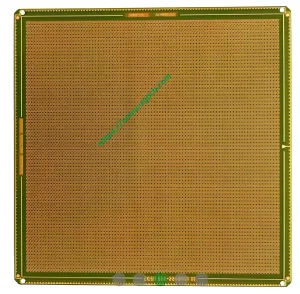

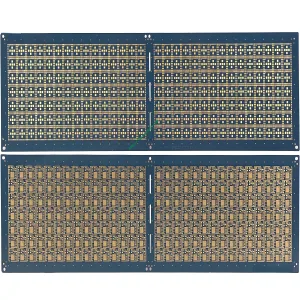

1. 마이크로 서빙 기술은 30UM/30UM 라인/공간을 실현합니다

2. 레이저 형성 기술을 통한 소규모 직경은 고밀도 배선을 실현합니다.

3. 탁월한 신뢰성을 가진 열 세팅 합성 수지를 사용하십시오

4. 해당 표면 처리 (/또는, SAC 납땜, 등) 포장 요구 사항에 따라 구현할 수 있습니다

5. 무연 및 불소가없는 녹색 제품을 제공 할 수 있습니다.

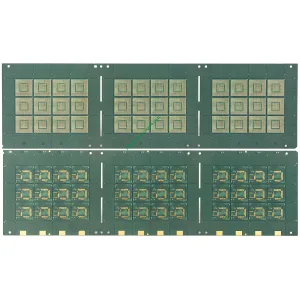

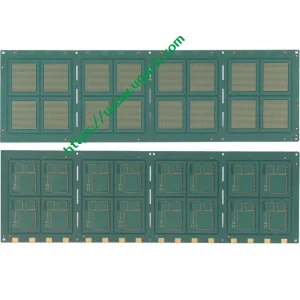

BGA와 같은 새로운 IC의 활발한 개발로 (볼 그리드 어레이) 및 CSP (칩 스케일 포장), IC 기판이 호황을 누리고 있습니다, 그리고이 IC는 새로운 포장 캐리어가 필요합니다. 가장 진보 된 PCB 중 하나입니다 (인쇄 회로 기판), IC 기판 PCB, 모든 레이어 HDI PCB 및 유연한 강성 PCB와 함께, 인기와 응용 분야에서 폭발적인 성장이 있습니다, 이제 통신 및 전자 업데이트에 널리 사용됩니다..

IC 기판은 베어 IC를 패키지하는 데 사용되는 기판입니다. (집적 회로) 작은 조각. 칩 및 회로 보드 연결, IC는 다음 기능을 갖춘 중간 제품입니다:

• 반도체 IC 칩을 캡처합니다;

• 칩과 PCB를 연결하기위한 내부 배선;

• 보호 할 수 있습니다, IC 칩 강화 및 지원 및 열 소산 터널 제공.

IC 기판 분류

에이. 패키지 유형별로 분류됩니다

• BGA IC 기판. 이 IC 기판은 열 소산 및 전기 성능 측면에서 잘 수행됩니다., 칩 핀을 크게 증가시킬 수 있습니다. 그러므로, 더 많은 IC 패키지에 적합합니다 300 다리.

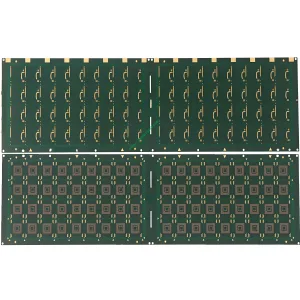

• CSP IC 기판. CSP는 단일 칩 패키지입니다, 가벼운 무게, 작은 크기, IC와 비슷한 크기. CSP IC 기판은 주로 메모리 제품에 사용됩니다, 적은 수의 핀이있는 통신 제품 및 전자 제품.

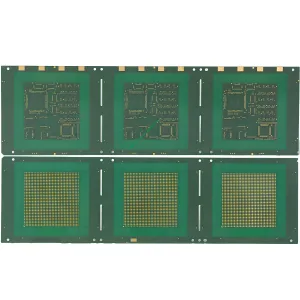

• FC IC 기판. FC (플립 칩) 칩을 뒤집는 패키지입니다, 신호 간섭이 낮습니다, 낮은 회로 손실, 우수한 성능과 효과적인 열 소산.

• MCM IC 기판. MCM은 다중 치프 모듈의 약어입니다. 이 유형의 IC 기판은 다른 기능을 가진 칩을 하나의 패키지로 흡수합니다.. 그러므로, 가벼움을 포함한 특성으로 인해, 얇음, 단락과 소형화, 이 제품은 최상의 솔루션이 될 수 있습니다. 물론, 여러 칩이 하나의 패키지로 포장되므로, 이 유형의 기판은 신호 간섭 측면에서 잘 작동하지 않습니다., 열 방출, 그리고 미세 배선.

비. 재료 특성으로 분류됩니다

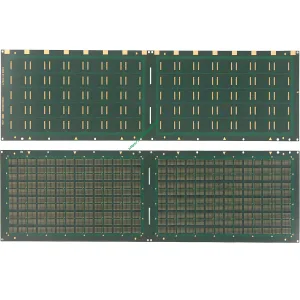

• 강성 IC 기판. 주로 에폭시 수지로 만들어졌습니다, BT 수지 또는 ABF 수지. CTE (열 팽창 계수) 약 13 에게 17 ppm/°C. • IC 기판. 주로 PI 또는 PE 수지로 만들어졌으며 CTE가 있습니다. 13 27ppm/° C • 세라믹 IC 기판. 주로 세라믹 재료로 만들어졌습니다, 산화 알루미늄과 같은, 질화증 또는 실리콘 카바이드 알루미늄. CTE는 비교적 낮습니다, ~에 대한 6 8ppm/° C

기음. 본딩 기술에 의한 분류

• 와이어 본딩

•꼬리표 (자동 키보드 키잉)

• FC 본딩

IC 기판 PCB의 적용

IC 기판 PCB는 주로 가벼운 중간에 사용됩니다, 가벼운 중간 및 강력한 전자 제품, 스마트 폰과 같은, 노트북 컴퓨터, 태블릿 컴퓨터 및 네트워크, 통신과 같은, 의료, 산업 제어, 항공 우주 및 군사 분야.

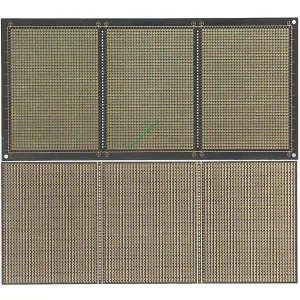

강성 PCB는 다층 PCB를 통과합니다, 전통적인 HDI PCB, SLP (기판 유사 PCB) IC의 일련의 혁신적인 기판 PCB. SLP는 단단한 PCB입니다, 그리고 제조 공정은 반도체 규모와 유사합니다..

IC 기판 PCB 제조의 어려움

표준 PCB와 비교합니다, IC 기판은 제조의 고성능 및 고급 기능의 어려움을 극복해야합니다..

IC 기판은 얇고 쉽게 변형됩니다, 특히 보드의 두께가 0.2 mm. 이 어려움을 극복합니다, 획기적인 것은 보드 수축으로 이루어져야합니다, 기질 휘파이 및 라미네이션 두께를 효과적으로 제어하기위한 라미네이션 파라미터 및 층 포지셔닝 시스템.

UGPCB 로고

UGPCB 로고