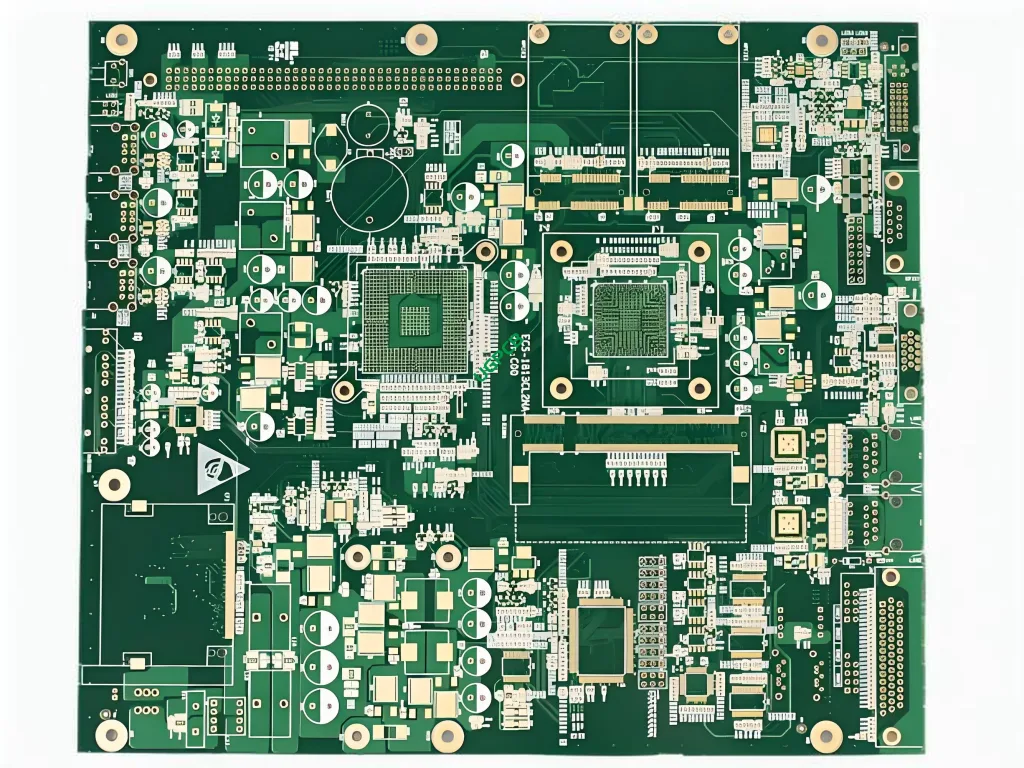

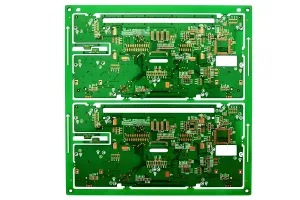

산업 컨트롤러 PCB 소개

산업 컨트롤러 PCB는 산업 제어 시스템을 위해 특별히 설계된 강력하고 안정적인 인쇄 회로 보드입니다.. 까다로운 환경에서 안정적이고 효율적인 운영을 보장합니다, 다양한 산업 응용 프로그램에 필수적입니다.

산업 컨트롤러 PCB 란 무엇입니까??

산업 컨트롤러 PCB, 또는 인쇄 회로 기판, 산업 제어 시스템에 사용되는 특수 전자 보드입니다.. 그것은 다양한 구성 요소를 수용하고 산업 기계 및 공정의 적절한 기능을 보장하기 위해 필요한 상호 연결을 제공합니다..

설계 요구 사항

산업 컨트롤러 PCB의 설계 요구 사항은 신뢰성과 성능을 보장하는 데 중요합니다.:

- 재료: EM-82, 내구성과 우수한 전기 특성으로 선택되었습니다.

- 레이어 수: 4 복잡한 회로 설계를 수용하기위한 레이어.

- 색상: 쉽게 식별하고 미적 호소를위한 흑백.

- 완성된 두께: 1.6MM은 지나치게 부피가 크지 않고 구조적 무결성을 제공합니다.

- 구리 두께: 1적절한 전도도를 보장하기위한 오즈.

- 표면 처리: 침지 금은 납땜 가능성 및 부식성을 향상시킵니다.

- 최소 추적 및 공간: 둘 다 6mil (0.15mm) 미세 회로 패턴을 지원합니다.

- 특성: 홀 구리는 25UM보다 큽니다..

어떻게 작동하나요??

산업 컨트롤러 PCB는 전도성 경로를 통해 다양한 전자 부품을 상호 연결할 수있는 플랫폼을 제공하여 작동합니다.. 이 경로, 또는 흔적, 구리로 만들어졌으며 보드에 새겨 져 있습니다.. 침지 금 표면 처리는 이러한 흔적이 전도성을 유지하고 환경 요인에 내성을 유지하도록합니다..

응용

산업 컨트롤러 PCB의 주요 응용 프로그램은 산업 제어 시스템에 있으며 기계 및 프로세스의 운영을 관리하고 규제합니다.. 여기에는 포함됩니다:

- 자동화 된 제조 시스템

- 산업용 로봇 공학

- 프로세스 제어 시스템

- 공작 기계 도구 컨트롤러

분류

기능 및 응용 프로그램을 기반으로합니다, 산업용 컨트롤러 PCB는 산업용으로 설계된 고 신뢰성 PCB로 분류 될 수 있습니다.. 이 분류는 가혹한 산업 환경을 견딜 수있는 능력을 강조합니다..

재료 구성

산업 컨트롤러 PCB에 사용되는 핵심 자료는 EM-82입니다., 우수한 기계식으로 알려진 고성능 라미네이트 재료, 열의, 및 전기 특성. 이 자료는 PCB가 산업 응용 분야의 요구를 견딜 수 있도록합니다..

성능 특성

산업 컨트롤러 PCB의 성능 특성에는 포함됩니다:

- 높은 신뢰성

- 우수한 신호 무결성

- 우수한 열 관리

- 강력한 기계적 강도

- 장기 안정성

구조적 세부 사항

산업 컨트롤러 PCB의 구조적 세부 사항은 다음과 같습니다.:

- 레이어 수: 4 레이어

- 완성된 두께: 1.6mm

- 구리 두께: 1온스

- 최소 트레이스 너비: 6밀 (0.15mm)

- 흔적 사이의 최소 공간: 6밀 (0.15mm)

- 표면 처리: 이머젼 골드

- 구리 구리 두께: 25UM보다 큽니다

특징 및 이점

산업 컨트롤러 PCB의 주요 기능과 이점은 다음과 같습니다.:

- 고밀도 상호 연결성

- 우수한 신호 무결성

- 강력한 기계적 구성

- 신뢰할 수있는 장기 성능

- 미적 색상 옵션 (흑백)

생산 과정

산업 컨트롤러 PCB의 생산 프로세스에는 여러 단계가 포함됩니다., 포함:

- 재료 선택: 고품질 EM-82 재료 선택.

- 레이어 스태킹: 배열 4 정밀한 레이어.

- 에칭: 과도한 구리를 제거하여 원하는 트레이스 패턴을 형성합니다.

- 도금: 침지금 표면 처리 적용.

- 집회: 레이어 상호 연결을 위해 PTH 및 VIAS를 통합합니다.

- 테스트: PCB가 모든 성능 사양을 충족하는지 확인합니다.

사용 사례

산업 컨트롤러 PCB는 다양한 시나리오에서 사용됩니다, ~와 같은:

- 자동화 된 제조 라인

- 산업 로봇 제어 시스템

- 공정 제어 장비

- 공작 기계 자동화

요약하면, 산업 컨트롤러 PCB는 산업 제어 시스템의 까다로운 요구 사항을 충족하도록 설계된 정교하고 신뢰할 수있는 구성 요소입니다.. 고밀도 디자인, 우수한 성능 특성, 강력한 건축은 모든 고급 산업 설정의 필수 부분입니다..

UGPCB 로고

UGPCB 로고