OEM Turnkey high frequency Medical pcb circuit board manufacturer medical pcb assembly

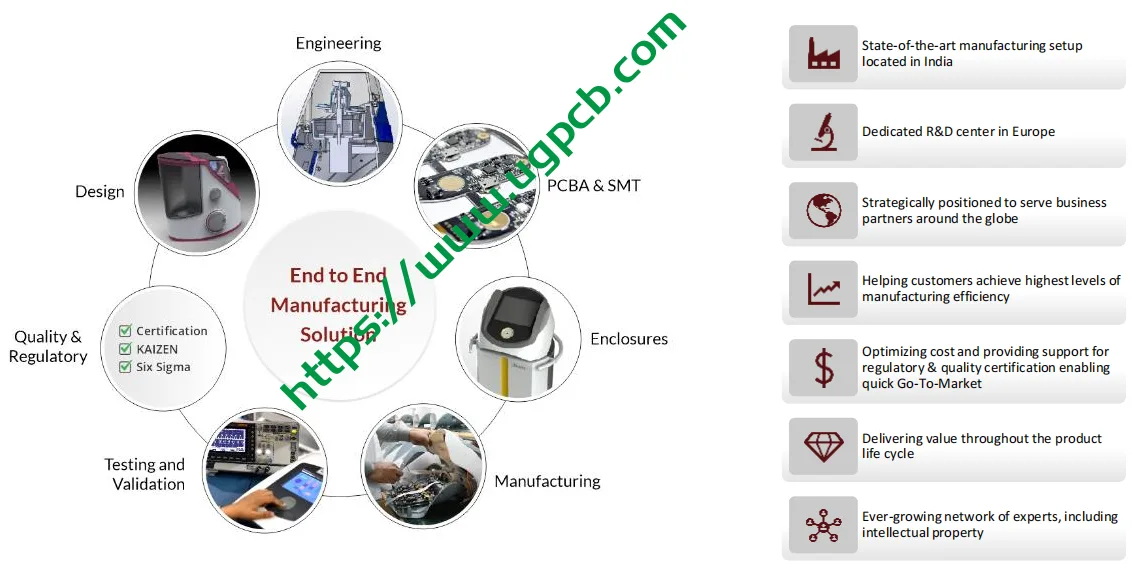

Main service items

OEM Turnkey high frequency Medical pcb circuit board manufacturer medical pcb assembly

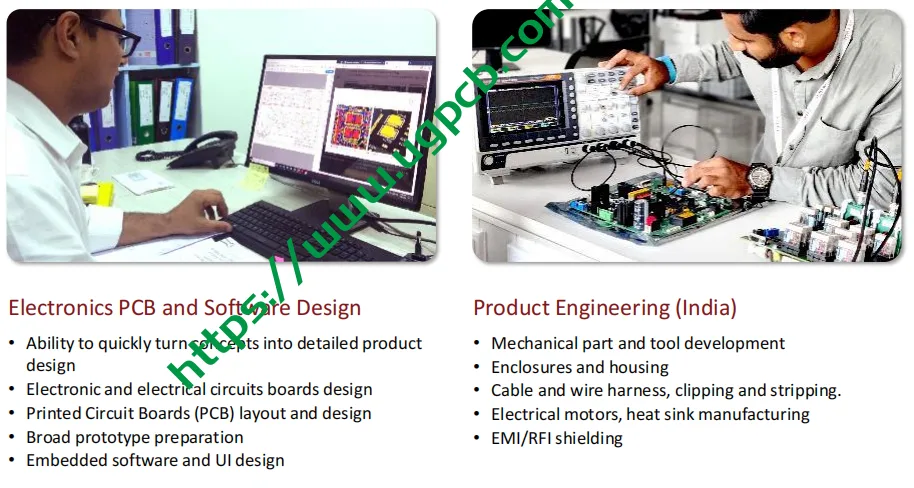

Internal Capabilities

Transition to Manufacturing

Healthcare and Medical PCB Applications We Serve

UGPCB manufactures and assembles medical PCBs for various medical devices, ~와 같은:

의료영상장비

Medical monitoring systems

Robotic surgery

Radiation therapy or radiotherapy

Medical PCB Testing Standards We Follow

We conduct continuous testing at every step of the manufacturing process to ensure the reliability of medical technology circuit boards.

자동 광학 검사 (AOI): AOI uses a single 2D camera or two 3D cameras to capture images of the PCB. The captured images are compared with the schematic diagram. If the circuit board does not match the schematic, it is sent for manual inspection.

Solderability Test: Ensures reliable solder joints.

Ion Contamination Test: Conducted to detect ionic residues produced during manufacturing and soldering steps.

Peel Test: Determines the strength measurement required to peel off laminates from the circuit board.

Microsection Analysis: Conducted to determine the quality of the circuit board and discover internal faults.

Flying Probe Test: Test probes move from one test point to another test point and check for open circuits, 단락, and other issues.

Time Domain Reflectometer (tdr): TDR impedance measurement is crucial for ensuring signal integrity. It also checks for electrical breaks in connectors or any other electrical paths.

How Do We Meet Your High Reliability Requirements Through Full Traceability?

According to IPC-6012 Class 2 and Class 3, we build precision standard boards, advanced boards, and mini boards. Our advanced circuit boards comply with the UL 94 다섯-0 flammability standard. We provide the following documents and certificates:

Compliance certificate

Material specification

First piece inspection report

Reflow profile copy (included in the first article)

Photo requirements

IPC J-STD-001이자형

Records of all calibrated tools used in the manufacturing process

AOI report or visual inspection report

Flying probe or in-line test report

Ion cleanliness test report

We follow the following standards, helping us build high-quality, reliable medical PCBs for the healthcare and medical technology industry.

IPC 6011: Defines performance specifications for Class 1, 수업 2, and Class 3 PCB

IEC 60601-1: General requirements for basic safety and essential performance of medical electrical equipment

IEC 60601-1-2: Defines electromagnetic requirements (EMI and EMS) for medical PCBs

ISO 13485: Provides quality management system requirements for medical devices

We provide DFM/DFA checks on each board

We focus on DFM and DFA analysis to prevent issues and provide an internal quality review system to ensure zero defect boards. We also offer engineering support to verify that your design is set up to perform as intended and meets IPC Class 3 standards if you choose this standard.

Extensive Electrical Testing of Medical PCBs

We do not compromise on quality and follow strict manufacturing standards required for medical boards—meaning continuous testing at every step of the manufacturing process, such as cross-section, AOI, BGA X-ray, flying probe, and other electrical tests.

One-Stop Manufacturing and Assembly

Poor communication between different manufacturing workshops and assembly workshops can lead to delivery delays and circuit board errors. PCB manufacturers who do not handle assembly do not run DFA checks to ensure your circuit boards can be correctly assembled. One supplier is responsible.

How to Get a Quote for Medical PCBs

Let us run DFM/DFA analysis for you and return the report to you. You can securely upload your files through our website.

We need the following information to give you a quote:

Gerber, ODB ++, or IPC-2581

BOM if you need assembly

Quantity

Turnaround time

UGPCB 로고

UGPCB 로고