Rogers Cuclad シリーズには CuClad が含まれます 217, ククラッド 233, そしてCuClad 250 高周波PCB材料は、ガラス繊維/布で強化されたPTFE複合材料です。. 高周波用途のPCB基板およびレドームとして使用可能.

Rogers Cuclad Series High-Frequency PCB Substrate

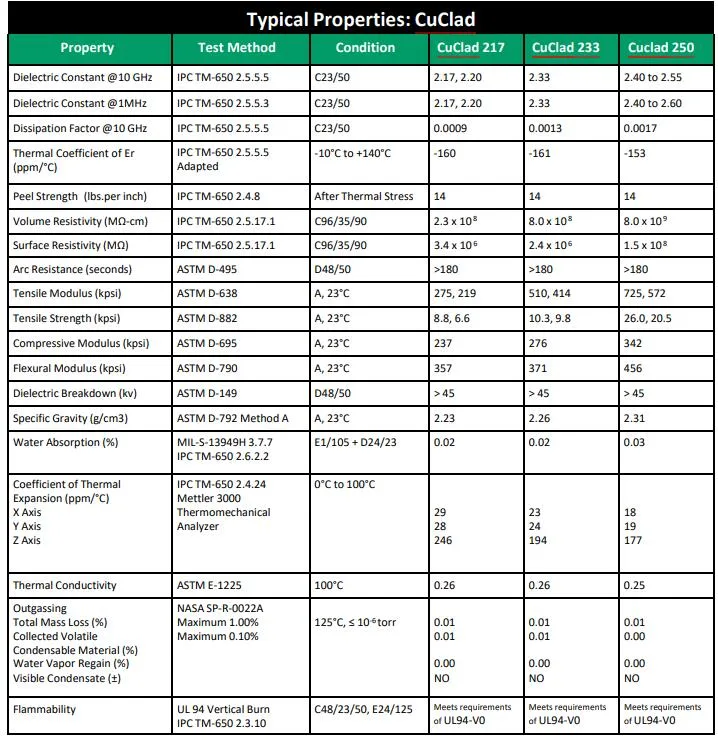

CuClad PCB material has low dielectric constant (DK), ranging from 2.17 に 2.60; Low dielectric loss, X-band loss angle tangent value between 0.0009 そして 0.0018, and low moisture absorption. The PCB material can be supplied in a maximum size of 36×48 インチ.

Advantages of CuClad PCB material

Stable dielectric constant with frequency

Suitable for broadband applications

Higher gain for amplifier and antenna design applications

Stable material characteristics can shorten the circuit development time

Adapt to larger PCB or radome requirements

ククラッド 217 PCB material

DK: 2.17 または 2.20

Use low glass fiber/PTFE ratio to achieve the lowest dielectric constant and loss factor among similar products

ククラッド 233 PCB material

DK:2.33

The medium glass fiber/PTFE ratio can balance reducing the dielectric coefficient with improving the loss factor without affecting the mechanical properties

ククラッド 250 PCB material

DK: 2.40 に 2.60

High glass fiber/PTFE ratio can provide mechanical properties close to traditional substrate

ククラッド 6250 adhesive film

DK:2.32

EAA thermoplastic copolymer adhesive film

ククラッド 6700 adhesive film

DK:2.35

CTFE thermoplastic copolymer adhesive film

Rogers Cuclad シリーズには CuClad が含まれます 217, ククラッド 233, そしてCuClad 250

High-frequency PCB substrate Rogers Cuclad series parameters.

ククラッド 217, ククラッド 233, そしてCuClad 250 PCB materials are woven glass/polytetrafluoroethylene composite materials used as important circuit board substrates. With the precise control of fiber glass/polytetrafluoroethylene film, the Cuclad Series can select a range of options, from the most negative double electric constant and loss tangent to the higher strengthened PCB material with better dimensional stability.

The woven glass fiber reinforced PTFE composites in the Cuclad Series products have greater dimensional stability than non-woven glass fiber reinforced PTFE composites with the same electrical constant. Through the consistency and control of PTFE coated glass fiber cloth, ロジャース – ARLON can provide more kinds of dielectric structures, and produce amino acid salts with better dielectric constant uniformity than similar non-woven glass fiber reinforced L amine acid salts. Selenium properties make Cucumber an attractive choice for filters, couplers and low noise amplifiers.

Cuclad PCB material and cross PCB material (the alternate layers of coated glass fiber layers face 90 to each other). This provides true electronic and mechanical isotropy in the xy plane, which is a feature of the Cuclad Series. No other woven or non-woven glass fiber reinforced PTFE PCB material makes this goal. Designers have found that this degree of anisotropy is crucial in some phased array antenna applications.

Cuclad 217 (ER=2.17, 2.20) uses a low glass fiber/polytetrafluoroethylene ratio to provide the Lo West di electrical constant and di spacing coefficient in the glass fiber reinforced polytetrafluoroethylene based PCB material.

These characteristics together provide faster signal propagation speed and higher signal-to-noise ratio.

Cuclad 233 (ER=2.33) uses medium glass fiber/PTFE ratio to balance low dielectric constant and improved dissipation coefficient without sacrificing mechanical properties.

Cuclad 250 (ER=2.40 – 2.60) adopts glass fiber/polytetrafluoroethylene which is higher than glass fiber/polytetrafluoroethylene, and its mechanical properties are equivalent to those of traditional sublayer. In all rectifier circuits, better dimensional stability and lower thermal expansion rate are other important advantages. The electrical performance of CuClad 250GT and CuClad 250GXA was tested at 1MHz and 10GHz respectively.

For key performance applications, “LX” test level can be specified for Cuclad Series products; This means that each piece of paper will be tested separately and a test report will be issued with the order.

Brand

ロジャース

モデル

ククラッド 217、ククラッド、ククラッド 233、ククラッド 250、CuClad Series

PCB category

Microwave circuit board, PTFE/glass fiber braided PCB material microwave printed circuit board substrate

Application of Cuclad Series PCB materials (ククラッド 217, ククラッド 233, ククラッド 250)

Locomotive, 鉄道輸送, electric power, renewable energy, body and chassis, lighting, equipment and inverter power supply, national defense industrial equipment, on-board, on-board communication, on-board entertainment, Internet of Vehicles, industrial automation, industrial servo, indoor lighting, smart home, industrial equipment control, mobile phone related, electric vehicle power system, 通信機器, Internet of Things, storage, security system, military electronics (レーダー, electronic countermeasure, electronic countermeasure), Microwave components (LNA, filter, カプラー, 等),

UGPCBのロゴ

UGPCBのロゴ