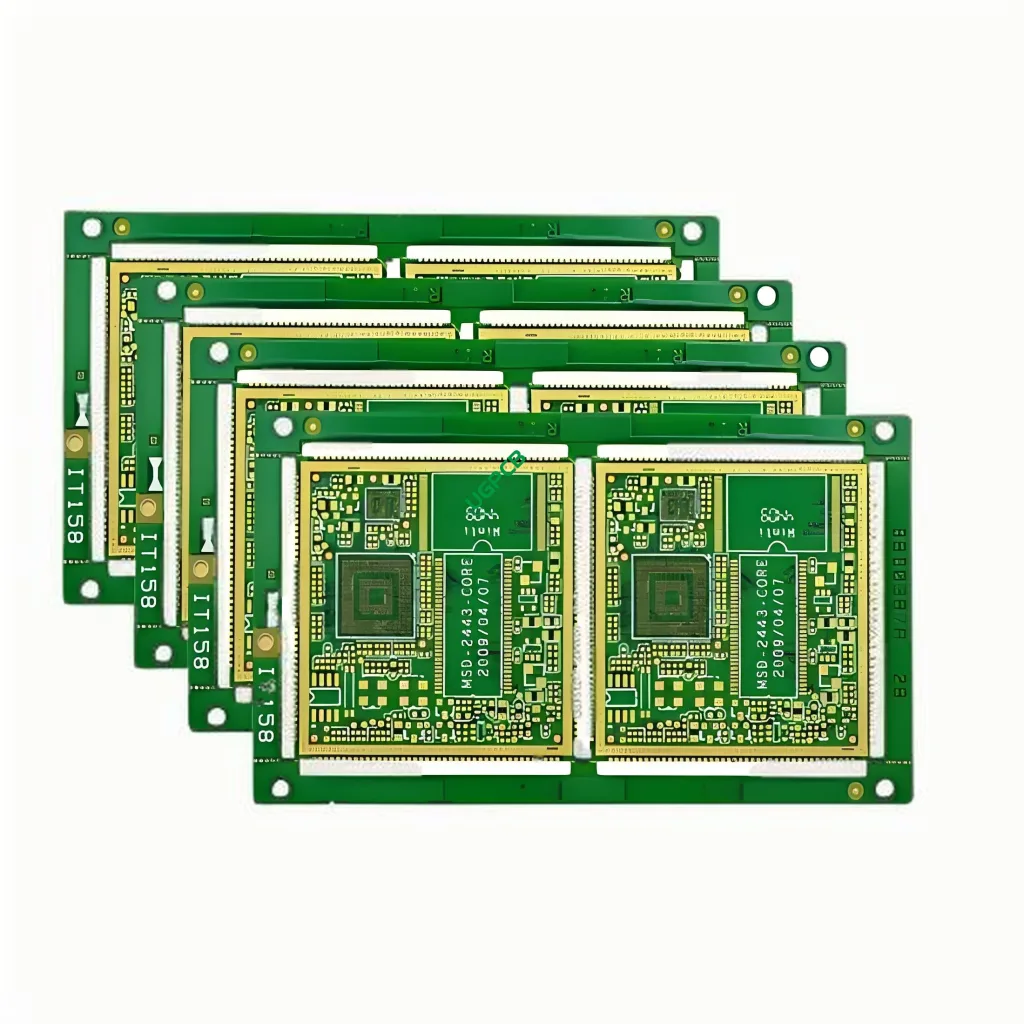

다층 차량 WiFi 모듈 PCB의 개요

다층 차량 Wi -Fi 모듈 PCB는 자동차 WiFi 및 Bluetooth 애플리케이션의 엄격한 요구 사항을 충족하도록 설계된 특수 제품입니다.. 이 유형의 PCB는 높은 정밀도를 제공합니다., 신뢰할 수 있음, 성능, 다양한 차량 내 통신 시스템에 이상적인 선택.

정의

다층 차량 Wi -Fi 모듈 PCB는 자동차 애플리케이션에서 WiFi 또는 Bluetooth 모듈의 기능을 지원하도록 특별히 설계된 인쇄 회로 보드입니다.. 여러 층의 전도성 및 절연 재료로 구성됩니다., 모듈 작동에 필수적인 복잡한 전기 경로 및 연결 제공.

설계 요구 사항

다층 차량 Wi -Fi 모듈 PCB를 설계 할 때, 몇 가지 주요 요구 사항을 충족해야 합니다.:

- 재료 품질: 고품질 FR4 소재는 내구성과 신호 무결성에 필수적입니다..

- 레이어 구성: 6레이어 디자인이 표준입니다., 복잡한 회로 및 신호 라우팅 가능.

- 구리 두께: 1OZ의 구리 두께로 적절한 전도성 보장.

- 표면 처리: 침수 금 표면 처리로 연결성과 내식성이 향상되었습니다..

- 추적/공간 차원: 3mil의 최소 추적 및 공간 치수 (0.75mm) 정밀한 회로 패턴이 필요합니다..

- 특별한 기능: Half-Hole PCB 설계는 종종 특정 구성 요소 배치 및 납땜 요구 사항을 위해 통합됩니다..

작동 원리

The multilayer vehicle WiFi module PCB operates based on the principles of electrical conductivity and insulation. 전도성 층은 전기 신호의 경로를 형성합니다., 절연층은 이러한 신호 간의 원치 않는 상호 작용을 방지합니다.. 침지형 금 표면 처리로 우수한 연결성을 제공하고 환경 요인으로부터 보호합니다..

응용

This type of PCB is primarily used in automotive WiFi and Bluetooth modules, which are crucial components in various in-vehicle communication and entertainment systems. 여기에는 다음이 포함됩니다:

- In-vehicle WiFi hotspots

- Bluetooth connectivity for hands-free calling and audio streaming

- Telematics and remote diagnostics systems

- Infotainment systems

분류

Multilayer vehicle WiFi module PCBs can be classified based on their specific features and intended use, ~와 같은:

- Communication Boards: For handling wireless communication signals in vehicles.

- 제어 보드: 전자 시스템의 다양한 기능을 관리하고 제어합니다..

- 발전 보드: 복잡한 전자 시스템에서 전원 공급 장치를 관리합니다.

재료

The primary materials used in the construction of a multilayer vehicle WiFi module PCB include:

- 기본 재료: FR4, 우수한 유전 특성과 기계적 강도로 유명한 난연성 유리 섬유 소재.

- 전도성 재료: 구리, 전도성 트레이스에 사용됨.

- 표면 처리: 이머젼 골드, 연결성을 강화하고 내식성을 제공하는 제품.

성능

다층 차량 Wi -Fi 모듈 PCB의 성능은 특징입니다.:

- 높은 신호 무결성: 정확한 추적/공간 치수 및 고품질 재료로 인해.

- 안정적인 연결: 침지 금 표면 처리로 보장.

- 내구성: 견고한 FR4 기본 소재로 강화됨.

- 전기 효율성: 최적화된 레이어 구성으로 신호 손실 및 간섭 최소화.

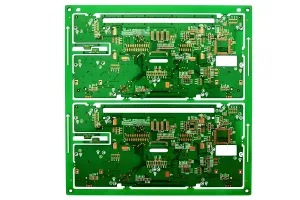

구조

다층 차량 Wi -Fi 모듈 PCB의 구조는:

- 6개 층의 전도성 재료: 절연층과 교대로 사용.

- 침지 금 표면 처리: 향상된 연결성 및 보호를 위해.

- 하프 홀 디자인: 특정 부품 배치 및 납땜 요구 사항.

특징

다층 차량 Wi -Fi 모듈 PCB의 주요 기능:

- 고급 표면 처리: 뛰어난 연결 품질을 위한 금침침.

- 높은 정밀도: 3mil의 최소 추적 및 공간 치수 (0.75mm).

- 사용자 정의 가능한 색상 옵션: 녹색 또는 흰색으로 제공됩니다..

- 표준두께: 완성두께 1.0mm로.

생산 과정

다층 차량 WiFi 모듈 PCB의 생산 공정에는 여러 단계가 포함됩니다.:

- 재료 준비: FR4 시트 및 동박 선택 및 준비.

- 레이어 스태킹: 구리와 절연 재료의 교대 층.

- 에칭: 원하는 회로 패턴을 형성하기 위해 여분의 구리를 제거합니다..

- 도금: 침지금 표면 처리 적용.

- 라미네이션: 열과 압력 하에서 층 결합.

- 교련: 관통 구멍 구성요소 및 비아용 구멍 생성.

- 솔더 마스크 적용: 솔더 브리지 및 환경 요인으로부터 회로 보호.

- 실크스크린 인쇄: 구성 요소 배치 및 식별을 위한 텍스트 및 기호 추가.

- 품질 관리: PCB가 모든 설계 사양 및 표준을 충족하는지 확인.

시나리오 사용

다층 차량 Wi -Fi 모듈 PCB는 시나리오에 이상적입니다.:

- 높은 신호 무결성이 중요합니다.

- 안정적이고 내구성 있는 연결이 필요합니다..

- 공간 제약으로 인해 컴팩트하고 효율적인 디자인이 필요합니다..

- 성능 향상을 위해서는 고급 표면 처리가 필요합니다..

UGPCB 로고

UGPCB 로고