소개 4 계층 산업 제어 PCBA

개요

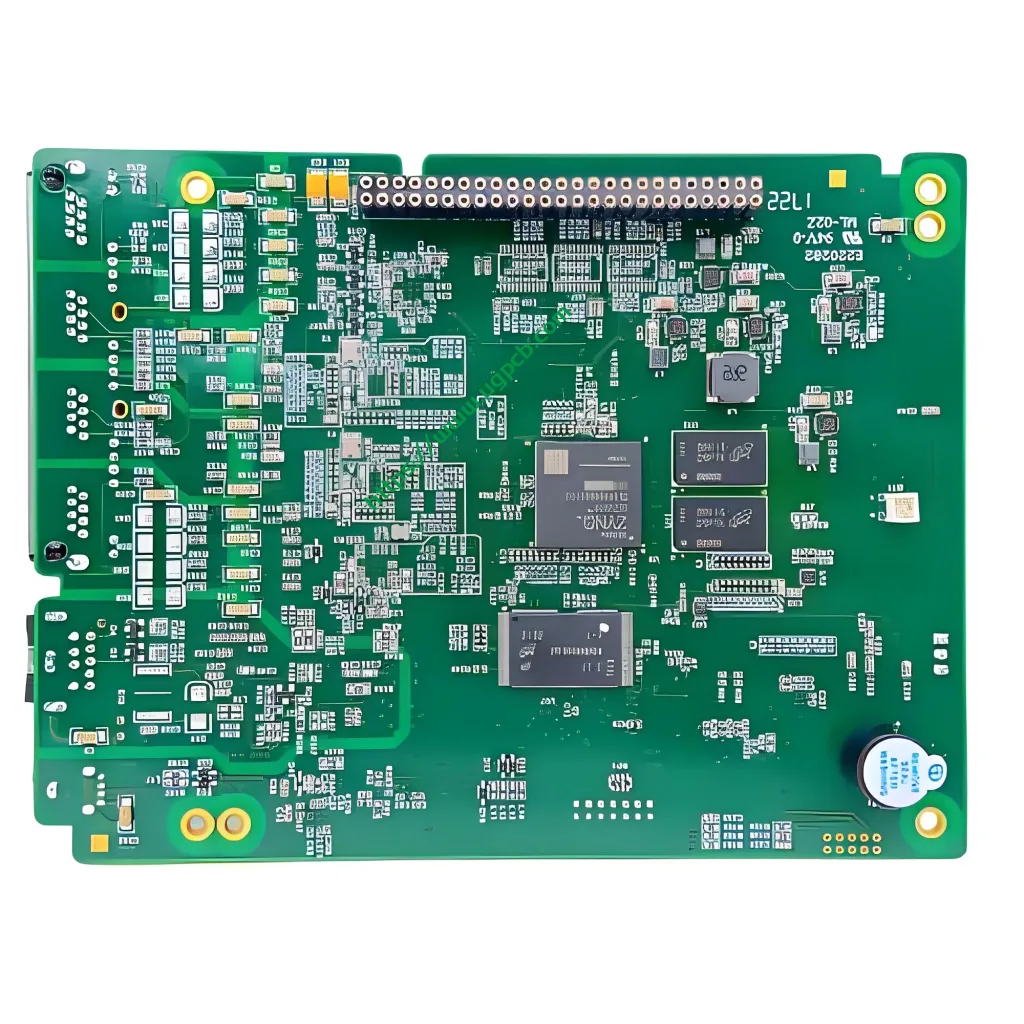

그만큼 4 계층 산업 제어 PCBA는 산업 제어 응용 프로그램을 위해 설계된 정교한 인쇄 회로 보드 어셈블리입니다.. 4 층의 전도성 재료가 특징입니다, 복잡한 회로 및 고밀도 구성 요소 배치를 허용합니다. 이 PCBA는 신뢰성과 성능으로 인해 다양한 산업 자동화 및 제어 시스템에 필수적입니다..

정의

에이 4 층 산업 제어 PCBA는 4 개의 구리 흔적을 통합 한 다층 인쇄 회로 보드 어셈블리, 유전체 층으로 분리됩니다. 이 설계는 산업 환경에 적합한보다 작고 효율적인 회로 설계를 가능하게합니다..

작동 원리

a의 작동 원리 4 층 산업 제어 PCBA. 이 층은 VIA를 통해 상호 연결됩니다 (도금 된 구멍) 전기 신호가 다른 층 사이를 이동하도록합니다. 표면 마운트 기술 (SMT) 그리고 통과 기술 (tht) 구성 요소는 PCB에 납땜됩니다, 기능 회로 생성.

응용

이 유형의 PCBA는 산업 제어 시스템에서 널리 사용됩니다., 포함:

- 자동화 장비

- 로봇 공학

- 기계 제어 장치

- 센서 인터페이스

- 발전 보드

분류

PCBA는 여러 기준에 따라 분류 될 수 있습니다:

- 층의 수에 의해: 단면, 양면, 다층 (포함 4 레이어)

- 구성 요소 유형별: 통로, 표면 마운트, 또는 둘의 조합

- 산업 표준에 따라: ROHS 준수, 무연, 등.

재료

a 4 계층 산업 제어 PCBA 포함:

- 전도성 층을위한 구리 호일

- 유전체 층을위한 유리 섬유 또는 복합 재료

- 무연 HASL (방열판 어셈블리 수준) 표면 마감

- 보호 및 단열재를위한 녹색 솔더 마스크

성능

이 PCBA의 성능은 특징입니다:

- 구리 층으로 인한 높은 열전도율

- 낮은 신호 손실 및 높은 신호 무결성

- 습도와 같은 환경 적 요인에 대한 저항, 온도 변화, 그리고 기계적 스트레스

- ROH 및 무연 모임 표준 준수

구조

a의 구조 4 계층 산업 제어 PCBA는 일반적으로 포함됩니다:

- 유전체 층으로 분리 된 4 개의 구리 트레이스

- vias (도금 된 구멍) 층간 연결을 위해

- 표면 마운트 및 홀 홀 구성 요소가 보드에 납땜되었습니다

- 보호 및 식별을 위해 상단 레이어를 덮는 녹색 솔더 마스크

특징

이 PCBA의 주요 기능에는 포함됩니다:

- 우주 제약 응용 분야에 적합한 고밀도 및 소형 설계

- 우수한 열 관리 기능

- 가혹한 산업 환경에서 내구성과 수명이 향상되었습니다

- 광범위한 전자 구성 요소와의 호환성

생산 과정

a의 생산 과정 4 계층 산업 제어 PCBA에는 여러 단계가 포함됩니다:

- 설계: 특수 소프트웨어를 사용하여 회로 레이아웃 및 구성 요소 배치를 생성합니다..

- 재료 준비: 구리 호일을 선택하고 준비합니다, 유전체 층, 및 기타 재료.

- 레이어 스태킹: 구리 및 유전체 재료의 층을 쌓는다.

- 드릴링을 통해: VIAS 용 쌓인 층을 통한 시추 구멍.

- 도금: 전기 연결을 보장하기 위해 구리로 VIA를 도금하십시오.

- 에칭: 원하는 회로 패턴을 형성하기 위해 여분의 구리를 제거합니다..

- 구성 요소 배치: PCB에 대한 표면 마운트 및 홀 구성 요소를 납땜합니다.

- 테스트: 기능 및 표준 준수를 보장하기 위해 엄격한 테스트 수행.

- 최종검사: PCBA가 모든 품질 및 성능 기준을 충족하는지 확인합니다.

사용 사례

에 대한 일반적인 사용 사례 4 계층 산업 제어 PCBA 포함:

- 높은 신뢰성과 성능이 중요한 산업 자동화 시스템

- 정확한 제어가 필요한 로봇 팔과 기계

- 까다로운 환경 조건을 가진 공장

- 중공업의 전력 분배 및 제어 패널

결론

그만큼 4 Layers Industrial Control PCBA. 다층 디자인, 고성능 재료, 그리고 업계 표준을 준수하는 것은 강력하고 효율적인 전자 솔루션을 원하는 엔지니어와 제조업체에게 이상적인 선택입니다..

UGPCB 로고

UGPCB 로고