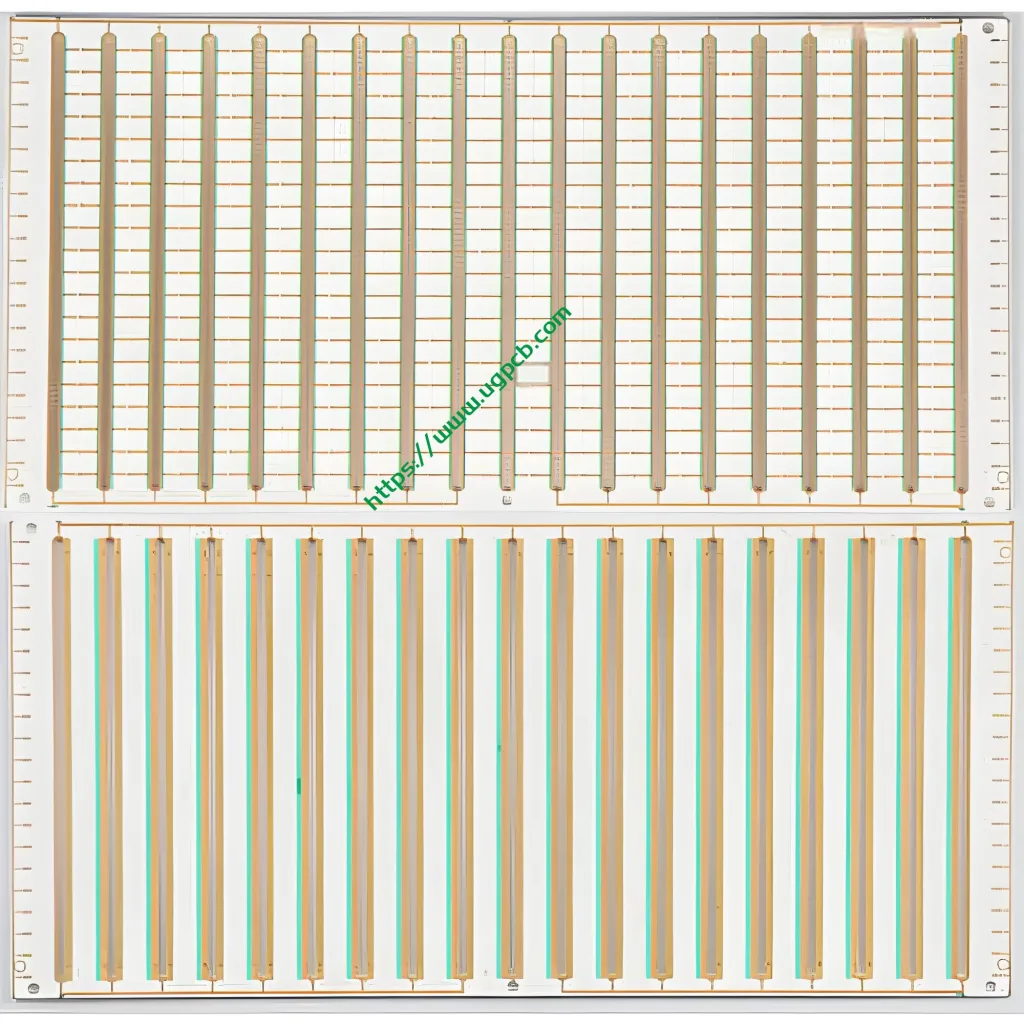

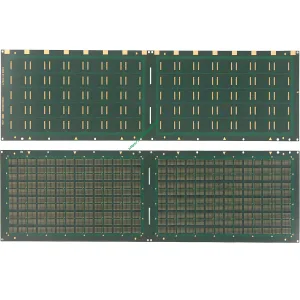

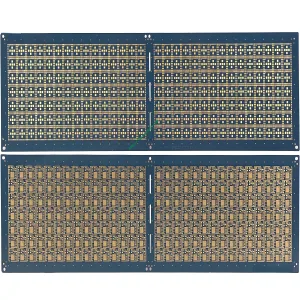

반도체 성분 및 PCB를 제조하기위한 기판 재료

성분 기판 PCB에 사용되는 기판 재료는 반도체 구성 요소 및 인쇄 회로 보드를 제조하는 기본 재료입니다., 실리콘과 같은, 갈륨 아르 세 나이드, 반도체 산업에 사용 된 실리콘 에피 택셜 가넷. 주요 원료로 고순도 알루미나로 만들어졌습니다., 이는 고압 성형에 의해 형성됩니다, 고온 발사, 그리고 자르고 연마했습니다. 세라믹 기판은 두꺼운 필름 및 박막 회로를 제조하는 기본 재료입니다.. 구리 클래드 라미네이트 (클래드 라미네이트라고합니다) 인쇄 회로 보드를 제조하는 데 사용되는 기판 재료입니다.. 다양한 구성 요소를 지원하는 것 외에도, 또한 전기 연결 또는 전기 절연을 달성 할 수 있습니다..

전자 포장에서 포장 기판의 역할

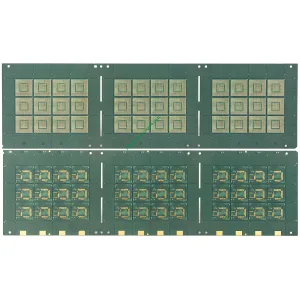

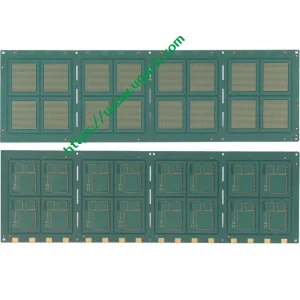

포장 기판은 전자 포장의 중요한 부분이며 칩과 외부 회로 사이의 다리입니다.. 기판은 패키지에서 다음과 같은 역할을합니다:

- 칩과 외부 세계 사이의 전류와 신호의 전송을 실현하십시오..

- 칩을 기계적으로 보호하고 지원합니다.

- 칩이 외부 세계에 열을 소비하는 주요 방법입니다..

- 칩과 외부 회로 사이의 공간 전환입니다..

물질적 관점에서, 일반적으로 사용되는 포장 기판에는 금속 기판이 포함됩니다, 세라믹 기판, 및 유기 기질.

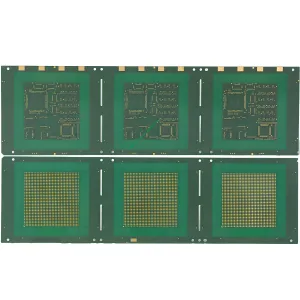

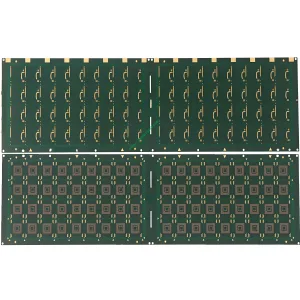

금속 기판: 속성 및 응용 프로그램

금속 기판은 금속 시트로 만든 금속 기반 구리 클래드 라미네이트를 나타냅니다., 절연 유전체 층, 그리고 구리 포일 복합재. 금속 기판은 탁월한 열 소산 성능으로 인해 전자 부품 및 통합 회로지지 재료 및 방열판에 널리 사용됩니다., 기계식 처리 성능, 전자기 차폐 성능, 치수 안정성 성능, 자기 성능, 그리고 다양성. 전력 전자 장치 (정류기 튜브와 같은, 사이리스터, 전원 모듈, 레이저 다이오드, 마이크로파 튜브, 등.) 및 미세 전자 장치 (컴퓨터 CPU와 같은, DSP 칩) 전자 레인지 통신 분야에서 중요한 역할을합니다., 자동 제어, 전력 변환, 항공 우주.

전통 및 현재 금속 기반 전자 포장 재료

전통적인 금속 기반 전자 포장재에는 침략이 포함됩니다, 잡지, w, 모, 알, Cu, 등. 이 재료는 위에서 언급 한 요구 사항을 부분적으로 충족시킬 수 있습니다, 그러나 여전히 많은 단점이 있습니다. 침략자는 철 코발트-니켈 합금입니다, 그리고 Kovar는 Iron-Nickel 합금입니다. 그들은 좋은 처리 속성을 가지고 있습니다, 낮은 열 팽창 계수, 그러나 열전도율이 좋지 않습니다; Mo와 W는 열 팽창 계수가 낮습니다, 열전도율은 침대와 코바보다 훨씬 높습니다., 그리고 힘과 경도는 매우 높습니다, 그래서 Mo와 W는 전력 반도체 산업에서 널리 사용되었습니다..

하지만, Mo와 W는 비싸다, 처리하기 어렵습니다, 납땜이 가난합니다, 밀도가 높습니다, 순수한 Cu보다 열전도율이 훨씬 낮습니다, 추가 응용 프로그램을 제한합니다. Cu와 Al은 우수한 열 및 전기 전도성을 가지고 있습니다, 그러나 열 팽창 계수는 너무 큽니다, 열 응력이 발생하기 쉽습니다. 현재의 금속 기판은 금속 시트로 만든 금속 기반 구리 클래드 라미네이트를 나타냅니다., 절연 유전체 층, 그리고 구리 (또는 알루미늄) 포일 복합재.

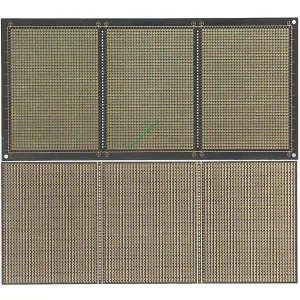

구성 요소 기판 PCB를위한 기판 재료를 선택할 때 고려해야 할 요소

성분 기판 PCB에 대한 기판 재료의 선택은 먼저 기판 재료의 전기적 특성을 고려해야합니다., 즉, 단열 저항, 아크 저항, 및 기판의 파괴 강도; 둘째로, 기계적 특성을 고려하십시오, 즉, 인쇄 회로 보드의 전단 강도 및 경도. 게다가, 가격 및 PCB 제조 비용을 고려해야합니다.

UGPCB 로고

UGPCB 로고