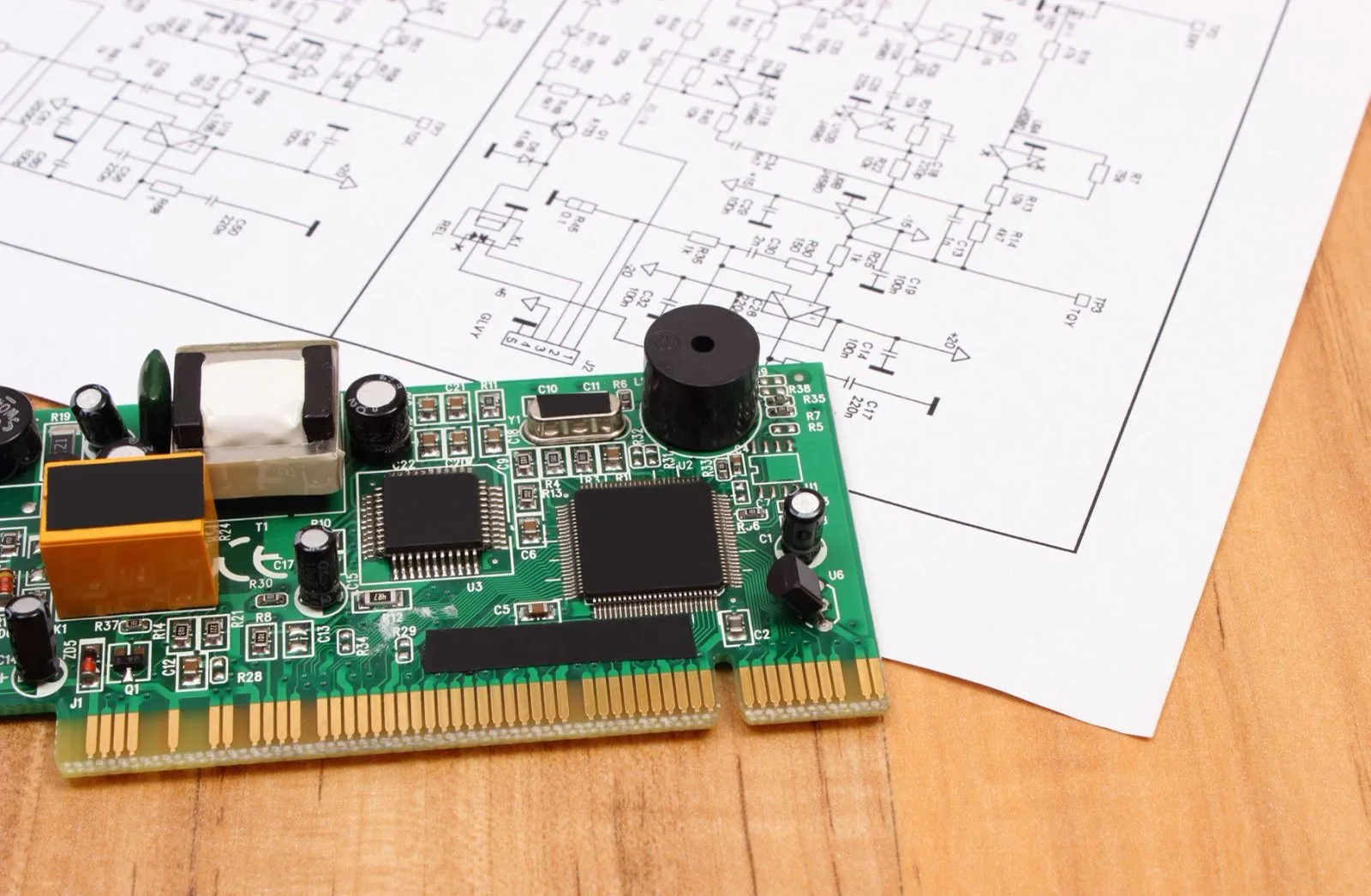

견고한 플렉스 PCB 설계

Rigid-Flex PCB 기술의 핵심 가치와 도전

Ridid-Flex PCBS는 단단하고 유연한 회로를 단일 구조로 통합합니다., 항공 우주에서 널리 사용됩니다, 의료기기, 가전제품, 자동차 시스템. 그들의 핵심 장점에는 포함됩니다:

- 공간 최적화: 3D 라우팅은 공간 사용량을 최대로 줄입니다 60%.

- 향상된 신뢰성: 실패 지점을 최소화하고 기계적 안정성을 향상시키기 위해 커넥터를 제거합니다..

- 신호 무결성: 고주파 신호 전송의 반사 및 손실을 줄입니다.

하지만, Ridid-Flex PCB 디자인은 독특한 과제를 제시합니다:

- 재료 호환성: 강성과 유연한 구역 간의 CTE 불일치는 스트레스 집중을 유발합니다..

- 굽힘 지구력: 동적 굽힘 영역은 견딜 수 있어야합니다 >100,000 사이클 (IPC-6013d 클래스 3 기준).

- 프로세스 복잡성: 다층 설계의 경우 ± 25 μm의 계층 간 정렬 정확도가 필요합니다..

전문 기능 매트릭스

1. 재료 선택 및 스택 업 디자인

- 유연한 기판: DuPont Pyralux® AP 및 Panasonic Megtron®과 같은 고성능 재료, 굽힘 반경을 낮게 달성합니다 0.5 mm.

- 단단한 기판: FR-4의 하이브리드 사용을 지원합니다, 높은 TG 재료, 로저스 고주파 라미네이트.

- 접착제 재료: 저 유량 Prepreg는 ± 5% 내에서 라미네이션 후 두께 균일 성을 보장합니다..

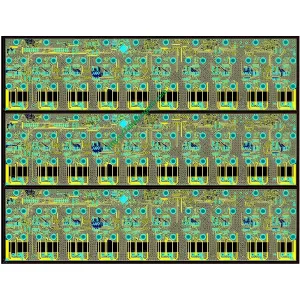

2. 정밀 라우팅 설계

- 유연한 영역 디자인:

- 최소 트레이스 폭/간격: 50 μm, 구리 두께: 12–35 μm.

- 응력 분포를 최적화하기위한 곡선 라우팅, 90 ° 각도를 피하십시오.

- 강성 구역 설계:

- 지원합니다 20+ 임피던스 제어 정확도가있는 층 HDI ± 5%.

- 차동 쌍 길이 일치하는 공차: ± 5 밀.

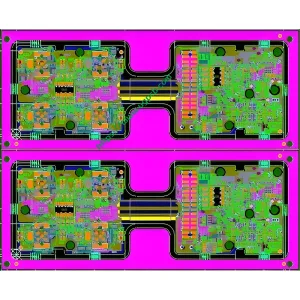

3. 굽힘 영역 최적화

- 굽힘 반경 계산: IPC-2223을 준수합니다 (동적 굽힘 반경 R ≥6t, 여기서 t는 총 플렉스 두께입니다).

- 강화 디자인: 기계적 강도를 향상시키기 위해 스테인레스 스틸 스티프너 또는 PI 커버 필름을 추가합니다..

- 스트레스 시뮬레이션: ANSYS 기계를 사용하여 피로 수명을 검증합니다.

4. 고출성 상호 연결 설계

- 강성 튀김 전이 구역: 계단식 윈도우 개방 설계는 스트레스 농도를 방지합니다.

- 기술을 통해 맹인/매장: 레이저 드릴링 정확도 ± 15 μm, 지원 0.1 mm microvias.

- 표면 마감: 옵션에는 Enig가 포함됩니다, 침수 금, 다양한 응용에 대한 OSP.

전체 프로세스 기술 지원 시스템

설계 검증 단계

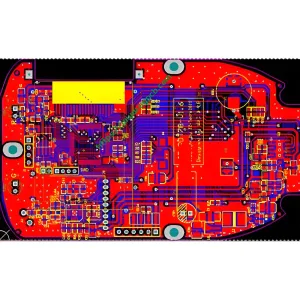

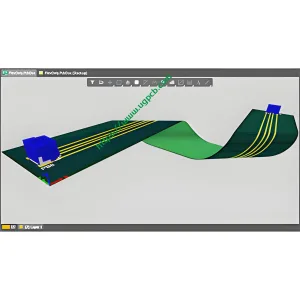

- 3D 모델링 & 시뮬레이션: Cadence Allegro 및 Mentor Xpedition으로 라우팅을 최적화합니다.

- 열 분석: Flotherm®을 사용하여 열 분포를 검증합니다.

- 기계적 스트레스 테스트: 테스트 중지 (-55℃ ~ 150 0 사이클링, 20G 진동).

제조 공정 제어

- 레이저 절단: 플렉스 영역 윤곽 정확도 ± 50 μm.

- 진공 라미네이션: 강성 층과 플렉스 층 사이의 기포가없는 결합을 보장합니다.

- AOI 검사: 100% 결함 감지 속도로 자동화 된 광학 검사 >99.9%.

테스트 & 인증

- 전기 테스트: 4-와이어 임피던스 테스트 및 TDR 결함 현지화.

- 벤드 사이클 테스트: 초과 100,000 동적 굽힘 (IPC-6013d 클래스 3).

- 환경 신뢰성 테스트: 1,000 85 ℃/85% RH에서 시간.

일반적인 응용 프로그램 시나리오

- 항공우주: IPC-6013DS 우주 등급 표준을 준수하는 위성 배치 가능한 안테나 및 항공 전자 시스템.

- 의료 기기: 내시경 및 웨어러블 지원 >10,000 동적 굽힘.

- 가전제품: 접이식 스마트 폰 및 벤드 반경이있는 AR/VR 장치 1 mm.

- 자동차 전자: AEC-Q200 표준을 충족하는 ADA 및 차량 내 카메라.

서비스 모델 & 기술 지원

- 빠른 프로토 타이핑: 8 층 RIDID-FLEX PCB 샘플을 전달합니다 72 시간.

- 디자인 검토 서비스: 제조 가능성 최적화를위한 DFM/DFA 보고서를 제공합니다.

- 실패 분석 실험실: 단면 분석 및 SEM/EDS 재료 테스트를 제공합니다.

- 인증 지원: ISO 9001/IATF 16949 군용 NADCAP 인증으로 인증.

개념에서 대량 생산에 이르기까지

10 년이 넘는 Rigid-Flex PCB 전문 지식, 150+ 성공적인 프로젝트, 우리는 지능적입니다, 혁신적인 제품을위한 고 신뢰성 솔루션.

지금 PCB 전문가 팀에 문의하여 맞춤형 디자인 평가 보고서를 얻으십시오.!

UGPCB 로고

UGPCB 로고

위챗

WeChat으로 QR 코드를 스캔하세요