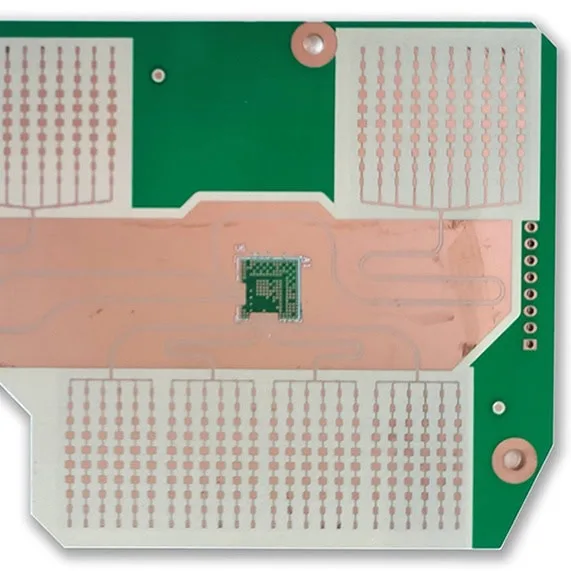

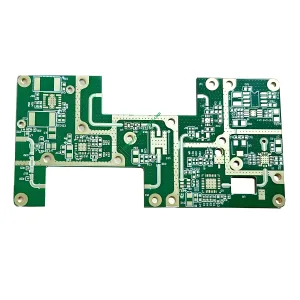

RO3003 Ceramic Hybrid High Frequency PCB Overview

The RO3003 Ceramic Hybrid High Frequency PCB is a premium printed circuit board designed specifically for high-frequency applications. It combines the advanced electrical properties of Rogers RO3003 material with the cost-effectiveness and versatility of FR4, creating a robust and reliable substrate. This PCB is ideal for guided wave radar level gauges (GWRLGs) 및 기타 고성능 응용 프로그램.

재료 구성

The RO3003 Ceramic Hybrid High Frequency PCB is crafted from a unique blend of Rogers RO3003 and FR4 mixed dielectric materials. This combination offers a balance of electrical performance, 비용, 신뢰성, making it suitable for a wide range of high-frequency applications.

성능 특성

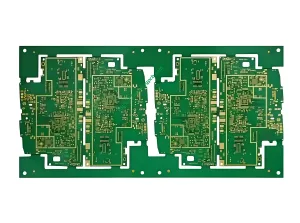

- 레이어 수: The PCB features a 6-layer design, providing ample space for complex circuitry and components.

- 유전 상수 (D k): With a D K of 3.00 ± 0.04, the board exhibits consistent electrical performance across a wide frequency range.

- 완성된 두께: PCB의 마감 두께는 2.0mm입니다., ensuring durability and structural integrity.

- 구리 두께: The 1oz copper thickness offers excellent conductivity and current carrying capacity.

- 유전체 두께: The dielectric layer is 0.762mm thick, contributing to the board’s overall electrical performance.

- 열전도율: With a thermal conductivity of 0.43w/m.k, the PCB effectively manages heat dissipation, preventing overheating and component failure.

- 가연성: The board meets the 94V-0 가연성 등급, ensuring safety in various environments.

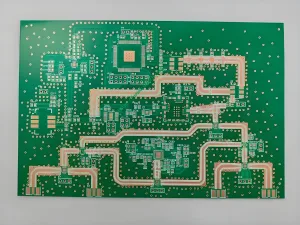

- 표면 처리: The immersion gold surface treatment enhances conductivity and corrosion resistance, ensuring reliable performance over time.

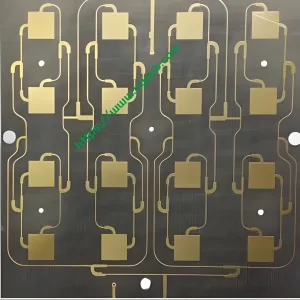

생산 과정

The production of RO3003 Ceramic Hybrid High Frequency PCBs involves several precision steps:

- 재료 준비: Rogers RO3003 and FR4 materials are carefully selected and prepared for mixing.

- Mixing and Laminating: The materials are blended and laminated together under controlled conditions to form a uniform substrate.

- 회로 설계 및 레이아웃: 원하는 회로 패턴은 고급 CAD 소프트웨어를 사용하여 설계 및 배치됩니다..

- 조작: PCB는 에칭을 포함한 일련의 프로세스를 통해 제조됩니다., 교련, 그리고 구리 도금.

- 표면 처리: 이사회는 전도도 및 부식 저항을 향상시키기 위해 침수 금 표면 처리를 거칩니다..

- 품질 관리: 각 PCB는 지정된 성능 표준을 충족하도록 엄격한 테스트를 거칩니다..

응용 시나리오

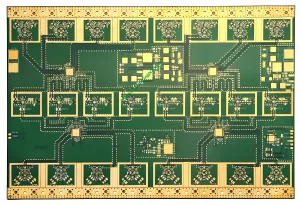

The RO3003 Ceramic Hybrid High Frequency PCB is ideal for use in guided wave radar level gauges (GWRLGs), where high-frequency performance and reliability are critical. The PCB’s exceptional electrical properties and robust design make it suitable for the following applications:

- High-Frequency Signal Transmission: The PCB supports high-frequency signal transmission with minimal loss, ensuring accurate and reliable level measurement.

- Complex Circuitry: The 6-layer design provides ample space for complex circuitry and components, enabling advanced functionality and performance.

- Harsh Environments: The PCB’s durability and flame resistance make it suitable for use in harsh environments, ensuring reliable performance even in challenging conditions.

요약하면, the RO3003 Ceramic Hybrid High Frequency PCB is a versatile and high-performance solution for guided wave radar level gauges and other high-frequency applications. Its combination of electrical excellence, 내구성, 신뢰성은 응용 프로그램을 요구하기위한 이상적인 선택입니다..

UGPCB 로고

UGPCB 로고