Aito M9 테일 라이트 소개

Aito M9 테일 라이트 소개

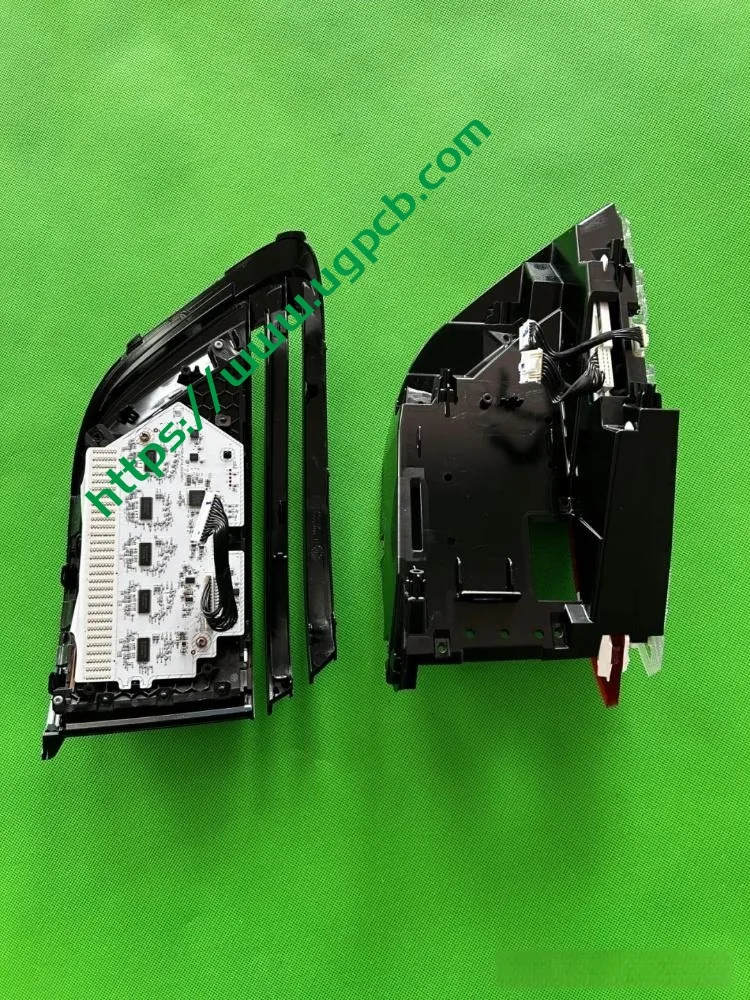

최근에, AITO M9용 고구성 헤드라이트와 테일라이트 세트를 획득했습니다. DLP 헤드라이트는 광범위한 분해가 필요하기 때문에, 우리는 후미등 분해를 먼저 보여주기로 결정했습니다. 문제의 꼬리 빛은 측면 꼬리 빛입니다. (램프), 포지셔닝과 같은 기능을 제공합니다, 제동, 선회, 그리고 ISD 상호 작용.

꼬리 빛의 분해

주택 분리부터 시작합니다, 우리는 건조제가 거의 자동차 조명의 표준 기능이된다는 것을 알았습니다., 중국 소비자의 까다로운 특성을 반영합니다. 제조업체는 소비자 불만을 줄인 건조제를 통합하는 데 드는 비용을 무게로.

테일 라이트의 구성 요소

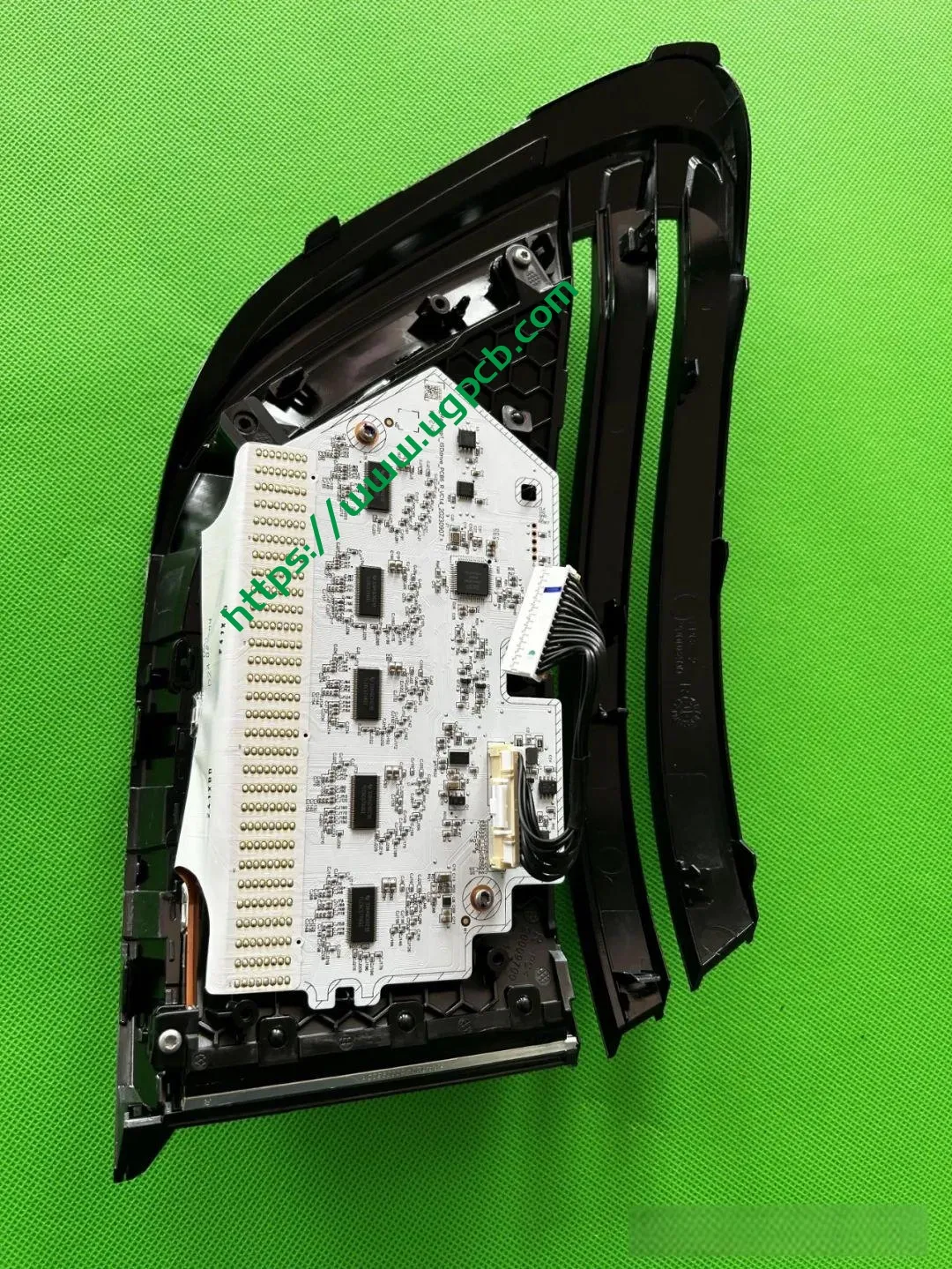

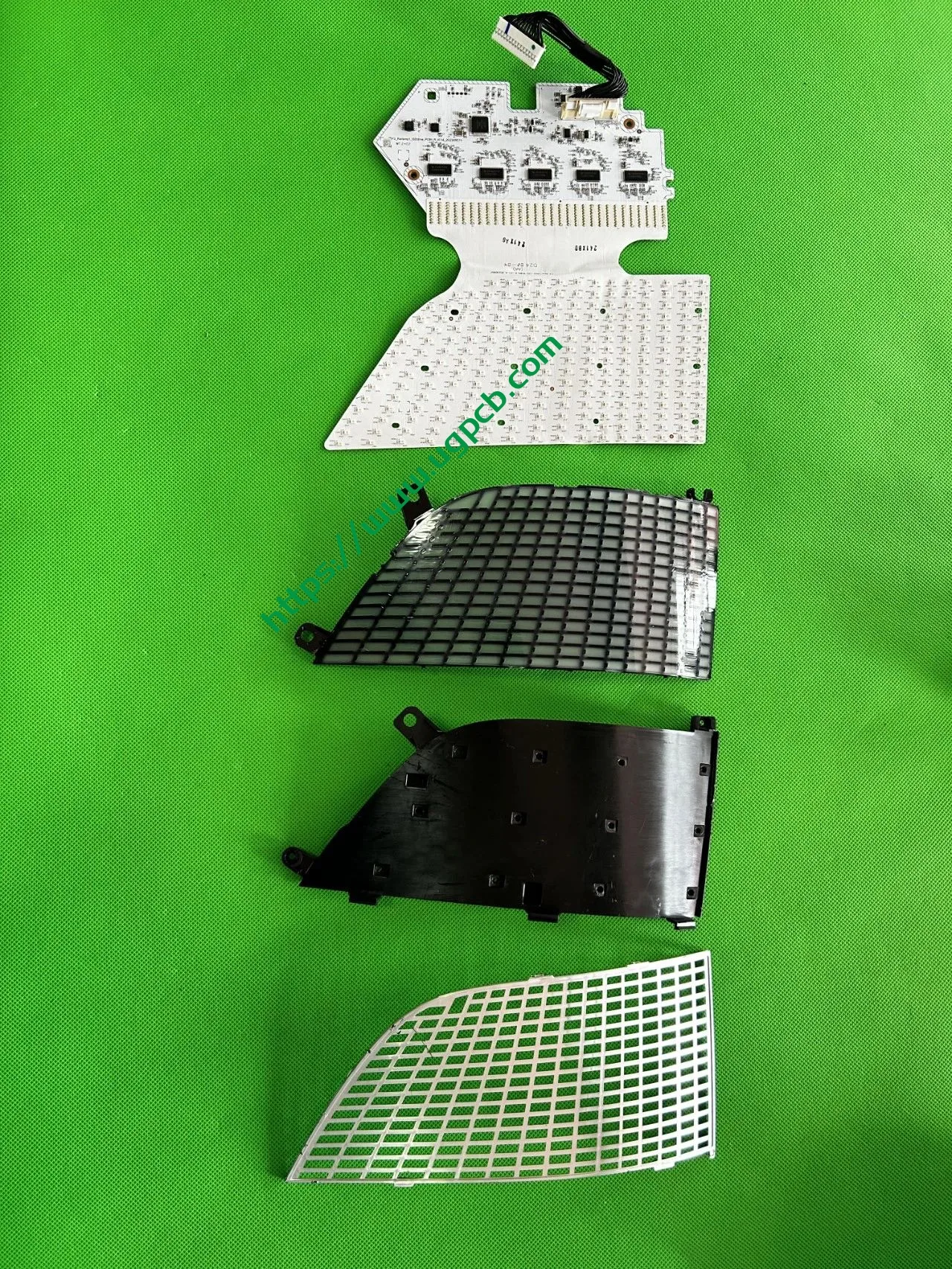

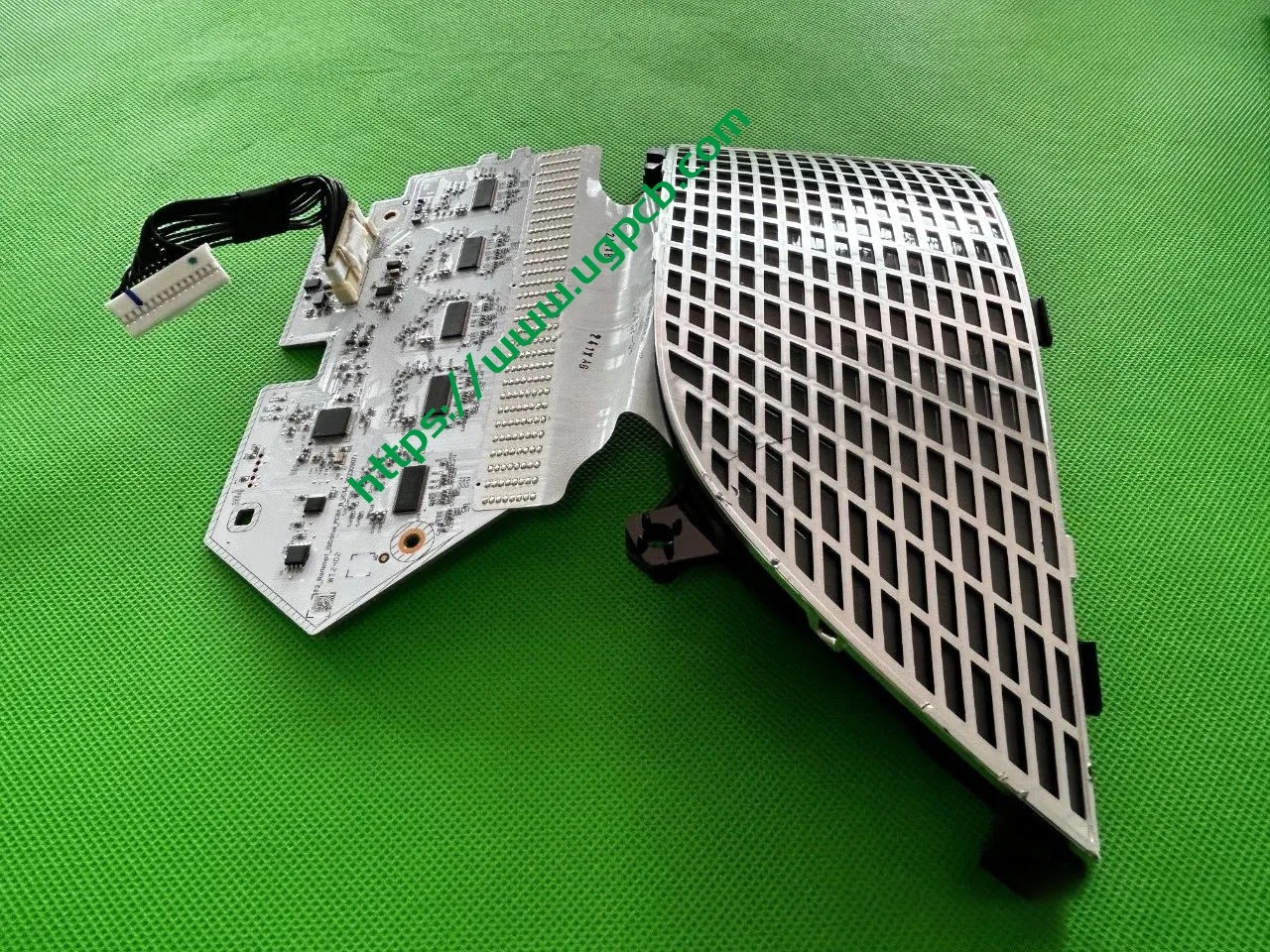

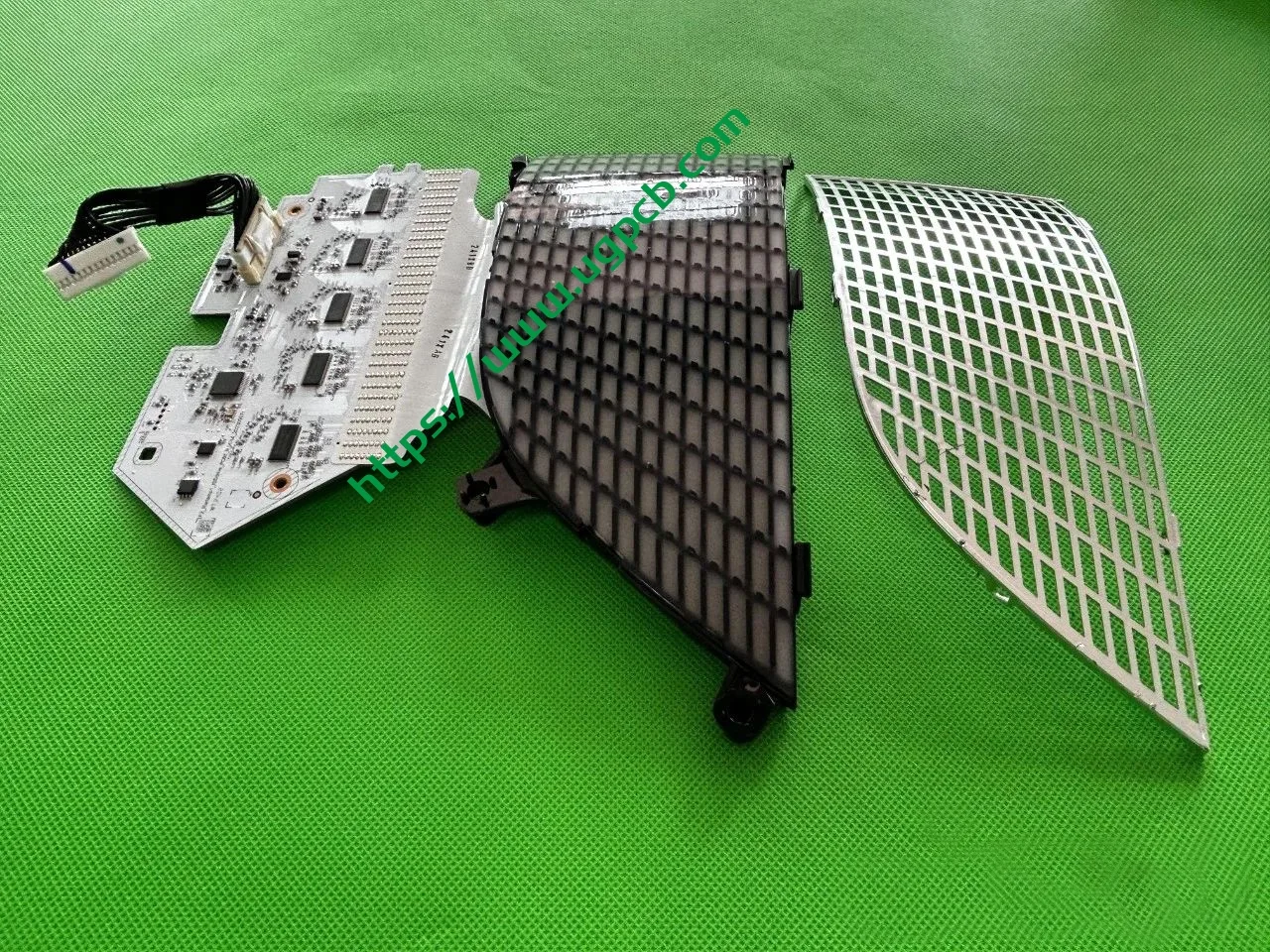

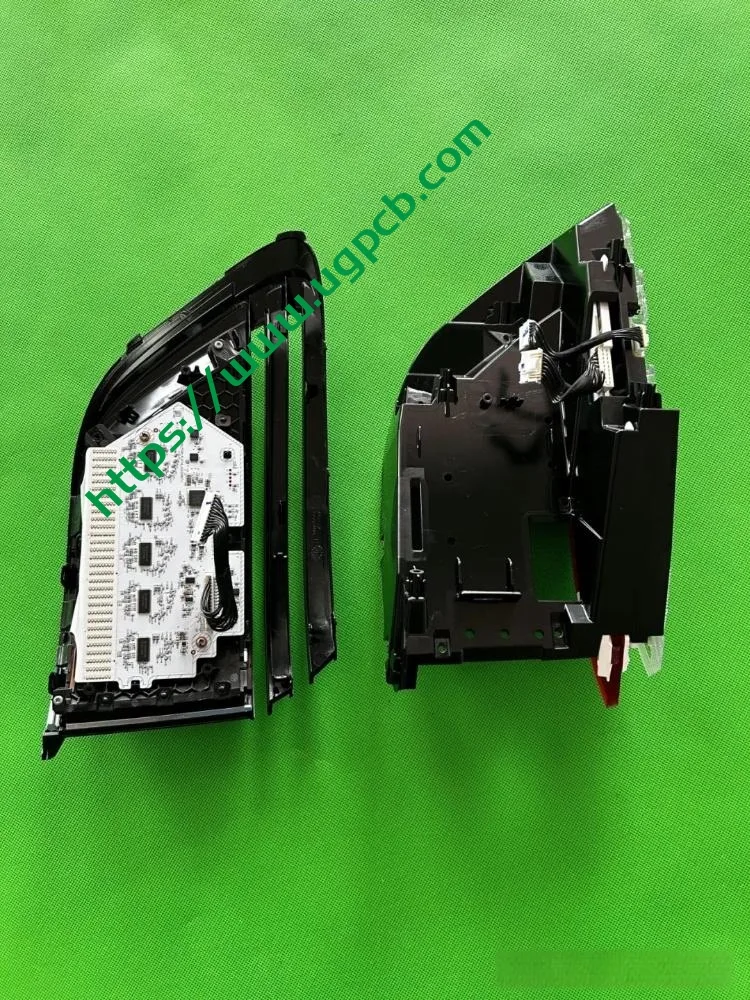

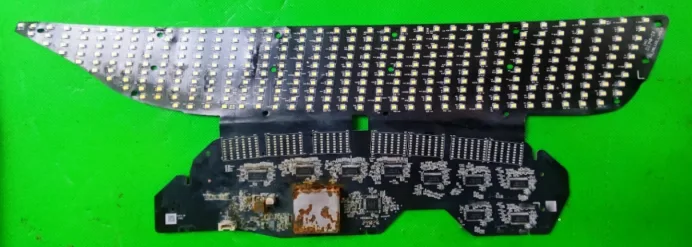

테일 라이트의 중간 부분은 주로 두 부분으로 구성됩니다.: 신호 표시등 섹션 및 ISD 대화식 디스플레이 섹션. 신호광 섹션은 두 개의 두꺼운 벽 렌즈를 사용합니다, 그중 하나는 빨간색입니다, 상대적으로 드문 일입니다. ISD 섹션은 드라이브 제어 보드와 LED 보드를 사용합니다., 유연한 보드로 연결되었습니다, 비교적 비싼 솔루션을 나타냅니다.

ISD 화면의 명확성

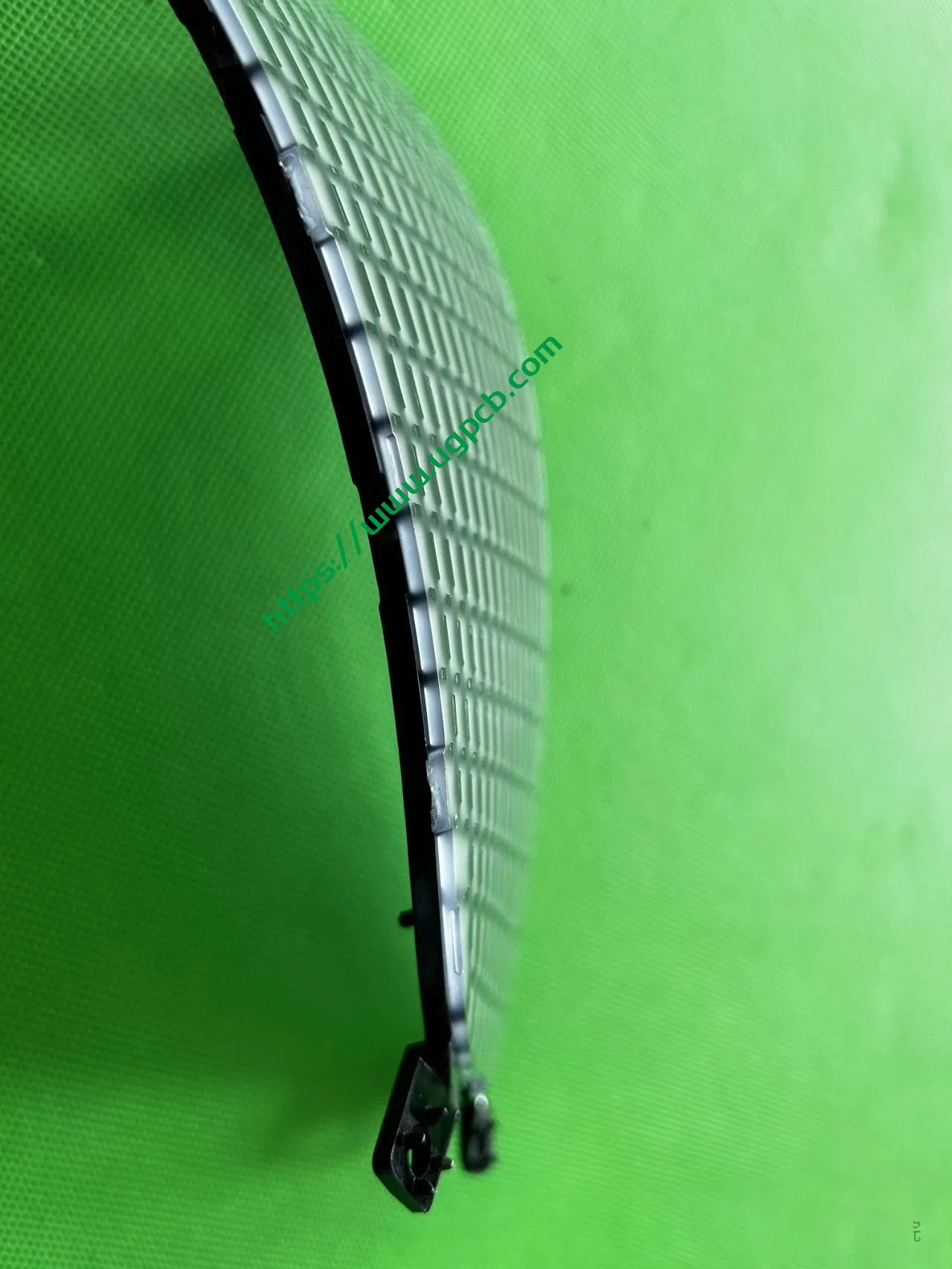

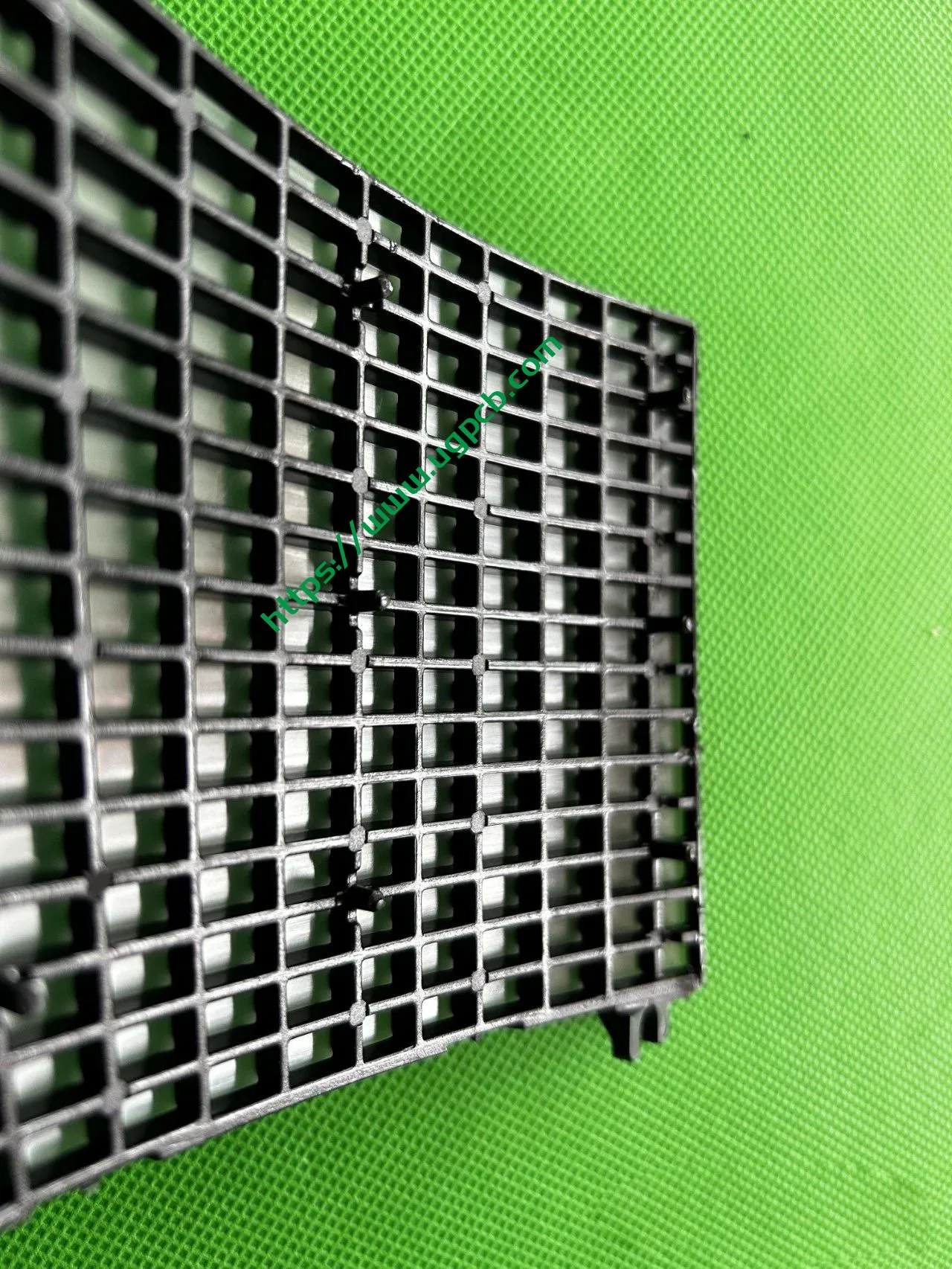

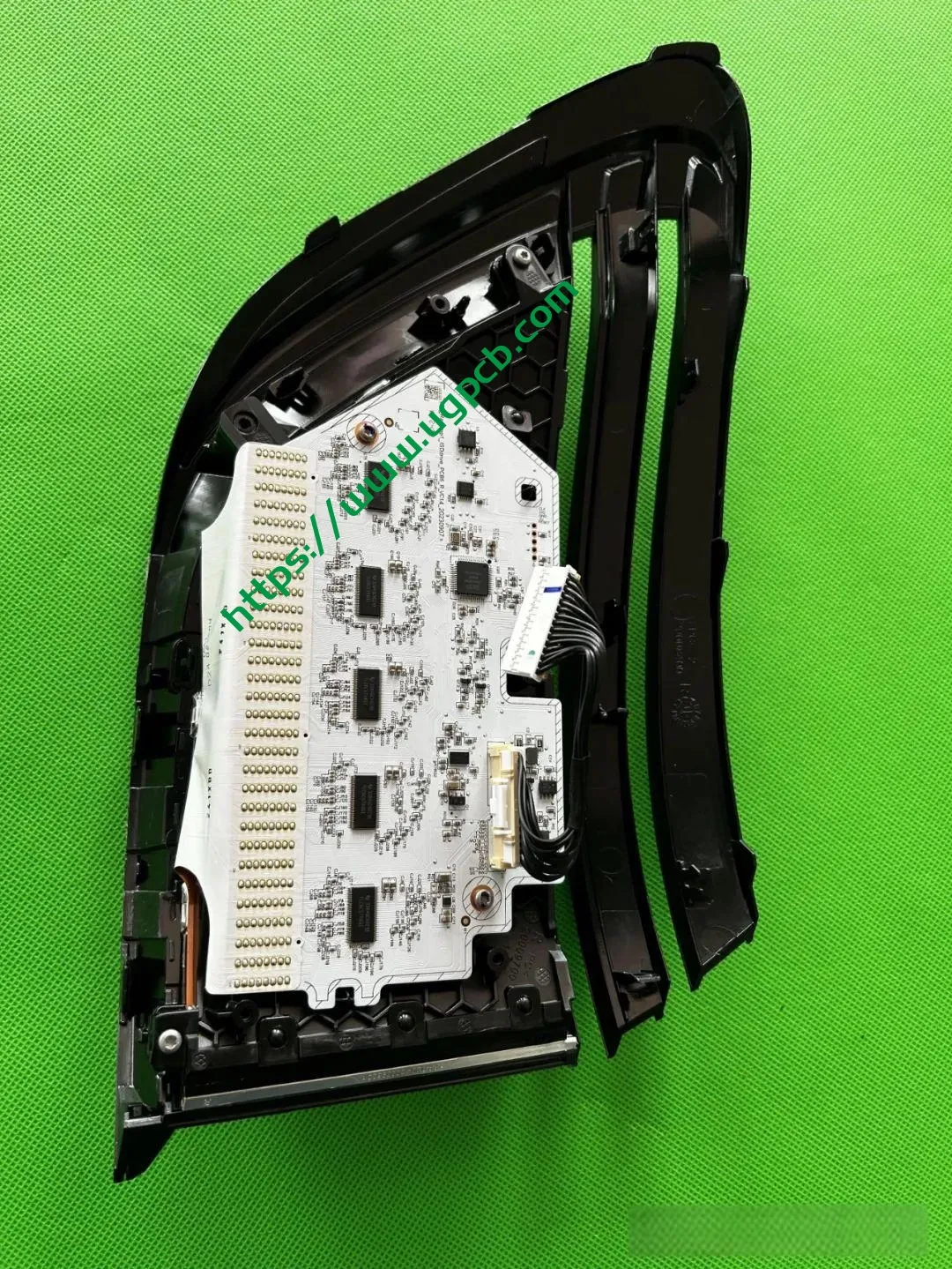

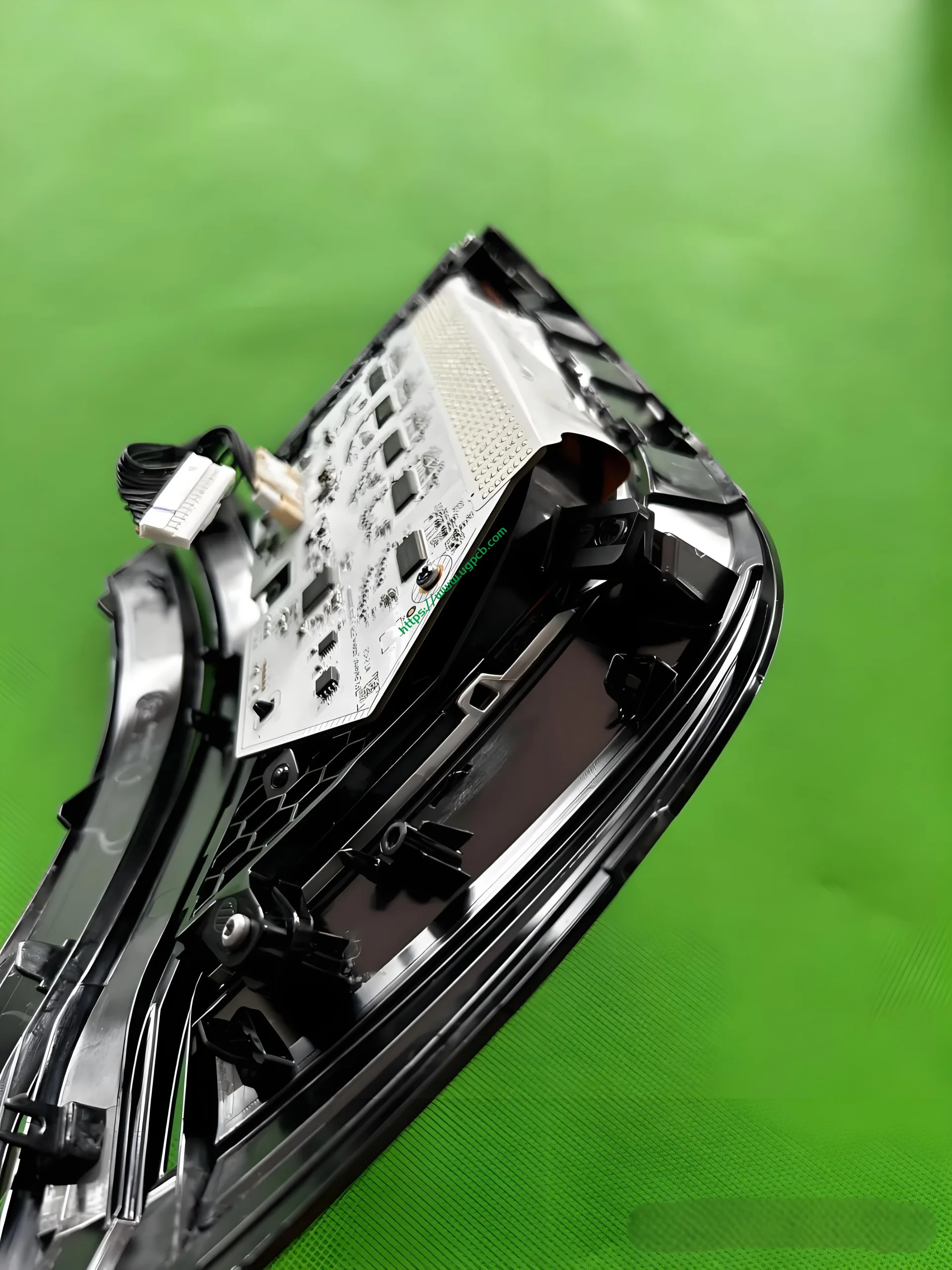

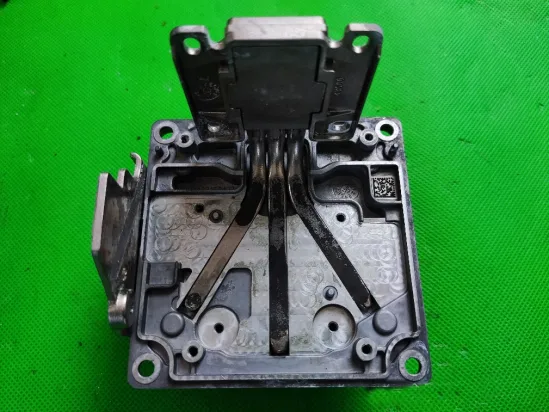

제한된 수의 픽셀에도 불구하고, 이 테일 라이트의 ISD 화면은 빛의 누출없이 높은 선명도를 제공합니다.. 구조적으로, 바닥에는베이스 플레이트가 있습니다, 위의 LED 보드입니다. LED 보드는 바이컬러 내부 덮개로 덮여 있습니다. (검은색 + 디퓨저 재료), 가벼운 누출을 방지하기 위해 알루미늄 코팅 브래킷이 이어집니다. 외부에는 또 다른 바이 컬러 내부 덮개가 있습니다 (검은색 + 투명한). 총, 세 가지 방지 구조 구성 요소가 있습니다, 가벼운 누출을 크게 만듭니다.

제조업체 정보

이 테일 라이트는 Xingyu에 의해 제조됩니다.

Aito M9 DLP 헤드 라이트 소개

DLP 프로젝션 헤드 라이트는 새로운 것이 아닙니다, 메르세데스-벤츠와 같은 럭셔리 브랜드에서 사용했습니다, 아우디, 그리고 랜드 로버, Hiphi 및 IM Motors와 같은 국내 자동차 제조업체뿐만 아니라. 하지만, 화웨이의 참여와 함께, 이 기술은 상당한 관심을 끌었습니다, 국내 자동차 제조업체가 HD에서 DLP 솔루션으로 전환하도록 프롬프트. 오늘, 이전에 HIPHI X의 프로젝션 헤드 라이트를 해부 한 후 Huawei의 DLP 프로젝션 헤드 라이트를 해체 할 것입니다..

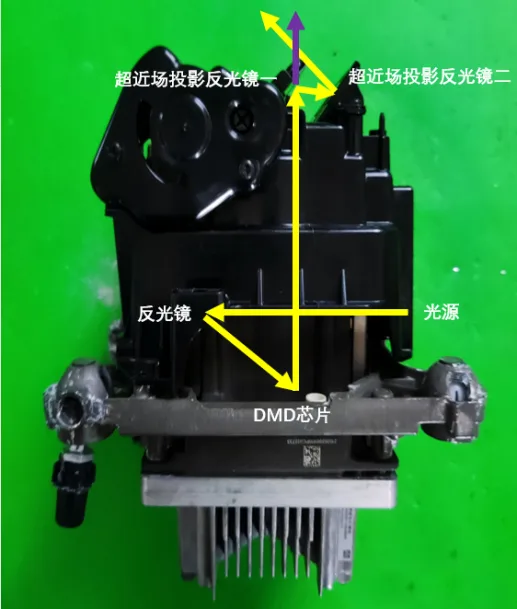

DLP 헤드 라이트의 구성 요소

다음은 헤드 라이트의 기능 다이어그램입니다, 고급스러운 구성을 전시합니다. 펜더에서 그릴까지, 낮은 빔 렌즈가 있습니다, 84-픽셀 ADB 렌즈, 및 DLP 투영 렌즈, 두꺼운 벽으로 된 가이드로 분리됩니다. 아래는 ISD 대화식 조명입니다. 이 기사에서, 우리는 ISD 대화 형 라이트 및 신호 라이트 섹션에 중점을 둘 것입니다..

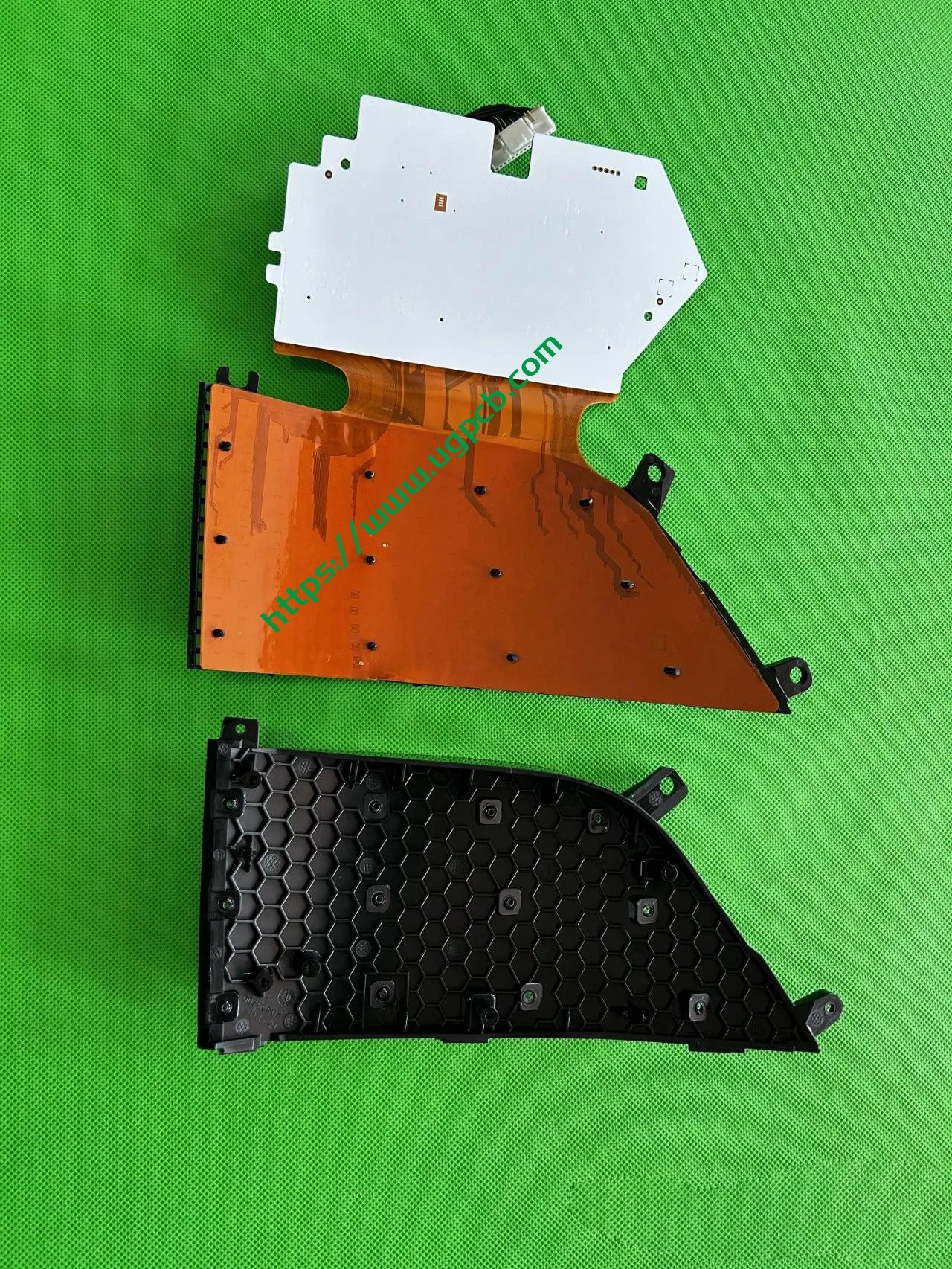

ISD 체계의 설계

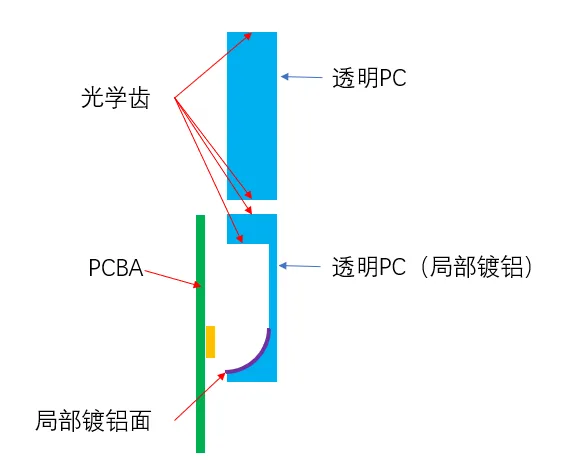

이 조명이 ISD 개념을 사용하는 첫 번째 조명은 아니지만, 자세한 디자인에서 독특한 장점이 있습니다. 폭발 된 전망을 살펴 보겠습니다: 까치발 + FPC + 내부 렌즈 (바이 컬러 – 검은색 + 디퓨저) + 알루미늄 코팅 된 라이트 블로킹 브래킷 + 두 번째 내부 렌즈 (바이 컬러 – 검은색 + 투명한) + 메인 프레임.

제조 공정에는 두 개의 하위 어셈블리가 포함됩니다: 첫 번째는 브래킷으로 구성됩니다, FPC, 그리고 내부 렌즈 (열 리벳 팅 사용), 그리고 두 번째는 알루미늄 코팅 된 광 블록 브래킷으로 구성됩니다, 두 번째 내부 렌즈, 그리고 메인 프레임 (열 리벳과 레이저 용접 사용).

ISD 체계의 디자인 세부 사항

이 ISD 솔루션은 3 개의 쌓인 구성 요소에서 픽셀 누출을 고려합니다.. 주목할만한 세부 사항을 살펴 보겠습니다. 첫 번째와 두 번째 내부 렌즈 사이의 알루미늄 코팅 된 광개 차단 브래킷은 알루미늄으로 코팅 된 PP-TD20 재료를 사용합니다., 부드럽고 얇은 벽입니다, 내부 렌즈와 외부 렌즈 사이의 간격을 효과적으로 연결하고 정적 조건에서 밝기 향상.

정적 효과 비교

다음은 알루미늄 코팅 된 광개 차단 브래킷이 있거나없는 정적 효과의 비교입니다. (물리적 차이는 중요합니다).

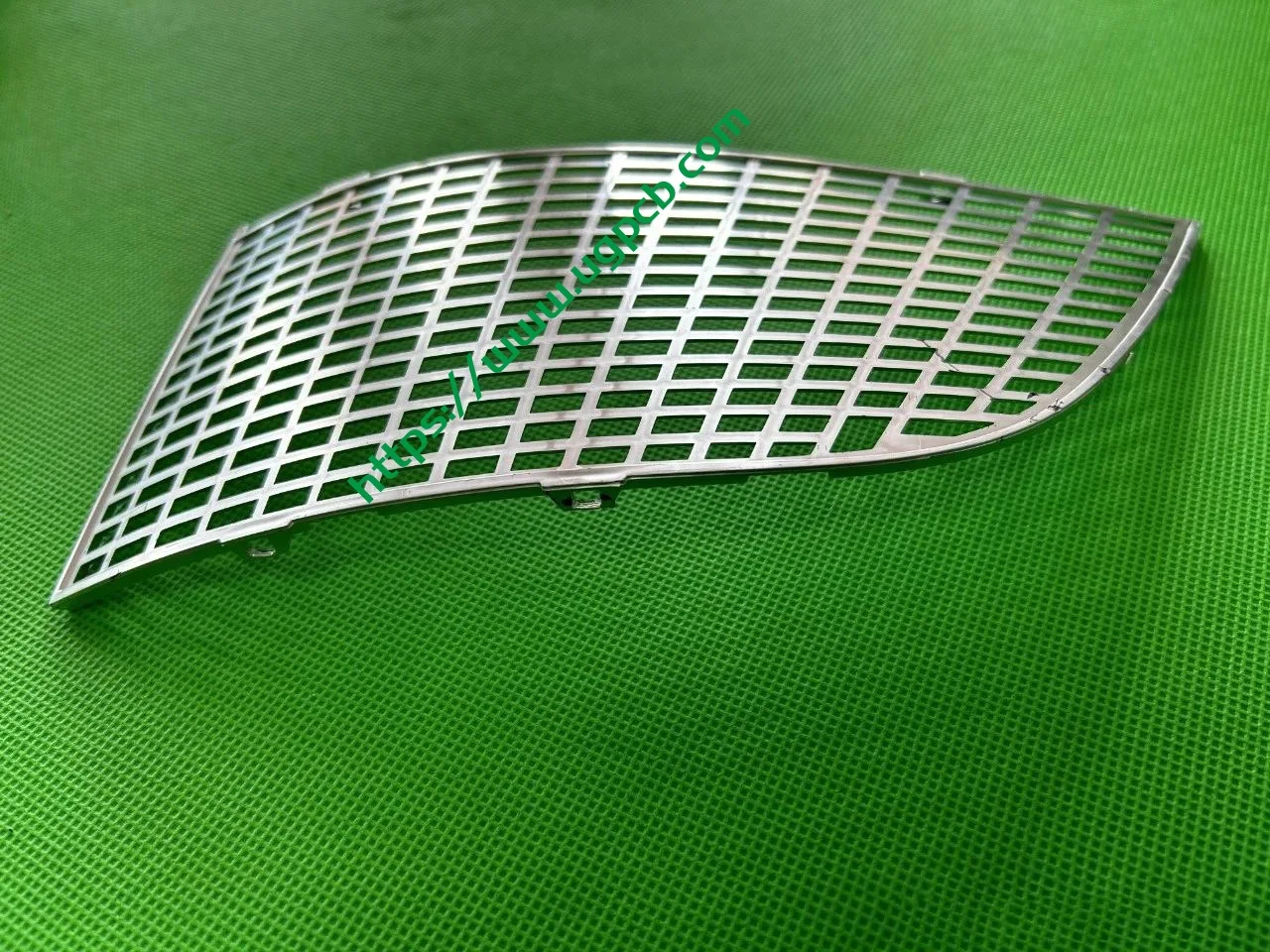

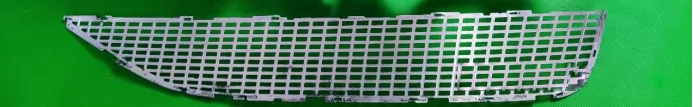

신호등 섹션

주간 달리기 조명, 신호를 돌리십시오, 그리고 위치 표시등 Bicolor LED를 사용하여 일반적인 광 방출 영역을 공유합니다.. 광학 성분은 클립으로 연결된 어셈블리입니다, 그리고 명확성을 위해, 우리는 손으로 그린 단면을 제공했습니다.

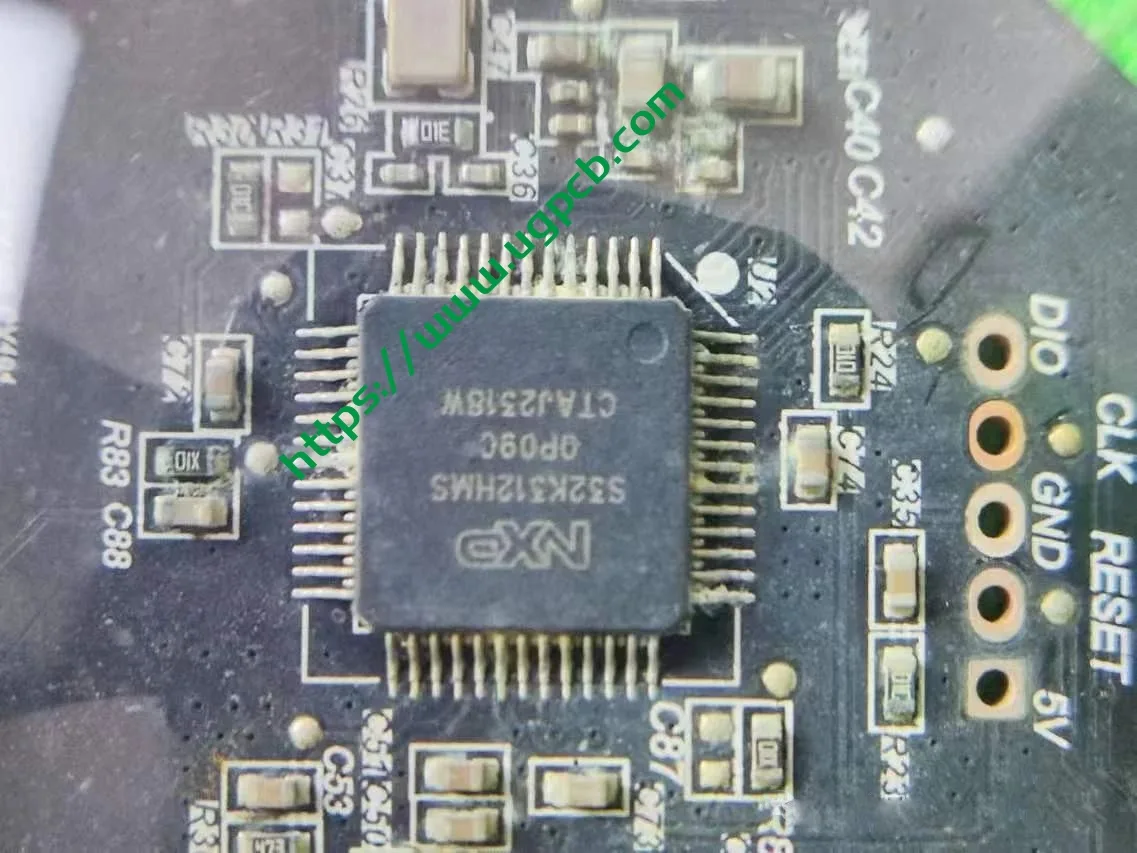

PCBA 및 장착

PCBA 및 검은 색 브래킷은 나사로 광학 구성 요소에 고정되어 있습니다.. 흥미로운 디자인 선택은 PCBA 용 설치 나사 및 포지셔닝 핀이 LED의 양쪽에 배포된다는 것입니다.. 우리는이 디자인에 대한 당신의 생각을 주석에서 환영합니다.

신호 전등 보드의 구성 요소

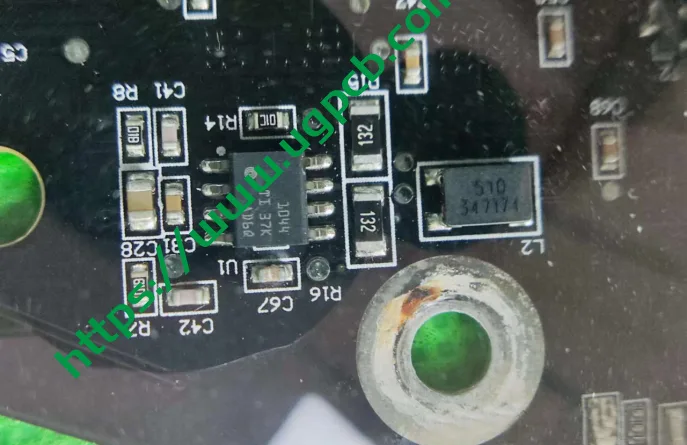

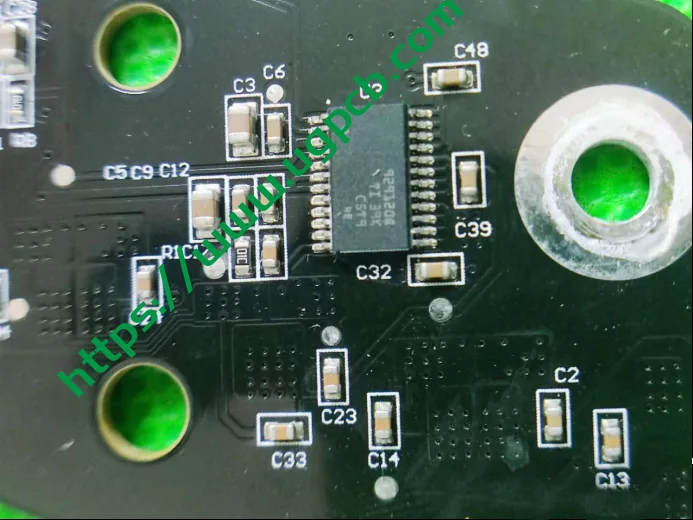

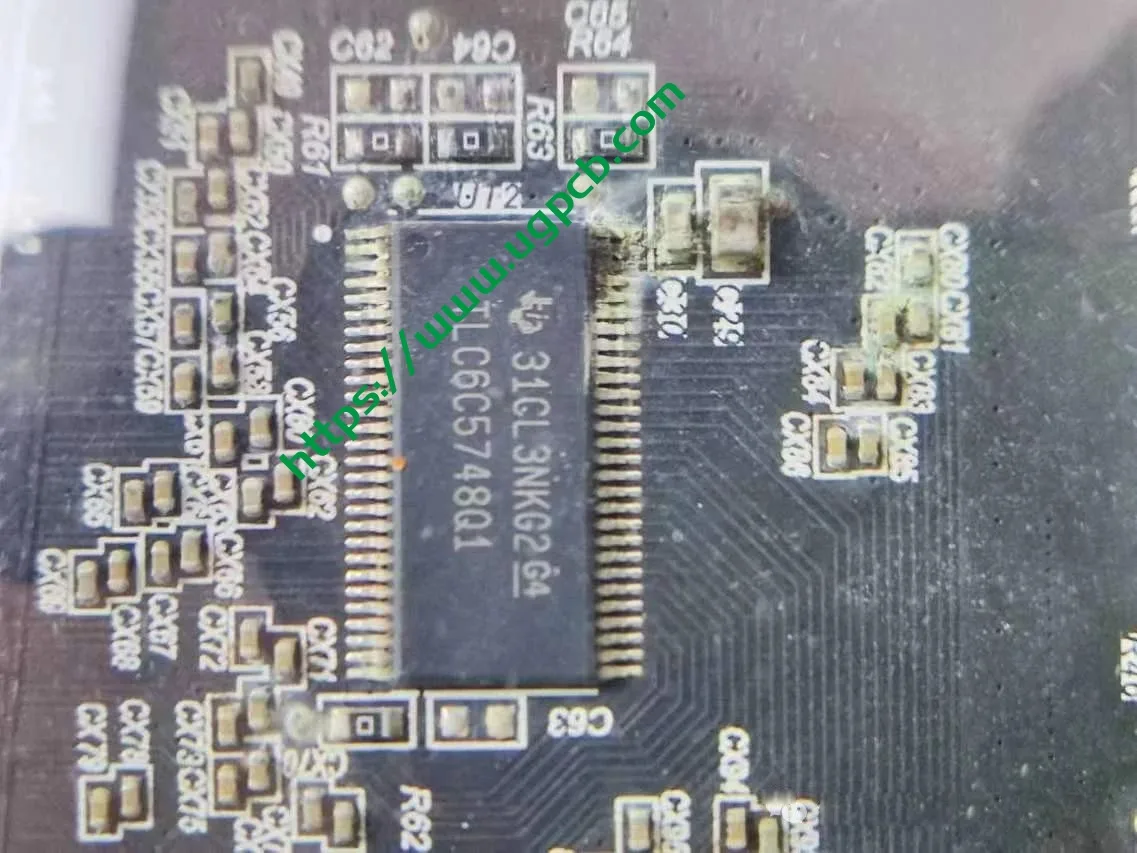

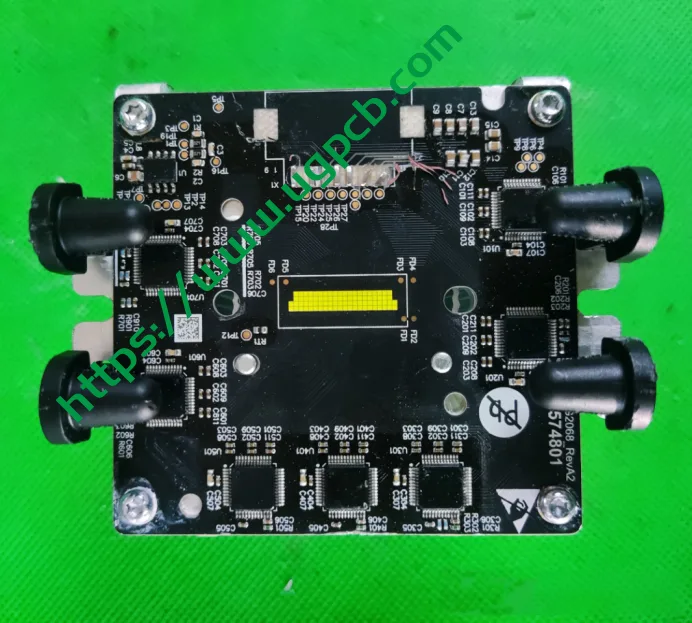

신호 라이트 보드는 TI를 사용합니다 1044 트랜시버 칩이 가능합니다, 7 개의 12 채널 TPS929120Q LED 직접 드라이브 칩 LED, 그리고 40 Bicolor LED.

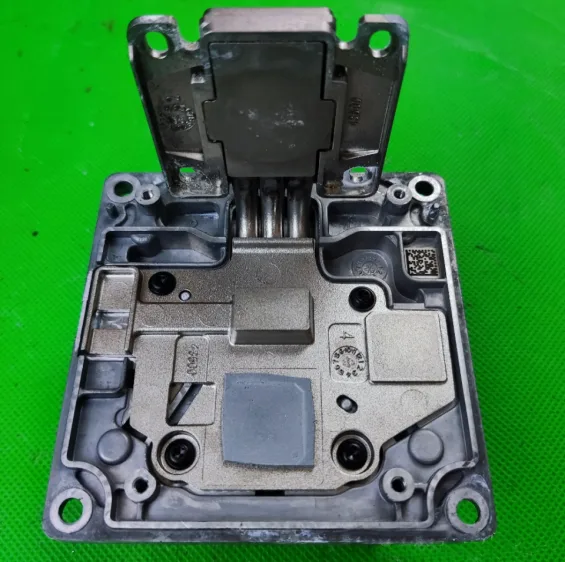

기본 광원 및 DLP 모듈의 분해

지금, 메인 광원과 화웨이의 DLP 모듈로 이동합시다. 1.3 메가 픽셀 모듈에 대한 세부 정보를 제공 할 것입니다. 첫 번째, 이전 청중의 질문에 대답합니다, ISD LED는 특정 칩에 의해 구동됩니다, 아래 다이어그램에서 볼 수 있듯이.

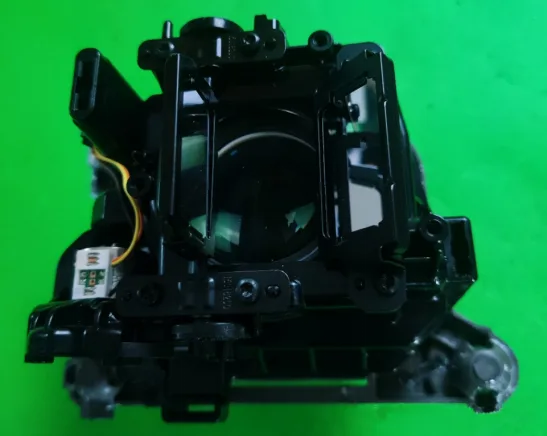

렌즈 기능 검토

전조등에서 세 렌즈의 기능을 상기: 가장 안쪽은 DLP입니다, 중간은 84 픽셀입니다, 그리고 가장 바깥 쪽은 저 빔 렌즈입니다.

낮은 빔 모듈

로우 빔 모듈에는 라디에이터의 기능을 통해 달성 된 컷오프 라인에 대한 저비용 솔루션을 제외하고는 특히 뛰어난 설계가 없습니다..

84-픽셀 렌즈

이 렌즈는 광원을 사용하여 직접 이미징 방법을 사용합니다.. 광원은 직접 이미징 렌즈가 이어집니다., 세 조각으로 디자인되었습니다: 유리, PMMI, 및 PC. 광원 픽셀의 정확한 배열은이 이미징 솔루션을 채택하는 데 중요합니다..

효과를위한 추가 렌즈

또 다른 값 비싼 설계 선택은 전체 조명 효과를 위해 모듈 앞에 추가 렌즈를 추가하는 것입니다..

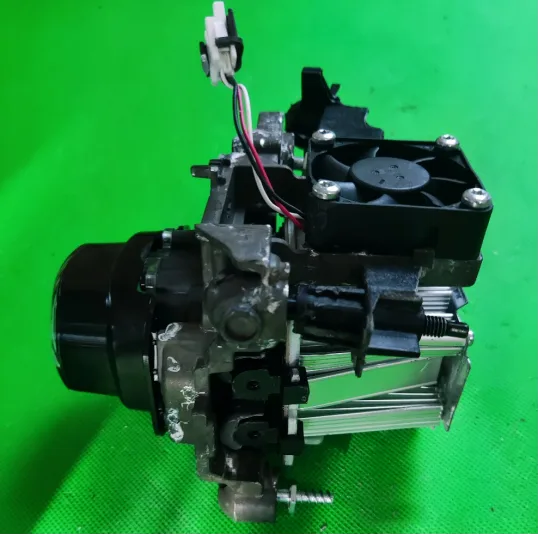

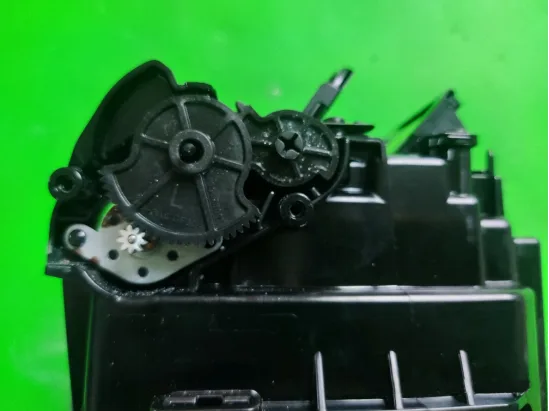

DLP 모듈 디자인

DLP 모듈에는 두 가지 흥미로운 디자인 기능이 있습니다: 외부 팬 디자인과 초 필드 투영을위한 디자인. DLP 모듈 (16*95*100) 라디에이터가 외부 장착됩니다, 냉각 팬이 라디에이터 뒷면에 직접 조립 된 상태에서. 이 디자인은 内置 디자인보다 더 나은 냉각을 제공합니다. 하지만, 이 외부 장착 팬이 추가 보호없이 가혹한 차량 환경을 견딜 수 있는지 여부는 여전히 남아 있습니다..

모듈 밀봉

모듈과 전체 램프는 설치 후 밀봉 및 조정 가능성을 모두 보장하기 위해 소프트 접착제로 밀봉됩니다.. 소프트 접착제는 2 개의 금속 압력판을 통해 램프 하우징 및 모듈 라디에이터에 고정됩니다..

초 필드 투영

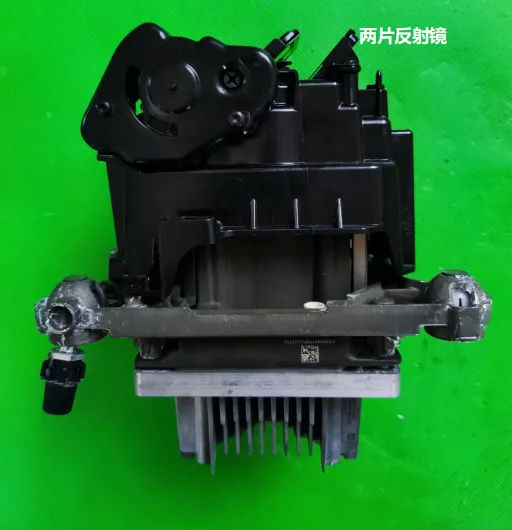

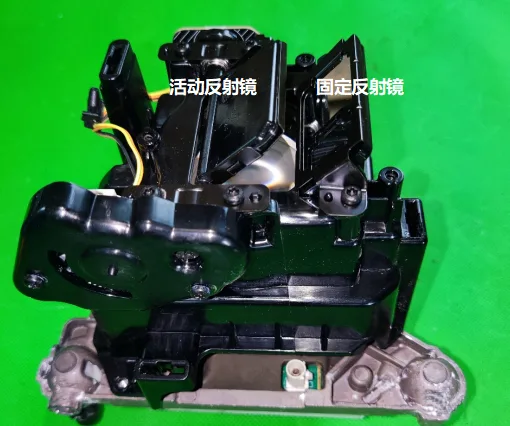

DLP 프로젝션 모듈 용, 투영 명확성을위한 시야 필드는 매우 크지 않습니다.. 그러므로, 로우 빔 기능과 초 필드 투영의 균형을 맞추려면 특수 설계가 필요합니다.. 가벼운 경로는 다음과 같습니다: 반사 미러는 각도를 변경하여 초 필드 투영을 가능하게합니다..

반사 미러 및 라디에이터

반사 미러는 모터를 통해 각도를 바꾸고 금속 클립으로 누르는 베어링을 통해 브래킷에 연결됩니다.. 라디에이터에는 3 개의 열 파이프가 있습니다.

결론

이것은 Aito M9 헤드 라이트에 대한 우리의 분해를 마무리합니다. 마지막으로, 이 헤드 라이트는 Xingyu에 의해 제조됩니다.

UGPCB 로고

UGPCB 로고