RIDID-FLEX PCB: 주요 특징 및 장점

얇은 프로파일 및 가변 모양

Rigid-Flex PCB의 주요 기능 중 하나는 얇은 프로파일과 가변 모양입니다., 초박형 및 초등 포장에 이상적인 솔루션. Rigid-Flex 보드는 설계 및 제조에 더 비쌀 수 있지만, 그들은 많은 장점을 제공하고 전통적인 강성 보드 기술과 관련된 많은 문제를 해결합니다..

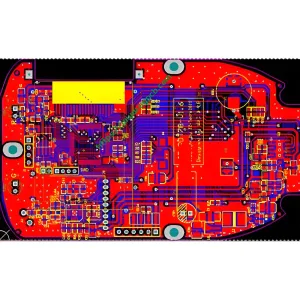

작은 크기와 유연한 모양

Rigid-Flex PCB는 특정 윤곽에 따라 모양을 변경할 수 있기 때문에 작은 공간에서 더 많은 구성 요소를 쉽게 맞출 수 있습니다.. 이 기술은 최종 제품의 크기와 무게와 전체 시스템 비용을 줄입니다.. 동시에, Rigid-Flex PCB의 소형 형태 계수는 HDI 기술의 얇은 라인 및 고밀도 회로를위한 최상의 선택입니다..

다른 응용 프로그램에 대한 사용자 정의

패키지 지오메트리 Rigid-Flex PCB의 자유는 많은 산업 분야의 응용 분야에 맞춤화 할 수 있습니다., 항공 우주를 포함하여, 군대, 의료기기, 그리고 가전제품. 주택 디자인 및 3D 디자인에 맞게 크기와 모양을 맞춤화 할 수 있습니다., 디자이너는 특정 응용 프로그램에서 다른 요구 사항을 충족시킬 수있는 더 많은 가능성을 제공합니다..

기계적 안정성 및 성능

더 나은 기계적 안정성

강성 보드의 안정성과 유연한 보드의 유연성은 전체 패키지의 안정적인 구조를 형성합니다., 작은 공간에 설치하는 데 필요한 전기 연결의 신뢰성과 유연성을 유지하는 동안.

가혹한 환경에서 더 나은 성능

Rigid-Flex PCB는 충격 및 진동 저항이 높습니다, 따라서 스트레스가 많은 환경에서 잘 작동 할 수 있습니다. Rigid-Flex PCB에는 케이블과 커넥터가 적습니다, 또한 향후 용도로 안전 위험과 유지 보수를 줄입니다..

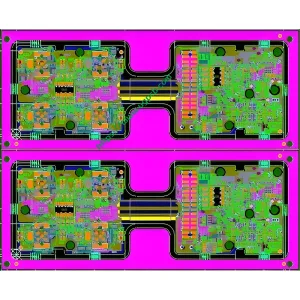

제조 및 테스트

제조 및 테스트가 쉽습니다

Ridid-Flex PCB에는 더 적은 수의 상호 연결 및 관련 구성 요소/부품이 필요합니다.. 이는 조립 작업을 단순화하는 데 도움이됩니다, Rigid-Flex PCB를보다 쉽게 조립하고 테스트 할 수 있도록합니다. Ridid-Flex PCB는 PCB 프로토 타이핑에 적합합니다.

UGPCB 로고

UGPCB 로고