응용:

자동차, 백플레인, RF/전자 레인지, 고급 컴퓨팅

신호 무결성, 의료, 군대, 모바일 장치/무선 핸드셋

철도, 서버, 스위치/라우터, 열 관리, 무선 인프라

Isola PCB는 무엇을 의미합니까??

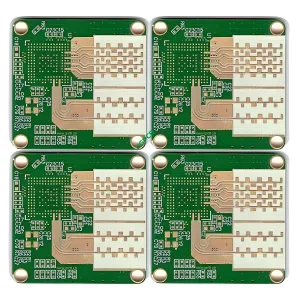

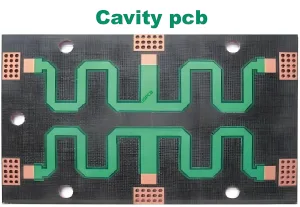

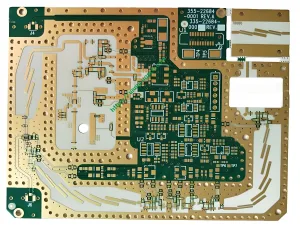

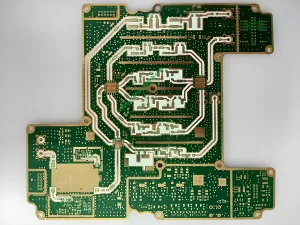

이 유형의 인쇄 회로 보드는 복잡하고 고성능 라미네이트를 사용하여 제조됩니다.. 까다로운 성능 요구 사항을 충족하도록 설계된 수지 구성 요소가 포함되어 있습니다..

이 유형의 PCB는 항공 우주 장비 및 고급 소비자 전자 제품과 같은 대부분의 전자 장치에서 사용됩니다..

Isola PCB에 사용되는 재료의 유형

Isola PCB를 제조하는 데 사용되는 재료가 있습니다. 그들 중 일부에는 포함됩니다:

프리프레그

이 용어는 PCB 산업과 관련이 있습니다. 이것을 불립니다 “준비”. 이것은 전기 절연을 제공하는 유전체 재료입니다, 다른 중요한 기능뿐만 아니라. 독특하게 제조 된 수지가있는 유리 섬유 직물로 만들어졌습니다..

이 수지는 다른 열을 결합합니다, 전기 같은, 및 Prepreg와의 물리적 특성. 이것은 Isola PCB의 올바른 작동에 중요합니다..

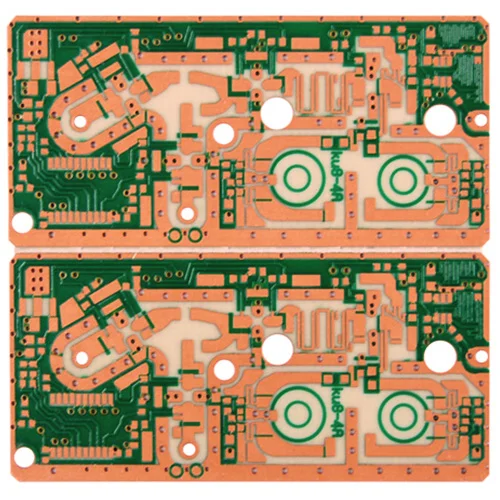

구리 클래드 라미네이트

여기에는 양쪽 끝에 얇은 구리 호일 층이있는 Prepreg 라미네이트가 포함됩니다.. 이 라미네이션은 하나 이상의 구리 층을 압축하여 달성됩니다., 압력, 진공 상태.

다층 Isola PCB 구축

Prepreg 및 CCL은 종종 반복되는 여러 프로세스를 포함하는 복잡한 작업을 통해 다층 Isola PCB를 제조하는 데 사용됩니다..

라미네이트의 구리 표면이 에칭된다. 이것은 전자 회로를 생성하기위한 것입니다. 다음, 라미네이트는 각각 에칭 된 라미네이트 사이에 하나 이상의 Prepreg 층을 삽입하여 다층 구조를 형성함으로써 조립됩니다..

그런 다음 전기 도금 및 드릴링은 PCB 층 간의 전기 상호 연결을 형성합니다.. 결과 Isola PCB는 반도체 및 기타 구성 요소가 장착되는 상호 연결 가제트입니다..

Isola PCB 응용 프로그램

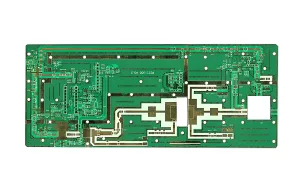

Isola PCB의 라미네이트 및 Prepreg는 다양한 장치 및 고급 전자 제품에 사용됩니다., 포함:

항공 우주 응용

군사 전자 제품 응용 프로그램

산업 장비 응용

고급 소비자 전자 제품

네트워킹 및 기타 통신 장비

자동차 응용 프로그램

의료 기기 응용 프로그램

Isola PCB의 수지 시스템에 사용되는 재료?

Isola PCB는 플로우 프리프 레그를 사용합니다, 폴리이 미드를 기반으로하며 고온이 필요한 PCB 응용 분야에 적합합니다..

그들은 폴리이 미드 불꽃 지연 수지 시스템을 사용합니다, 우수한 성능 및 열 특성이 필요한 응용 프로그램에 이상적입니다.. Isola의 Prepreg는 메틸렌 다이애닐린을 사용하지 않고 완전히 경화 될 수있는 폴리이 미드 및 열가소성 수지의 혼합을 사용합니다. (MDA).

이것은 높은 Tg를 갖는 중합체를 초래한다, Brittleness와 낮은 초기 결합 강도 문제없이. 결과적으로, Isola PCB의 수지 시스템은 전통적인 열경화 폴리이 미드의 수지 구조보다 훨씬 우수합니다..

Isola Prepregs의 특성

다음은 Isola PCB 재료의 주요 특성입니다.:

고온에서 결합 강도를 유지합니다

할로겐이없는 옵션으로 제공됩니다

더 높은 열 성능

가공으로 인한 박리를 줄입니다

Brittleness 감소로 인해 처리 가능성이 향상됩니다

수지 시스템의 긴 서비스 수명

UGPCB 로고

UGPCB 로고