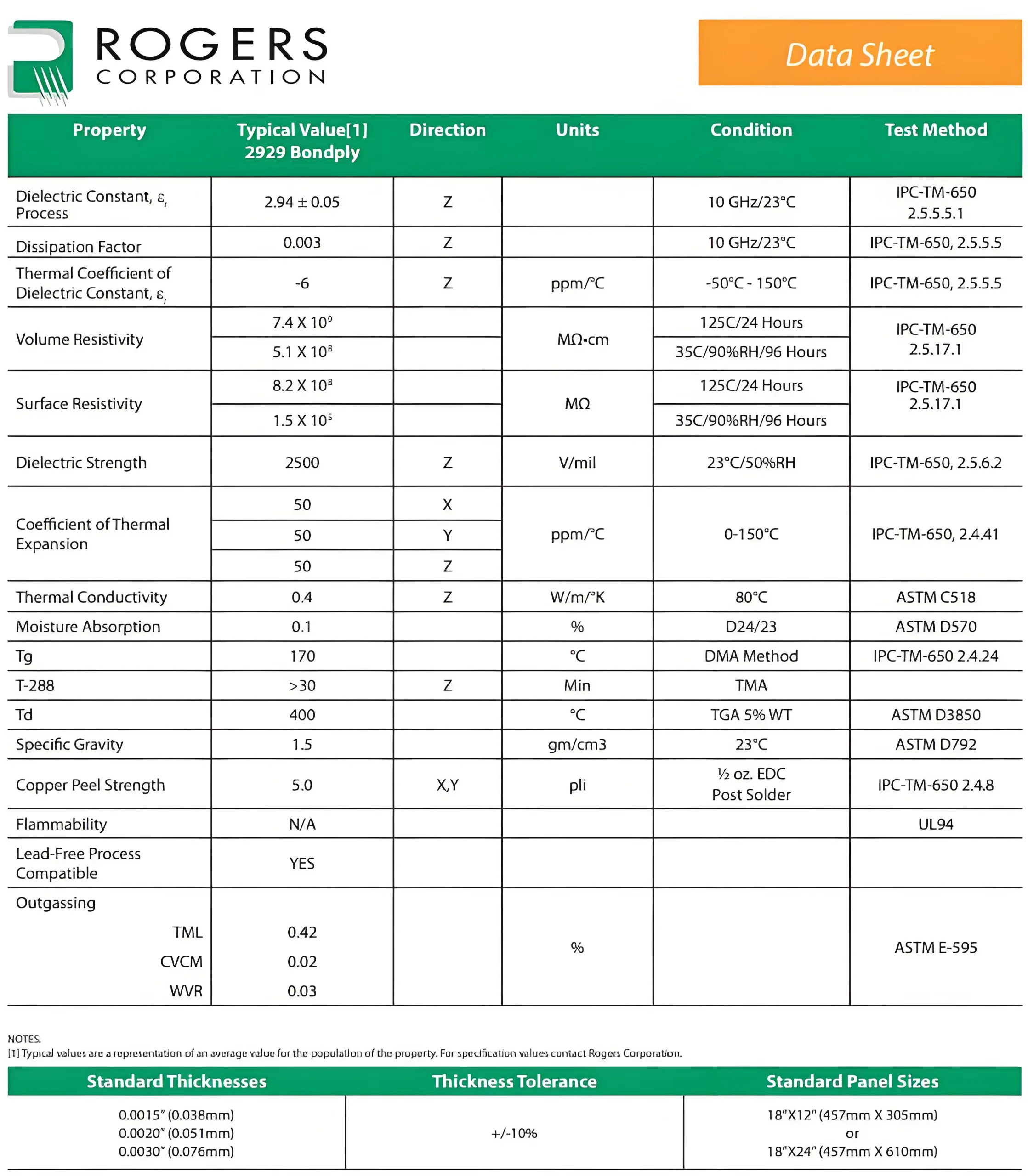

Rogers prepreg 2929 has a hydrocarbon base material without glass fiber reinforcement inside and is a thermoset material. ロジャース 2929 Bond Sheet has a coefficient of thermal expansion of 50ppm/oC in the 0-150 degree range. Under D24/23 conditions, its moisture absorption rate is 0.1%.

ロジャース 2929 シリーズPCB基板

ロジャース 2929 ボンドプライは非強化です, 高性能を実現する炭化水素ベースの薄膜接着システム, 高信頼性多層構造. 低誘電率 (2.9) と損失正接 (<0.003) at microwave frequencies make it ideal for bonding multi-layer boards (MLBs) made with PTFE composites such as RT/duroid6000 and RO3000 series laminates, filled water carbon resin composites such as RO4000 core and special thin core laminates. A proprietary cross-linked resin system makes this thin-film adhesive system compatible with sequential bonding processes, while the controlled flow characteristics provide excellent blind-through fill capability and potential for designs requiring blind vias and/or buried cavities. Predictable reduction rate. 2929 bondply is compatible with traditional flat press and autoclave bonding.

The film is currently available in 0.0015 inch, 0.002 inch, そして 0.003 inch thick sheets. Individual sheets can be stacked to create a thicker bond layer. The unreinforced film can be bonded to the inner layer to facilitate simultaneous processing of cuts through the core and adhesive layers and to facilitate the use of the conductive paste to form vias. The easy-to-release carrier film protects the adhesive layer from contamination during processing, conductive paste screening, and MLB booking.

ロジャース 2929

What is the difference between Rogers 2929 membrane and 4450T?

RO4450T prepreg is also a ceramic-filled, low-loss bonding material of special fiber-opened glass cloth. Its dielectric constant is 3.2-3.3, which better enriches RO4835T and the existing RO4000 laminate material product series, with 3 mils, 4 Three thicknesses, ミル, そして 5 mils, are available. RO4450T prepreg material has very good dielectric constant tolerance control to provide consistent circuit performance; has a low z-axis thermal expansion coefficient to ensure the reliability of plated vias, and is compatible with standard epoxy/glass (FR-4 ) is compatible with the processing flow. For multi-layer designs that require multiple consecutive laminations, these materials are ideal as the fully cured RO4000 product can withstand multiple lamination cycles. Likewise, the RO4450T prepreg has a flame retardant rating of UL 94 V-0 and is compatible with lead-free processes. 2929 Bond Sheet is a non-reinforced thermoset resin-based film (1.5, 2, そして 3 mil thickness) bonding system for high-performance, high-reliability multilayer construction. The patented cross-linking resin system enables the film bonding system to be compatible with multiple lamination processes, while the controlled flow of glue can fill blind holes. Key Benefits Low dielectric constant (2.9) and tangent loss angle (.003) Ideal for multi-layer bonding Compatible with conventional processing methods Can be used with a variety of material types including PTFE Reliable multiple laminations.

2929 Prepreg is a thin, non-glass reinforced hydrocarbon bond sheet designed for high-performance, high-reliability multilayer construction. The product features a low dielectric constant (2.9) and low dielectric loss (<0.003) at microwave frequencies, making it ideal for making multi-layer boards with RT/duroidlSl6000, RO4000, and RO3000 series materials. This unique cross-linked resin system enables the thin adhesive sheet to be used in multiple continuous lamination processes. 同時に, its controllable fluidity has excellent blind hole filling ability, and the design requirements of blind grooves can be met by controlling the back-cut ratio.

ロジャース 2929 series PCB substrate parameters

The 2929 adhesive sheet can be laminated using conventional flatbed and vacuum chamber presses. It is currently available in thicknesses of 0.0015, 0.002, そして 0.003 インチ (0.038, 0.051, and 0.076mm) and can be added to the required thickness. This thin adhesive sheet without glass cloth reinforcement can be pre-pressed to the inner core board so that the core board and the adhesive layer can be grooved at the same time, and the carrier film can protect the adhesive sheet during machining and multi-layer boards. No contamination when boarding.

Label: ロジャース基板

モデル: 2929 BOND PLY 18X12 0020+-0002/DI, 2929 BOND PLY 18X24 0020+-0002/DI, 2929 BOND PLY 18X12 0015+-0001/DI, 2929

Category

Thin Hydrocarbon Bonding Sheet

Safety/Environmental Specifications

Lead-free

アプリケーション

Antenna Systems, Computing, IP Infrastructure, Test and Measurement

2929 prepreg is widely used in point-to-point microwave communications, automotive radar and sensors, base station antennas, パワーアンプ, phased array radars, radio frequency devices, patch antennas and power backplanes due to its excellent characteristics.

Advantages of 2929 Prepreg: Low dielectric constant and low dissipation factor, Ideal for multi-layer board bonding, Supports traditional processing methods, Compatible with different types of materials including PTFE materials, Reliable multiple consecutive laminations, Before slotting Can be pre-pressed to the inner core board, excellent blind hole filling ability, predictably control the thickness after pressing.

UGPCBのロゴ

UGPCBのロゴ