Introduction to Medical Device PCB

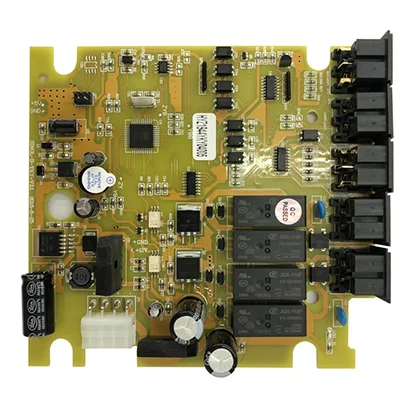

인쇄 회로 기판 (PCB) 기술 세계의 지속적인 성장과 다양한 분야에서의 활용으로 인해 비즈니스는 거부할 수 없는 유익한 영향력을 확대해 왔습니다.. 최근에는, 전자 세계에 미치는 영향은 모든 예측을 초과했습니다., IoT 기기를 비롯한, 스마트폰, 컴퓨터, 인공지능, 그리고 더. 지금, PCB는 의료 기기를 변화시키고 의료 기술 사업에서 환자와 의사 사이의 격차를 해소하고 있습니다., enabling the development of convenient medical devices that help solve key challenges in healthcare.

The Growing Importance of PCBs in Medical Electronics

The medical electronics industry is growing rapidly and shows no signs of slowing down, highlighting the significant influence of PCBs in the medical field. The global medical electronics market is projected to reach $4.4 10억 단위로 2022. With technological advancements, PCBs are becoming increasingly crucial in medical devices, as most modern medical gadgets require them to function properly and efficiently. PCBs are essential for operating medical equipment such as defibrillators, 전기 근육 자극 장치, MRI machines, 의료 영상 시스템, CT 스캔, 그리고 초음파 장비.

의료용 PCB 기술 및 유형

Ensuring Reliability and Cleanliness

Extra care is taken in producing medical PCBs to ensure reliability, given that human life depends on the equipment they power. Medical PCBs must meet strict hygiene and cleanliness requirements, especially those used in implants. 고밀도 상호 연결 (HDI) PCBs are commonly used in medical devices to achieve the necessary compactness and reliability.

의료용 PCB 조립에 사용되는 기술

HDI / 패드를 통해 기술

The design of inserting vias inside copper pads, known as via-in-pad, saves space on the PCB and provides up to 50% 구성 요소 배치를 위한 더 많은 공간. This technique is favored by PCB engineers for creating smaller, more acceptable pitch devices. Blind and buried vias also help reduce space, but via-in-pads remain the best choice for high-speed and high-dissipation PCBs.

표면 실장 기술

표면 실장 기술 (SMT) is widely used in commercial device manufacturing due to its advantages in the PCB manufacturing process. SMT components are smaller, allowing more electronic devices to be packaged in a smaller space. SMT also enables automated soldering and PCB assembly, improving reliability and cost-effectiveness.

PCB 미세한 선과 공간

Next-generation portable electronic devices rely on HDI PCB technology with tiny lines and spaces (2 백만 이하). This technology offers reduced board size, 강화된 배선, and lower manufacturing costs compared to conventional techniques.

Application of UGPCB in the Healthcare Industry

UGPCB plays a vital role in the medical industry, not only in appliances but also in monitoring, diagnostic, and therapeutic equipment. With technological advancements, UGPCB’s applications in healthcare are rapidly expanding, 새로운 가능성을 열어가다.

Common Applications

- 스캐닝 장비: CT 스캐너, 엑스레이 스크린, and ultrasound scans all rely on electronic components.

- 모니터: 심박수 모니터와 같은 의료 모니터링 장치, 혈당 모니터, 혈압계에는 전자 부품이 포함되어 있습니다..

- 의료 기기: Medical research requires various instruments with PCBs, such as electron microscopes, 제어 시스템, and compressors.

Higher Standards and Quality Requirements

건강상의 문제로, UGPCBs must meet higher standards in the medical industry. These devices must be reliable, of good quality, and often smaller in size to meet medical requirements.

Our Services

We provide Medical Equipment Turnkey PCB Assembly, medical PCB assembly, and Turnkey PCB Assembly services. UGPCB is your one-stop Turnkey PCB Assembly factory.

UGPCB 로고

UGPCB 로고