PCB: 현대 전자 장치의 심장 박동

PCB, 인쇄 회로 기판의 약자, 현대 전자 장치의 중추 역할을 합니다.. 기본 기판으로 구성됨, 단열재, 그리고 동박, PCB는 인쇄 및 에칭 공정을 활용하여 회로를 만듭니다.. 대안으로 PWB로 알려져 있습니다 (인쇄 된 와이어 보드) 미국과 영국에서, 이 보드는 다양한 전자 구성 요소를 지원하고 연결하는 데 중요합니다..

PCB의 역할

PCB는 PCBA 보드 내의 전자 어셈블리를 지원할뿐만 아니라 다양한 전자 부품에 대한 회로 연결을 제공하는 중요한 전자 구성 요소입니다.. 커패시터를 연결하여, 저항기, 인덕터, IC 칩, 그리고 다른 필요한 구성 요소, PCBS는 전자 장치의 마더 보드 또는 메인 보드 역할을합니다..

거의 모든 전자 가제트, 헤드폰 및 배터리에서 컴퓨터까지, 통신 장비, 비행기, 위성, 자동차, 선박, 의료기기, PCB에 의존합니다. PCB, 인쇄 회로 보드 어셈블리를 나타냅니다, 다양한 전자 부품으로 채워진 PCB를 나타냅니다.

PCB의 기원

PCB의 역사는 다시 시작됩니다 1925 Charles Ducas, 부가 과정의 선구자, 절연 기판에서 회로 패턴을 인쇄하고 전기 도금을 사용하여 배선을위한 도체가 성공적으로 생성되었습니다.. ~ 안에 1936, Paul Eisler, 빼기 과정의 선구자, 처음으로 라디오에서 PCB를 사용했습니다.

군용 라디오에서 PCB 기술의 적용이 시작되었습니다. 1943, 그리고 by 1948, 미국은 공식적으로 상업용 PCB를 승인했습니다. 1950 년대, CCL 및 라미네이트 보드의 결합 강도 및 용해성 문제 해결으로, 구리 에칭 방법은 주류가되었습니다, 그리고 PCB는 널리 사용되기 시작했습니다. 그 이후로, PCB는 전자 산업을 지배했습니다.

PCB 기술의 진화

1950 년대 단일 PCB에서 다음 수십 년 동안 양면 PCB, 그리고 다층 PCB, 업계는 상당한 발전을 목격했습니다. 1970 년대에는 다층 PCB에서 급속한 발전이있었습니다, 높은 정밀도로 이동합니다, 고밀도, 미세한 선, 작은 구멍, 높은 신뢰성, 저렴한 비용, 자동화 된 연속 생산.

1980 년대, 표면 실장 기술 (SMT) 구멍 장착을 점차적으로 교체했습니다, 초고 다층 PCB 및 고밀도 상호 연결 (HDI) 보드가 번성했습니다. 1990 년대까지, 포장 기술은 쿼드 플랫 패키지에서 발전했습니다 (MFF) 볼 그리드 어레이 (BGA), PCB가 더 작은 회로를 개발하도록 촉구합니다.

21 세기로, 고밀도 BGA, 칩 스케일 포장, IC 포장 기판을위한 유기 라미네이트 재료는 PCB 기술의 급속한 성장을 보였습니다.. PCB는 단일 계층에서 더블 레이어로 진화했습니다, 다층, 유연한, 단단한 융통성 조합, 금속 기반, 세라믹, 그리고 더, 각각 고유 한 개발 추세를 유지합니다.

PCB의 기능

PCB 앞에, 전자 구성 요소는 와이어를 통해 상호 연결되었습니다. PCB는 통합 회로 및 기타 전자 부품을 고정 및 조립하는 데 기계적 지원을 제공합니다., 배선 및 전원 연결 활성화 (신호 전송) 또는 그들 사이의 전기 절연. 또한 특징적인 임피던스와 같은 필요한 전기 특성을 제공합니다..

전자 장치에서 PCB를 채택하면 수동 배선과 관련된 오류가 피할 수 있습니다., 자동 구성 요소 삽입 또는 장착을 용이하게합니다, 납땜, 그리고 테스트, 제품 품질 보장, 생산성 향상, 비용 절감, 유지 보수를 단순화합니다. PCB는 어셈블리 및 납땜을 단순화합니다, 기존 배선 워크로드를 줄입니다, 노동 강도를 밝게한다.

PCB의 분류

응용 프로그램에 의해

- 소비자 PCB: 장난감에 사용됩니다, 카메라, 텔레비전, 오디오 장비, 휴대폰, 허파, 가정 기기, 등.

- 산업용 PCB: 보안에 사용됩니다, 자동차, 컴퓨터, 통신 장치, 악기, 산업 컨트롤러, 등.

- 군용 PCB: 항공 우주에서 사용됩니다, 레이더, 군용 선박, 및 군사 통신 장비.

기본 재료에 의해

- 종이 기반 PCB: 페놀 종이 기반 및 에폭시 종이 기반.

- 유리 천 기반 PCB: 에폭시 유리 천 기반 및 테플론 유리 천 기반.

- 합성 섬유 PCB: 에폭시 합성 섬유 기반.

- 유기 영화 기반 PCB: 나일론 필름 기반.

- 세라믹 기판 PCB.

- 금속 코어 기반 PCB: 철, 알류미늄, 구리.

- 탄화수소 화합물 PCB.

- 세라믹 파우더 PCB.

- PTFE, 테플론 PCB.

구조 별

- 견고한 PCB

- 유연한 PCB

- 강성 융통성 조합 PCB

레이어 수에 의해

- 단면 PCB: 한쪽에 구성 요소와 표시가있는 1 층 보드와 다른쪽에 회로 회로.

- 양면 PCB: 양쪽의 회로는 VIA를 통해 연결됩니다.

- 다층 PCB: 내부 회로 레이어를 포함합니다, 일반적으로 4 에게 20 레이어.

- HDI PCB: 마이크로 vias 및 묻힌 VIA와 고밀도 상호 연결 보드, 일반적으로 휴대폰 마더 보드에서 사용됩니다.

PCB의 구조

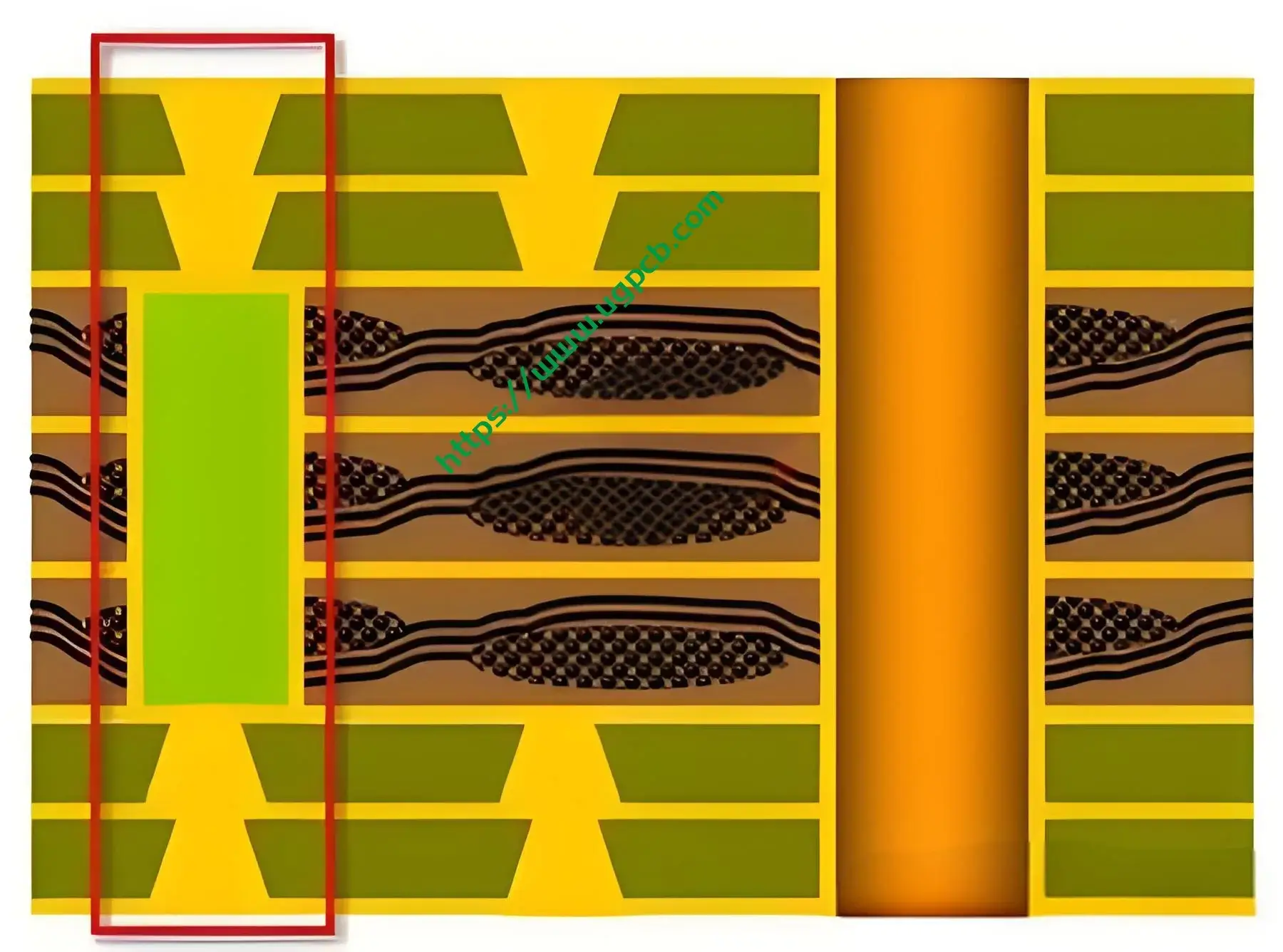

PCB는 구리 클래드 라미네이트로 구성됩니다 (CCL), 프리프레그 (PP 시트), 구리박, 솔더 마스크 (솔더 저항이라고도합니다), 및 실크 스크린 레이어. 표면 처리는 노출 된 구리 호일을 산화로부터 보호하고 효과적인 납땜을 보장합니다..

CCL (구리 클래드 라미네이트)

CCL, 또는 구리로 입은 라미네이트, 유리 섬유 천을 결합하여 만든 복합 재료입니다.. CCL은 PCB를 제조하는 기본 재료입니다, 전도도 제공, 격리, 지원. 성능, 품질, PCB의 제조 비용은 크게 CCL에 따라 다릅니다.

프리프레그 (PP 시트)

프리프레그, PP 시트라고도합니다, 다층 PCB 생산에 사용되는 주요 재료 중 하나입니다.. 유리 섬유 천과 같은 수지 및 보강재로 구성됩니다.. 열과 압력 하에서 부드럽고 냉각시 굳어집니다..

구리 포일 – 회로 레이어

구리 호일, 얇은, PCB 기판에 증착 된 연속 금속 포일, 지휘자 역할을합니다. 그것은 절연 층을 준수하고 에칭되어 회로 패턴을 형성합니다.. 일반적인 구리 포일 유형에는 롤 구리 호일이 포함됩니다 (라) 및 전해 구리 포일 (에드).

솔더 마스크

솔더 마스크, 일반적으로 녹색이지만 빨간색으로도 제공됩니다, 검은색, 그리고 파란색, PCB의 영구 보호 계층입니다, 수분 방지, 부식, 곰팡이, 그리고 기계적 손상. 또한 구성 요소가 잘못 납땜되는 것을 방지합니다.

실크 스크린 레이어

실크 스크린 레이어, 일반적으로 솔더 마스크 위에 위치합니다, 구성 요소 값과 같은 주석 및 레이블을 제공합니다, 요점, 제조업체 로고, 생산 날짜, PCBA 설치 및 유지 보수 지원.

PCB 표면 처리

표면 처리는 PCB의 연결 지점을 코팅하는 것을 말합니다., 패드 또는 접점과 같은, 보호 층으로. 일반적인 표면 처리에는 납 주석 도금이 포함됩니다, 무연 주석 도금, 유기 납땜성 방부제 (OSP), 전기 니켈/침지 금 (동의하다), 침수은, 침지 주석, 그리고 금 손가락 도금. 환경 규제가 강화됩니다, 납 주석 도금이 단계적으로 폐지되었습니다, 그리고 대부분의 PCB는 이제 ROH 및 할로겐이없는 제조 공정을 준수합니다..

결론

PCB는 현대 전자 제품에서 필수 불가결 구성 요소입니다, 오류가없는 배선을 용이하게합니다, 자동 조립품, 비용 효율적인 생산. 기술이 발전함에 따라, PCB는 계속 적응합니다, 그들이 전자 혁신의 초석으로 남아 있는지 확인합니다.

UGPCB 로고

UGPCB 로고

매우 멋지다, 나는 즉시 사용했다.