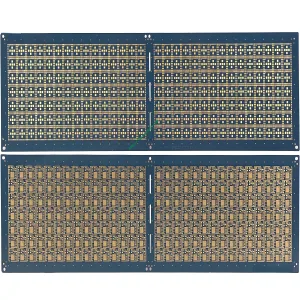

낮은 CTE 및 높은 계수

- 낮은 CTE 및 높은 계수, 패키지 운송 업체의 휘장을 효과적으로 줄일 수 있습니다.

- 우수한 열과 습도 저항

- 좋은 PCB 처리 가능성

-

할로겐이없는 재료

응용 프로그램 필드

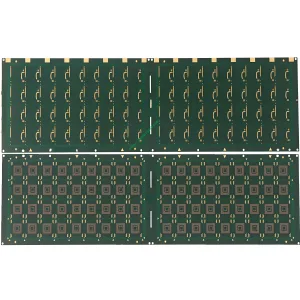

EMMC와 DRAM

- EMMC, 음주

AP 및 PA

- ap, 아빠

이중 CM

- 이중 CM

지문 및 RF 모듈

- 지문, RF 모듈

열 및 기계적 특성

- Tg (DMA): 280 섭씨온도

- Td (5% wt. 손실): >400 섭씨온도

- CTE (x/y 축) Tg 이전: 10 PPM/학위 섭씨

- CTE (Z축) A1/A2: 25/135 PPM/학위 섭씨

- 유전 상수 (1GHz): 4.4

- 소산 인자 (1GHz): 0.007

- 껍질 힘 (1/3 온스, VLP): 0.80 N/mm

- 땜납 담그기 (@288도 섭씨): >30 분

- 영률 (50 섭씨온도): 26 GPA

- 영률 (200 섭씨온도): 23 GPA

- 굴곡 계수 (50 섭씨온도): 32 GPA

- 굴곡 계수 (200 섭씨온도): 27 GPA

수분 흡수 및 가연성

- 수분 흡수 (에이): 0.14%

- 수분 흡수 (85 섭씨 85%RH, 168HR): 0.35%

- 가연성 (UL-94): 다섯-0

다른 속성

- 열전도율: 0.61 w/(M.K)

- 색상: 검은색

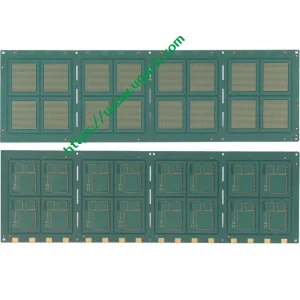

소개

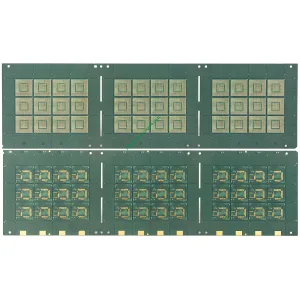

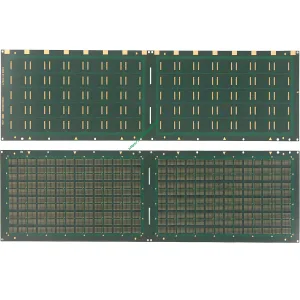

IC 캐리어 보드 포장 프레임은 IC 카드 모듈 포장에 사용되는 주요 특수 기본 자료를 나타냅니다.. 주로 칩을 보호하고 통합 회로 칩과 외부 세계 사이의 인터페이스 역할을합니다.. 그 형태는 리본입니다, 일반적으로 황금색.

사용 프로세스

특정 사용 프로세스는 다음과 같습니다: 첫 번째, IC 카드 칩은 완전 자동 배치 시스템에 의해 IC 카드 포장 프레임에 부착되어 있습니다., 그런 다음 IC 칩의 접점은 와이어 본딩 머신으로 IC 카드 포장 프레임의 노드에 연결됩니다.. 회로의 연결, 그리고 마지막으로 통합 회로 카드 모듈을 형성하기 위해 통합 회로 칩을 보호하기 위해 포장재를 사용합니다., 후속 응용 프로그램에 편리합니다.

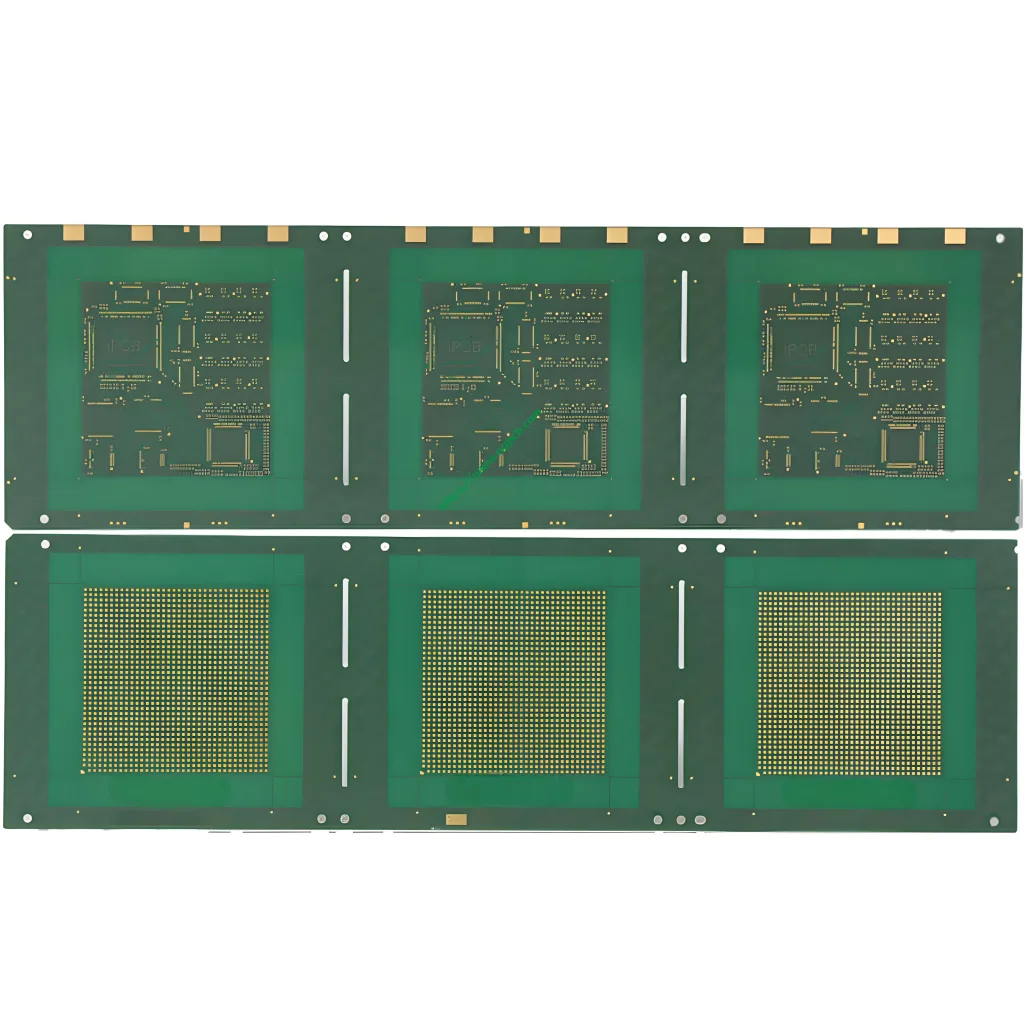

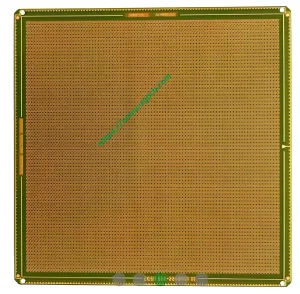

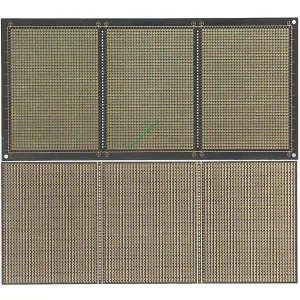

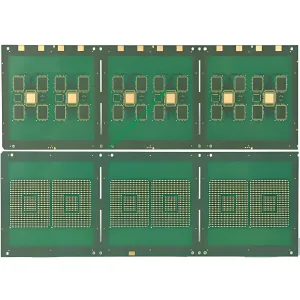

BGA 아키텍처 및 제조 공정

IC 캐리어 보드는 또한 BGA를 기반으로 한 제품입니다. (볼 그리드 어레이) 건축학. 제조 공정은 PCB 제품과 유사합니다., 그러나 정밀도는 크게 향상됩니다. 제조 공정은 PCB와 다릅니다. IC 기판은 IC 포장의 핵심 구성 요소가되었습니다., 리드 프레임의 일부를 점차적으로 교체합니다 (리드 프레임) 애플리케이션.

집적 회로

통합 회로는 칩에 일반 목적 회로를 통합합니다.. 그것은 전체입니다. 일단 내부적으로 손상되면, 칩도 손상되었습니다.

인쇄 회로 기판

PCB는 구성 요소 자체를 납땜 할 수 있습니다, 구성 요소가 파손 된 경우 교체하십시오.

IC 캐리어 보드

일반적으로, 칩의 캐리어 보드, 보드는 매우 작습니다, 일반적으로 a의 크기 1/4 손톱, 보드는 매우 얇습니다 (0.2~ 0.4mm), 사용 된 재료는 FR-5입니다, BT 수지, 회로는 2mil/약 2mil입니다. 대만에서 일반적으로 생산되었던 고정밀 보드입니다., 그러나 지금은 본토를 향해 경향이 있습니다. 업계의 수익률은입니다 75%. 이런 종류의 보드의 단가는 매우 높습니다., 일반적으로 PC에 따라 구입했습니다.

UGPCB 로고

UGPCB 로고