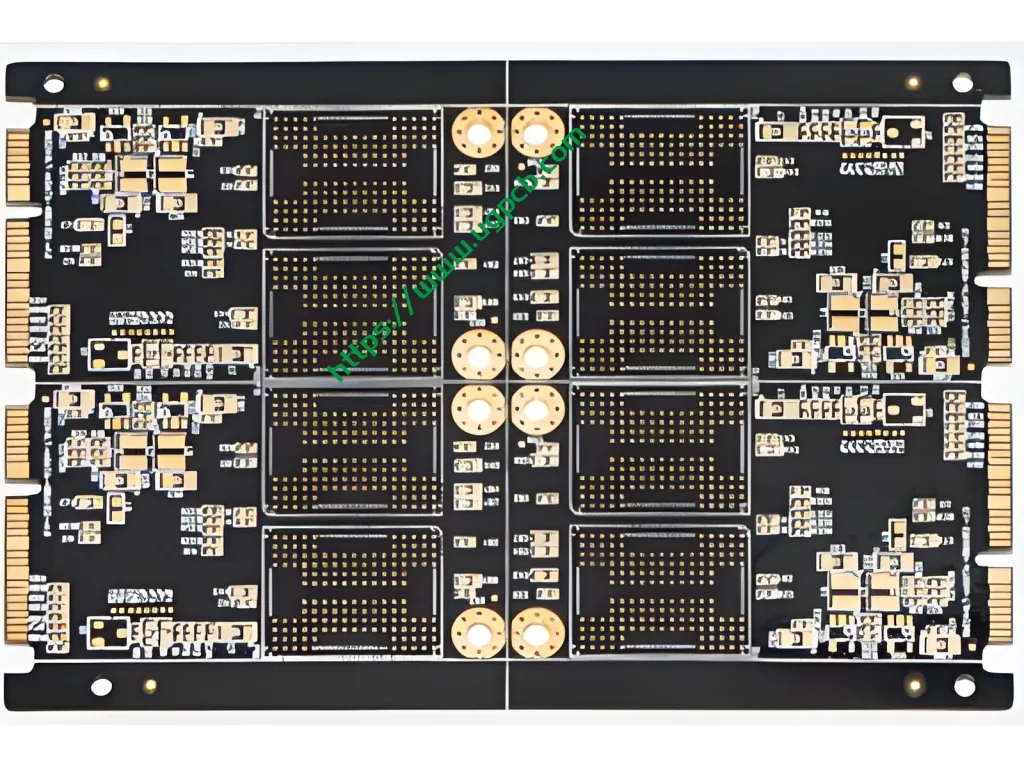

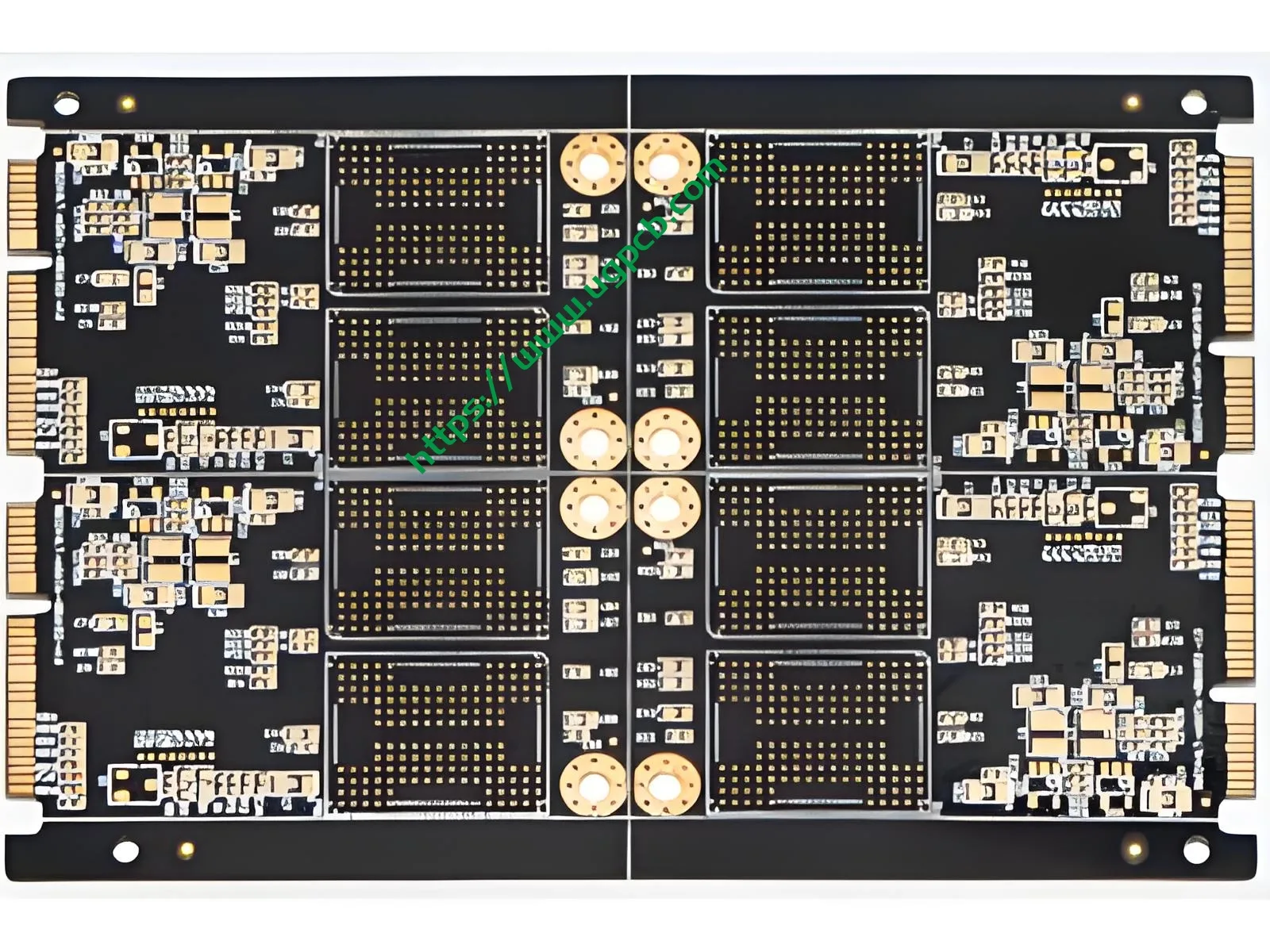

골드 핑거 블라인드 홀 PCB 소개

골드 핑거 블라인드 홀 PCB는 특수한 유형의 인쇄 회로 보드입니다. (PCB) 금도금 손가락과 블라인드 홀이 특징입니다. 이 설계는 전자 장치 내에서 향상된 연결 및 소형 통합을 가능하게합니다..

제품개요

Gold Finger Blind Hole PCB는 고품질 S1140 FR4 재료를 사용하여 구성됩니다., 내구성과 탁월한 전기 성능을 보장합니다. 그것은 4 개의 층으로 구성됩니다, 구리 두께가 1oz 및 완성 된 두께 1.2mm.. 표면 처리에는 침지 금이 포함됩니다, 이는 탁월한 전도도와 부식 저항을 제공합니다.

응용

이 유형의 PCB는 주로 컴퓨터 구성 요소에 사용됩니다., 고속 데이터 전송 및 안정적인 연결이 중요합니다. 금 손가락을 사용하면 쉽게 막고 플러그를 뽑을 수 있습니다, 블라인드 홀은 통과 구멍 구성 요소없이 내부 연결을 용이하게합니다..

분류

골드 핑거 블라인드 홀 PCB는 레이어 수에 따라 분류 할 수 있습니다., 구리 두께, 맹인 및 묻힌 Vias와 같은 특별 과정, 금 손가락과 블라인드 구멍의 존재뿐만 아니라.

재료

이 PCB의 기본 재료는 S1140 FR4입니다, 우수한 열 안정성과 기계적 강도를 제공하는 화염성 유리-에폭시 라미네이트.

성능

추적/공간 치수는 4mil/4mil입니다 (0.1MM/0.1MM) 및 최소 구멍 크기 0.2mm (8밀), 골드 핑거 블라인드 홀 PCB는 고밀도 상호 연결 응용 프로그램을 위해 설계되었습니다.. 몰입 금 마감은 접촉 저항이 낮고 장기 신뢰성을 보장합니다..

구조

PCB는 4 개의 층으로 구성됩니다, 맹인 및 매장 된 VIAS를 사용하여 통로 구성 요소없이 층 간의 복잡한 라우팅을 허용합니다.. 골드 손가락은 더 큰 시스템에 쉽게 통합 할 수있는 에지 커넥터 인터페이스를 제공합니다..

특징

Gold Finger Blind Hole PCB의 몇 가지 주요 기능은 다음과 같습니다.:

- 고밀도 상호 연결 기능

- 침수 금 마감으로 인한 접촉 저항이 낮습니다

- S1140 FR4 재료를 갖춘 내구성 있고 신뢰할 수있는 구조

- 금 손가락과 블라인드 구멍이있는 소형 디자인

생산 과정

골드 핑거 블라인드 홀 PCB의 생산 과정에는 여러 단계가 포함됩니다., 포함:

- 재료 준비: 적절한 S1140 FR4 재료를 선택하고 크기로 자릅니다..

- 레이어 스태킹: 정확한 정렬로 PCB의 층을 쌓습니다.

- 구리 에칭: 화학 에칭을 사용하여 각 층에서 원하는 회로 패턴을 만듭니다..

- 드릴링을 통해: 맹인과 매장 된 vias를 드릴링하여 레이어간에 내부 연결을 만듭니다..

- 도금: VIAS 및 기타 노출 된 구리 지역에 구리 도금 적용.

- 표면 처리: 개선 된 전도성 및 부식 저항을 위해 PCB 표면에 몰입 금을 적용.

- 집회: 쉽게 연결하기 위해 PCB 가장자리에 금 손가락을 조립.

사용 사례

골드 핑거 블라인드 홀 PCB는 공간이 제한되어 있고 고속 데이터 전송이 필요한 컴퓨터 구성 요소에 사용하기에 이상적입니다.. 예를 들어 마더 보드가 있습니다, 그래픽 카드, 기타 고성능 컴퓨팅 장치.

UGPCB 로고

UGPCB 로고