Rogers PCB RT/duroid 6035HTC Material

High-Frequency Circuit Materials for Powerful Applications

Rogers PCB RT/duroid 6035HTC high frequency circuit materials are ceramic filled PTFE composites designed for use in high power RF and microwave applications. This material is an exceptional choice for demanding high power scenarios, offering superior thermal conductivity and excellent long-term thermal stability with copper foil (ED and reverse treat).

Superior Thermal Conductivity

The RT/duroid 6035HTC laminates boast a thermal conductivity nearly 2.4 times higher than that of standard RT/duroid 6000 products. This significant improvement enhances the material’s ability to dissipate heat effectively, making it ideal for high power applications. さらに, ロジャース’ advanced filler system ensures excellent drill-ability, reducing drilling costs compared to standard high thermally conductive laminates that utilize alumina fillers.

主な特長

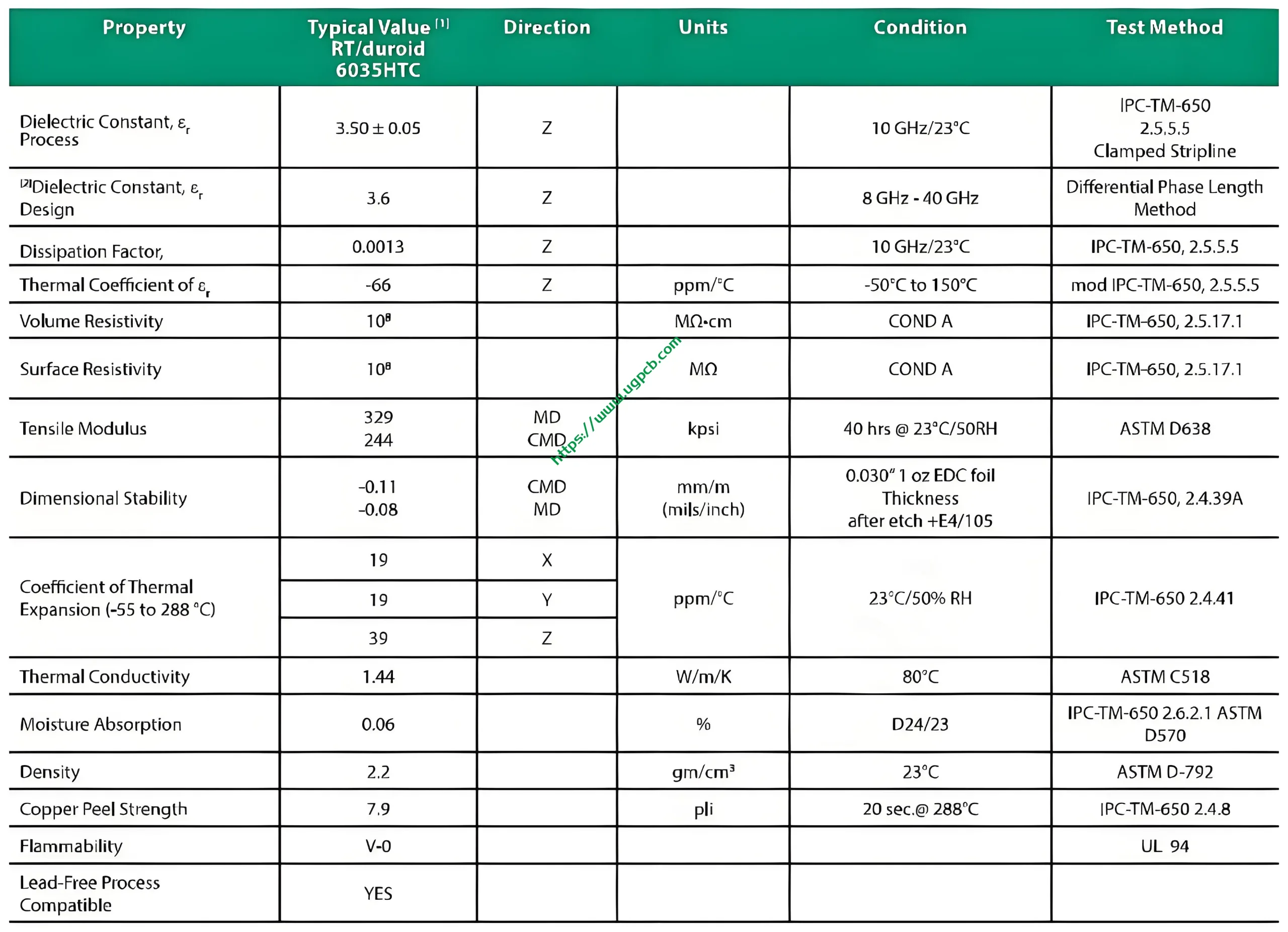

- 誘電率: 3.50 +/- .05

- 損失係数: .0013 at 10GHz

- 熱伝導率: 1.44 W/m/K at 80°C

- 銅箔: Thermally stable low profile and reverse treat

Benefits of RT/duroid 6035HTC

Enhanced Performance

- High Thermal Conductivity: Ensures efficient heat dissipation.

- Improved Dielectric Heat Dissipation: Enables lower operating temperatures for high power applications.

- Excellent High Frequency Performance: Maintains signal integrity at high frequencies.

- Lower Insertion Loss: Reduces signal loss, enhancing overall efficiency.

- Thermal Stability of Traces: Ensures long-lasting performance and reliability.

By choosing Rogers PCB RT/duroid 6035HTC material, you benefit from a combination of high thermal conductivity, excellent drill-ability, and superior electrical performance, making it the optimal choice for high power RF and microwave applications.

UGPCBのロゴ

UGPCBのロゴ