Burn-In Board 개요

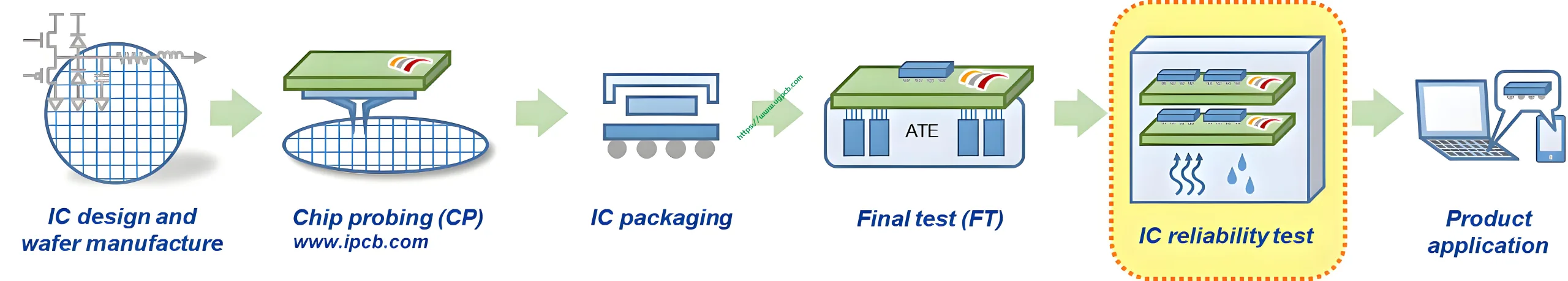

Burn-In Board는 특수 유형의 PCB입니다 (인쇄 회로 기판) IC Burn-In Test 응용 프로그램을 위해 설계되었습니다, 턱받이라고도합니다 (번인 보드) PCB. 통합 회로의 신뢰성과 수명을 보장하기 위해 엄격한 테스트를 거칩니다. (ICS) 전자 장치에 배치되기 전에.

Burn-In Board의 목적

Burn-In Board의 주요 목적은 잠재적 조기 장애를 식별하기 위해 IC를 노화 조건에 따라 적용하는 것입니다.. 이 프로세스는 결함이있는 구성 요소가 더 큰 시스템에 통합되기 전에 필터링하는 데 도움이됩니다., 따라서 전체 실패율을 줄이고 제품 품질 향상.

Burn-In Board의 분류

번인 보드는 레이어 수와 같은 다양한 요소를 기반으로 분류 할 수 있습니다., 사용 된 자료, 크기, 및 특정 응용 프로그램 요구 사항. 우리의 Burn-In Board, 예를 들어, IC Burn-In Tests를 위해 특별히 설계된 20 층 PCB입니다..

재료 구성

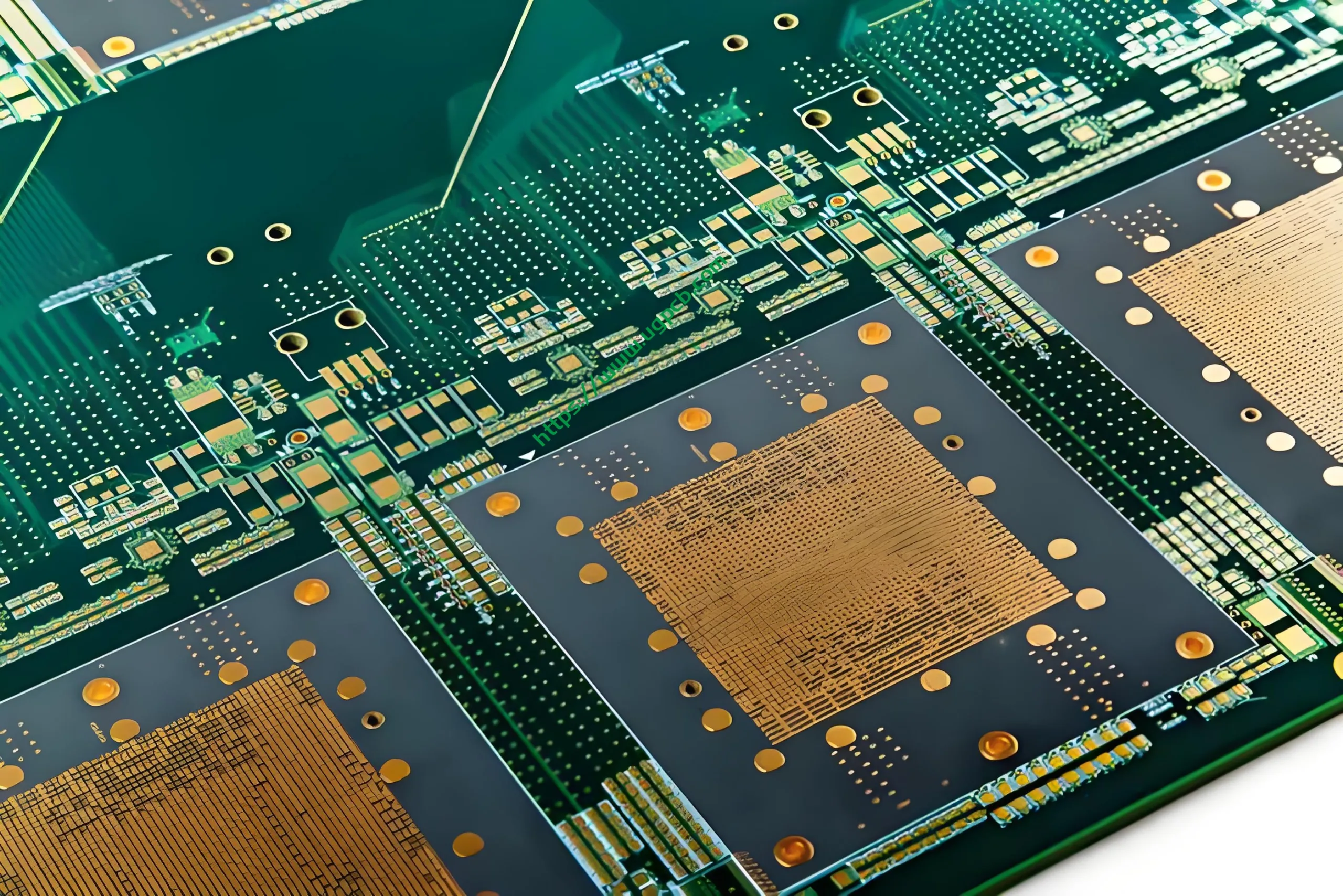

Burn-In Board는 높은 TG TG175 재료를 사용하여 제조됩니다., 유리 전이 온도가 높습니다. 이 재료는 보드가 구조적 무결성을 손상시키지 않고 화상 공정에서 더 높은 온도를 견딜 수 있도록합니다..

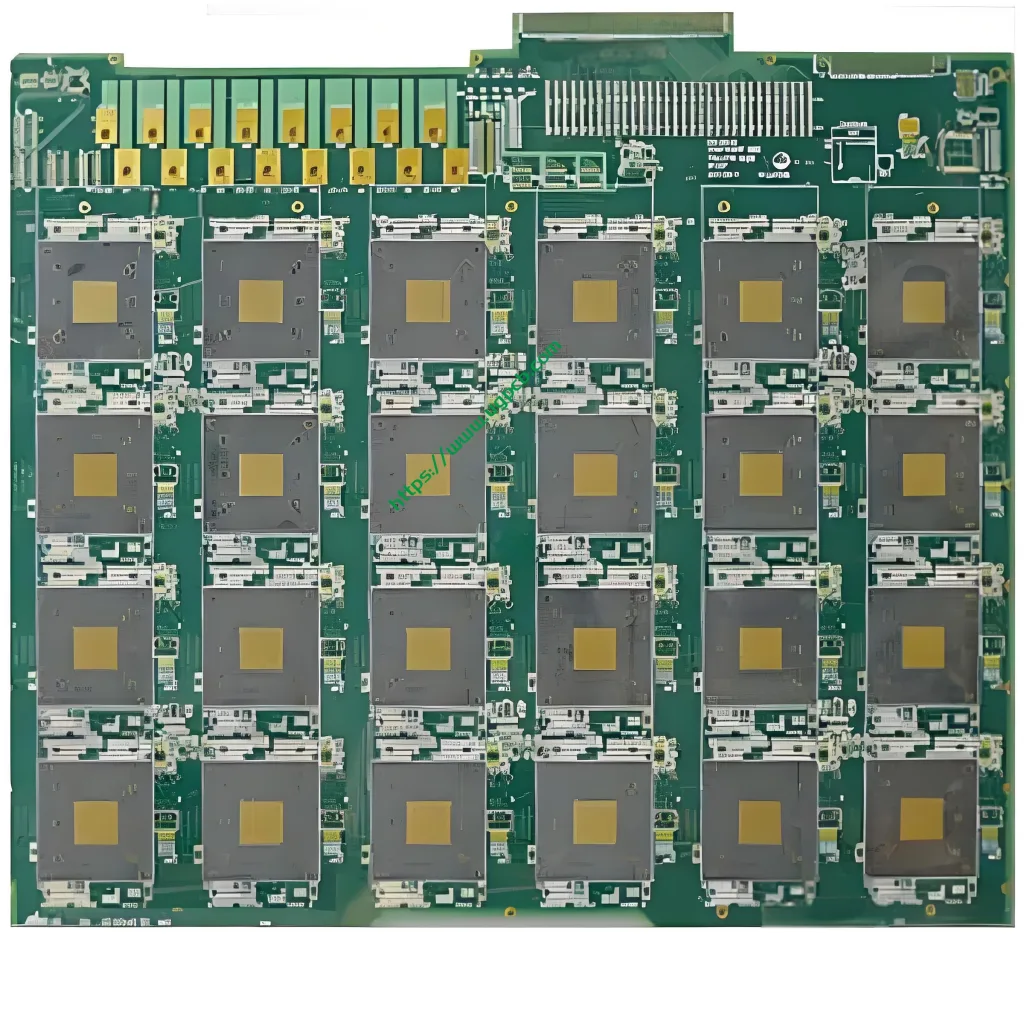

성능 사양

Burn-In Board는 인상적인 성능 사양을 자랑합니다, 보드 두께 3.2mm를 포함합니다, 크기 610 * 572mm, 그리고 BGA 번호의 수 24. 그것은 몰입 금 표면 기술을 특징으로합니다 (3유) 향상된 전도도 및 부식 저항. 구리 두께는 내부 및 외부 층 모두에 최적화됩니다., 내부 층의 경우 70/35UM, 외부 층의 경우 35UM.

구조 설계

Burn-In Board의 구조 설계는 IC Burn-In Testing의 엄격한 요구를 충족하도록 조정되었습니다.. 20 층 구조는 충분한 라우팅 공간과 전기 분리를 제공합니다., 테스트 중 신뢰할 수있는 성능을 보장합니다. 보드의 녹색은 육안 검사 및 식별에 도움이됩니다..

주요 특징

Burn-In Board의 주목할만한 기능 중 일부에는 높은 TG 재료가 포함됩니다., 더 높은 온도 작동을 허용합니다, 그리고 침지 금 표면 마감, 이는 전기 접촉 및 부식 저항을 탁월합니다. 추가적으로, 이사회의 디자인은 많은 수의 BGA 구성 요소를 지원합니다., 복잡한 IC 테스트 응용 프로그램에 적합합니다.

생산 과정

Burn-In 보드의 생산에는 여러 단계가 포함됩니다, 원료 준비를 포함하여, 라미네이션, 교련, 구리 도금, 에칭, 표면 마감 적용. 품질 표준 및 고객 사양을 준수하기 위해 각 단계가 신중하게 모니터링됩니다.. 생산 후, 이사회는 성능과 신뢰성을 확인하기 위해 엄격한 테스트를 거칩니다..

응용 시나리오

번인 보드는 전자 산업에서 널리 사용됩니다, 특히 IC의 제조 및 테스트에서. 그들은 고출성 전자 장치를 생산하는 회사에 필수적입니다., 자동차와 같은, 항공우주, 의료 장비 제조업체. 번인 보드를 사용하여, 이 회사들은 시장에 도달하기 전에 제품의 품질과 신뢰성을 보장 할 수 있습니다..

UGPCB 로고

UGPCB 로고