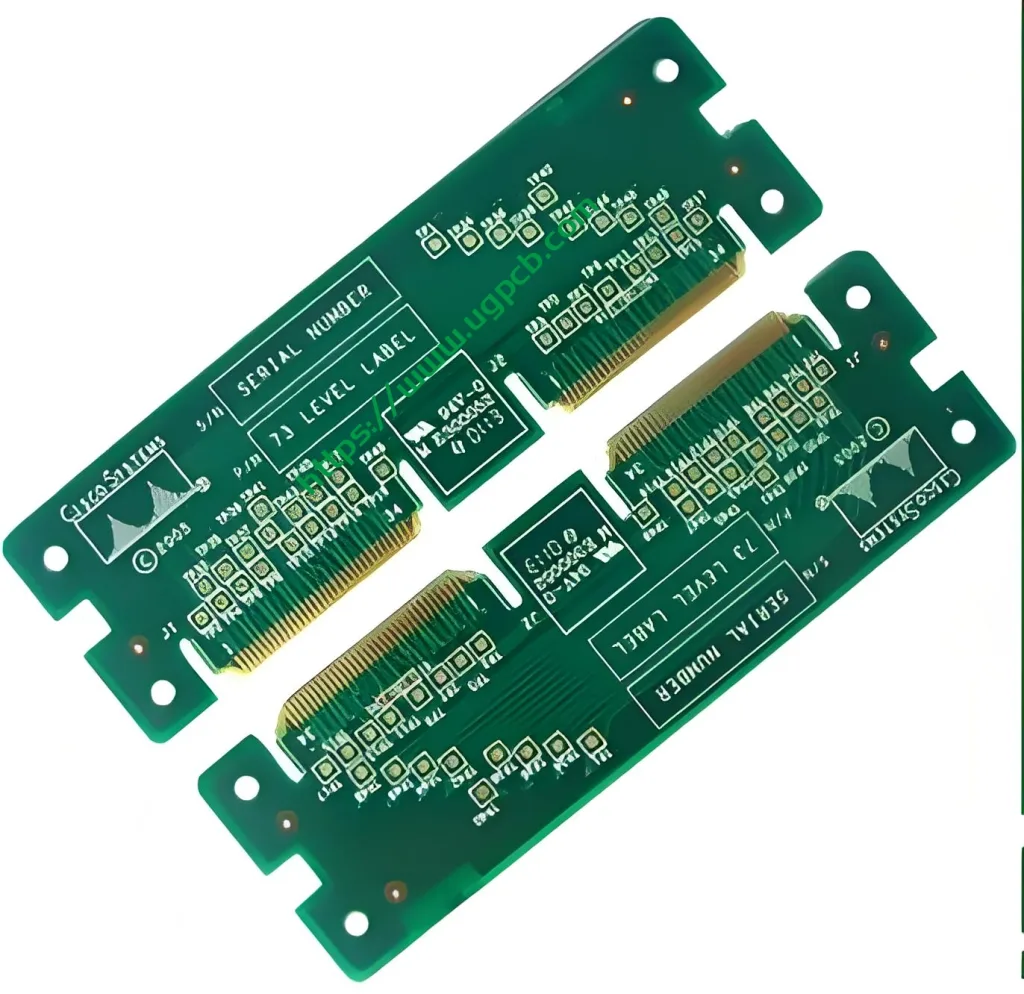

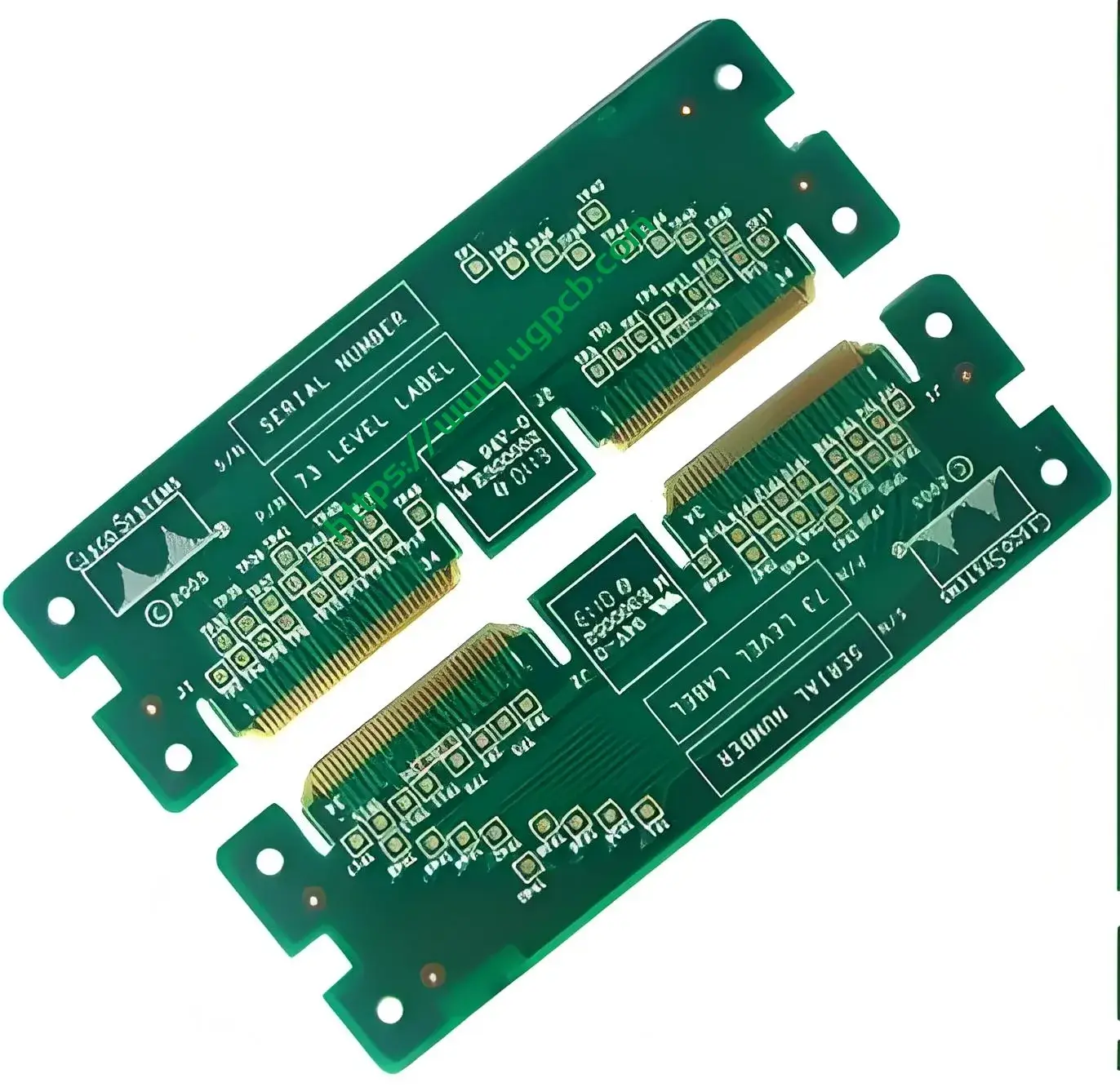

Dell Computer Connect PCB Board

재료

The Dell Computer Connect PCB Board is manufactured using high-quality FR-4 material. FR-4, also known as glass-epoxy laminate, is a flame-retardant grade of epoxy resin combined with woven glass fiber cloth. 이 재료는 우수한 전기 특성을 위해 선택됩니다, 기계적 강도, 내열, and flame retardancy, making it ideal for PCB applications.

성능

With a finished thickness of 1.6mm, the Dell Computer Connect PCB Board offers robust structural integrity while maintaining flexibility in design. The 6-layer construction allows for complex circuitry and high component density, supporting advanced functionality in Dell computers. The copper thickness of 1OZ ensures good conductivity and current carrying capacity, essential for reliable performance.

구조

The PCB board features a green/white solder mask, which not only provides a protective layer against environmental factors but also enhances visual inspection and component placement accuracy. The immersion gold surface treatment offers superior corrosion resistance and enhances the electrical connection between components and the PCB, 장기 신뢰성 보장.

Special Characteristics

One of the standout features of the Dell Computer Connect PCB Board is its golden finger process. Golden fingers are the plated edge connectors on the PCB that facilitate the connection between the board and other components or circuits. This special process ensures a secure, low-resistance connection, crucial for high-speed data transfer and signal integrity.

생산 과정

The production of the Dell Computer Connect PCB Board involves several precision steps:

- 디자인 및 레이아웃: The PCB design is meticulously planned and laid out using advanced CAD software.

- 재료 준비: High-quality FR-4 material is cut to size and prepared for processing.

- 회로 패터닝: The copper circuitry is etched onto the FR-4 base material using photolithography techniques.

- 레이어 라미네이션: Multiple layers are aligned and bonded together to form the final 6-layer structure.

- 시추 및 도금: Holes are drilled for component placement and interconnection, followed by plating to enhance conductivity.

- 표면 처리: The immersion gold process is applied to the PCB surface.

- Solder Mask and Legend Printing: A protective solder mask is applied, and component identifications are printed.

- Final Assembly and Testing: The PCB is assembled with components and thoroughly tested to ensure functionality and reliability.

응용 시나리오

The Dell Computer Connect PCB Board is specifically designed for use in Dell computers, where it serves as a critical component in connecting various internal systems and devices. Its advanced features make it suitable for a wide range of Dell computer models, from desktops to laptops, enabling seamless communication between hardware components and ensuring optimal performance. Whether used in high-performance gaming systems, business workstations, or everyday computing tasks, the Dell Computer Connect PCB Board plays a vital role in delivering reliable and efficient computing experiences.

UGPCB 로고

UGPCB 로고