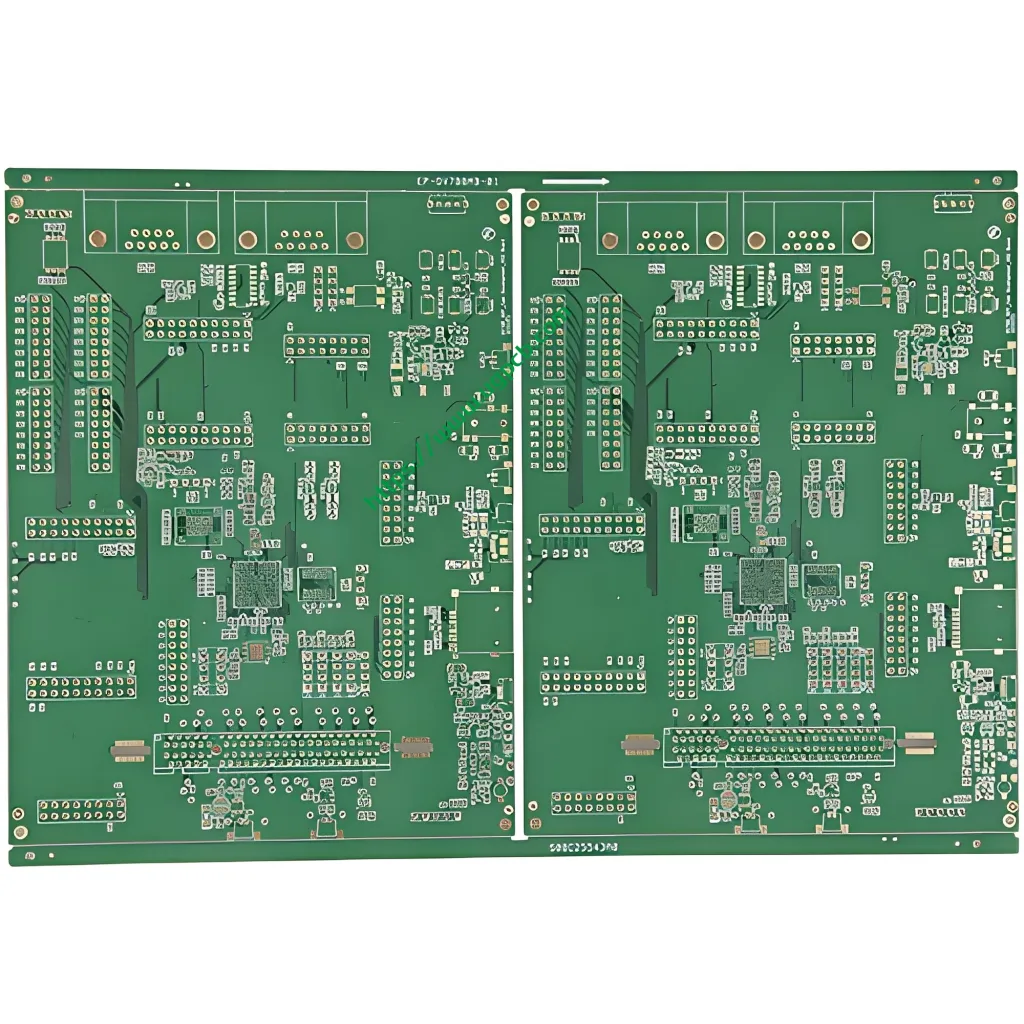

HDI PCB의 정의

고밀도 상호 연결 (HDI) 가장 작은 발자국에서 더 많은 수의 상호 연결이있는 PCB입니다.. 이것은 회로 보드의 소형화로 이어집니다. 구성 요소가 더 가깝게 배치되고 보드 공간이 크게 줄어 듭니다., 그러나 기능은 손상되지 않습니다.

Characteristics of HDI PCB

더 정확하게, 평균이있는 PCB 120 에게 160 제곱 인치당 핀은 HDI PCB로 간주됩니다. HDI 설계는 조밀 한 구성 요소 배치와 다목적 라우팅을 결합합니다. HDI popularized microporous technology, creating denser circuits by implementing microvias, 묻힌 vias, 그리고 맹인 비아. 구리 드릴링 감소는 HDI 설계의 특징입니다..

HDI PCB의 장점

특별한 다목적 성

HDI 보드는 무게가 이상적입니다, 공간, 신뢰할 수 있음, 성능이 주요 관심사입니다.

소형 디자인

블라인드의 조합, 매장, Micro Vias는 보드 공간 요구 사항을 줄입니다.

더 나은 신호 무결성

HDI는 기술을 통해 비아 패드 및 블라인드를 사용합니다. 이것은 구성 요소를 서로 가깝게 유지하는 데 도움이됩니다, 신호 경로 길이 감소. HDI 기술은 통과 홀 스텁을 제거합니다, 따라서 신호 반사를 줄입니다, 따라서 신호 품질을 향상시킵니다. 그러므로, 더 짧은 신호 경로로 인해 신호 무결성을 크게 향상시킵니다..

높은 신뢰성

쌓인 VIAS의 구현은이 보드가 극한 환경 조건에 대한 슈퍼 장벽으로 만듭니다..

비용 효율적입니다

표준 8 계층 통계 구멍 보드의 기능 (표준 PCB) can be reduced to a 6-layer HDI board without compromising the quality. This makes HDI PCBs a cost-effective solution.

UGPCB 로고

UGPCB 로고