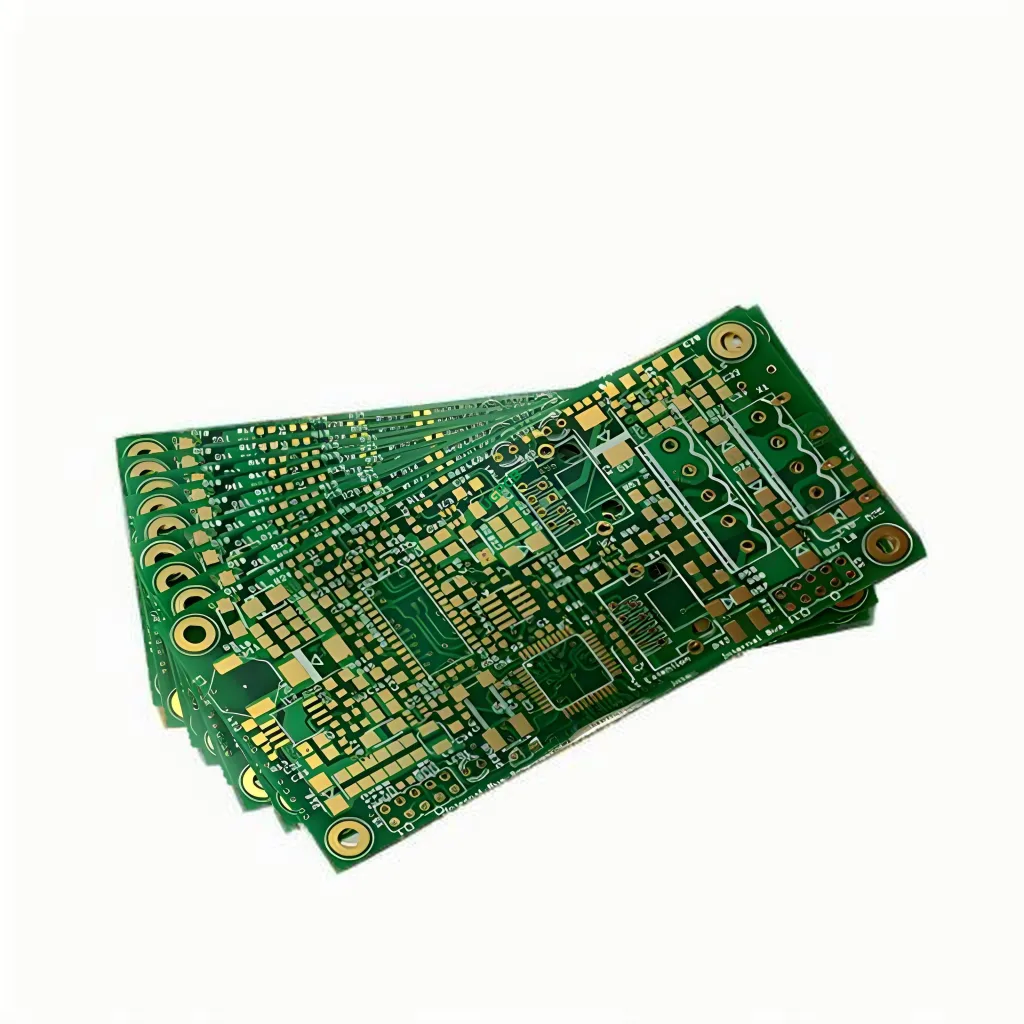

What is a 10Layers ENIG Board?

A 10-layer ENIG (무전해 니켈 침지 금) board is an advanced multilayer printed circuit board (PCB) with ten layers of conductive material, typically copper, separated by insulating layers. 그만큼 “동의하다” refers to the surface treatment applied to the copper traces, which involves electroless nickel and immersion gold plating. This type of PCB is designed for high-density and complex electronic applications.

설계 요구 사항

Designing a 10-layer ENIG board involves several key considerations:

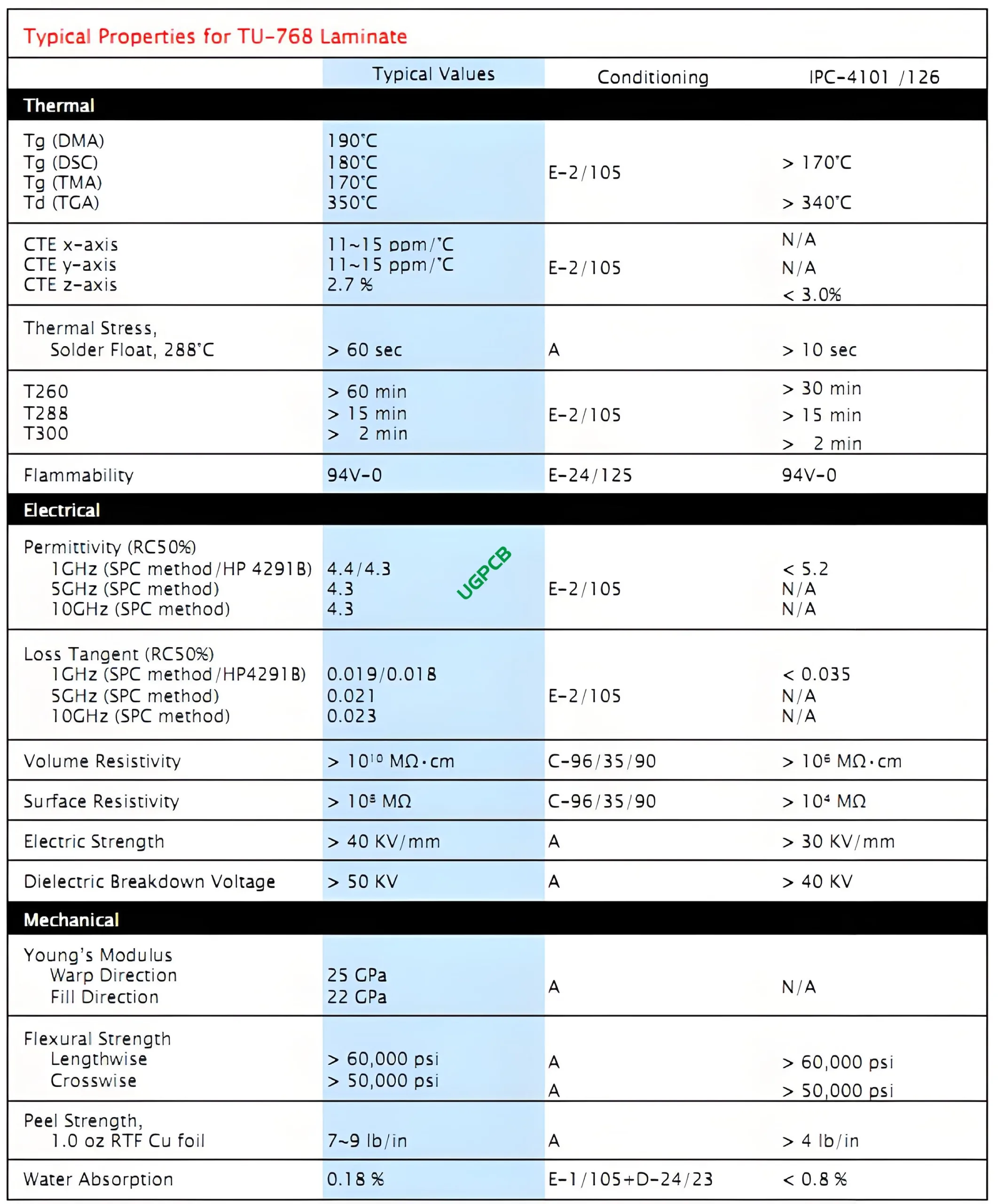

- 재료: Made from TU-768, a high-performance composite material known for its excellent electrical properties and durability.

- 레이어 수: Consists of ten layers, allowing for intricate and dense circuit designs.

- 구리 두께: Ranges from 2OZ to 3OZ, providing robust conductivity for high-power applications.

- 표면 처리: Features immersion gold plating, which offers excellent solderability and corrosion resistance.

- 추적과 공간: Minimum trace and space are set at 3mil (0.075mm), enabling fine details in the circuit design.

How Does it Work?

The 10-layer ENIG board functions by providing multiple layers of conductive pathways, separated by insulating layers, to interconnect electronic components. The immersion gold surface treatment ensures reliable soldering and long-term protection against oxidation and wear.

응용

Due to their complexity and reliability, 10-layer ENIG boards are widely used in various high-end electronic applications including:

- 항공 우주 및 방어 시스템

- 고속 네트워킹 장비

- Advanced telecommunication devices

- 의료영상장비

분류

10-layer ENIG boards can be classified based on several factors:

- By Material: Most commonly made from TU-768 due to its balance of cost, 힘, 및 전기 특성.

- By Copper Thickness: Varies from lightweight (2온스) to heavyweight (3온스) depending on the application’s needs.

- By Surface Treatment: Features immersion gold plating, which provides excellent solderability and corrosion resistance.

Materials Used

The primary materials used in manufacturing 10-layer ENIG boards include:

- TU-768: A glass-reinforced epoxy laminate that provides excellent mechanical strength and thermal stability.

- 구리: Used for the conductive layers, with thickness varying based on design requirements.

- 솔더 마스크: Typically green or white, it protects the copper traces from oxidation and accidental short circuits.

- 이머젼 골드: Applied as a surface treatment to improve solderability and protect against corrosion.

성능 특성

Key performance attributes of a 10-layer ENIG board include:

- 고밀도: Allows for more components to be packed into a smaller area.

- 신뢰할 수 있음: The use of multiple layers reduces the risk of electrical shorts and improves signal integrity.

- 신호 무결성: Improved due to shorter signal paths and reduced crosstalk.

Structural Composition

구조적으로, a 10-layer ENIG board comprises:

- Conductive Layers: Made of copper, etched into the desired circuit patterns.

- Insulating Layers: Prevent electrical shorts between conductive layers.

- Plated Through-Hole Vias: Facilitate connections between different layers.

독특한 특징

Some notable features of a 10-layer ENIG board are:

- Fine Pitch: Allows for high-density interconnects making it ideal for compact devices.

- Robustness: The use of multiple layers provides a strong mechanical bond between the board and components.

- 다재: Suitable for a wide range of applications due to customizable layer counts and material choices.

생산 과정

The manufacturing process of a 10-layer ENIG board involves several steps:

- 디자인 및 레이아웃: Using specialized software to create the circuit pattern.

- 재료 준비: Cutting base materials to size and cleaning surfaces.

- 라미네이션: Stacking and bonding individual layers under heat and pressure.

- 에칭: Removing excess copper to form the desired circuit paths.

- 도금: Adding a thin layer of metal to vias and exposed copper areas.

- 솔더 마스크 적용: Applying the green or white coating to protect traces.

- 표면 처리: Applying immersion gold for solderability and corrosion resistance.

- 최종검사: Ensuring quality and functionality before shipment.

사용 사례

Common scenarios where a 10-layer ENIG board might be employed include:

- High-density interconnect applications in aerospace and defense systems.

- Advanced communication systems requiring low signal loss.

- Portable medical instruments needing reliable performance in harsh environments.

- Automotive electronics demanding robustness and longevity.

요약하면, the 10-layer ENIG board represents a significant advancement in printed circuit board technology offering unparalleled complexity and performance for modern electronic applications Its design flexibility combined with superior signal integrity and durability makes it an essential component in the development of next-generation high-end electronics and beyond

UGPCB 로고

UGPCB 로고