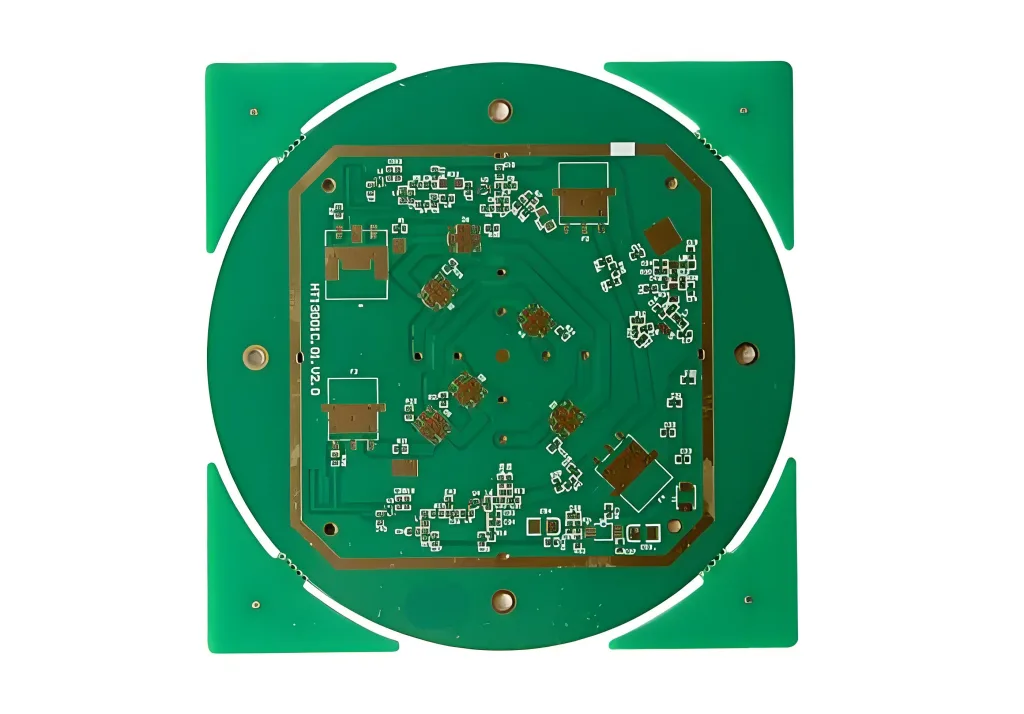

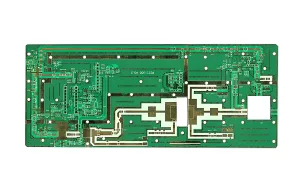

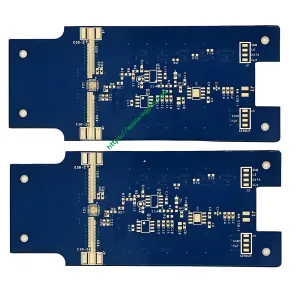

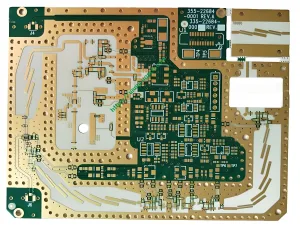

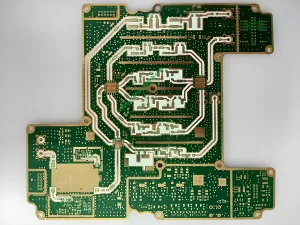

로저스 RT / 두로이드 RO6002 PCB 재료

로저스 RT / 두로이드 RO6002 PCB 마이크로파 재료는 일종의 저 유전 상수 라미네이트입니다., 복잡한 전자 레인지 구조 설계에서 기계적 신뢰성 및 전기 안정성의 엄격한 요구 사항을 충족 할 수 있습니다..

유전 상수의 온도 의존성을 측정 하였다 – 55OC + 150OC. 결과는 재료의 유전 상수가 온도 변화에 대한 저항성이 우수하다는 것을 보여줍니다., 필터의 요구 사항을 충족 할 수 있습니다, 설계에서 안정적인 전기 성능을위한 오실레이터 및 지연 라인 디자이너.

Rogers RO6002 PCB 주요 장점

1. 낮은 손실은 고주파에서 탁월한 성능을 보장합니다

2. 엄격하게 제어 된 유행 및 두께 내성

3. 우수한 전기 및 기계적 특성

4. 온도에 따른 유전 상수 변화율이 매우 낮습니다.

5. 구리 포일과 동등한 표면 팽창 계수

6. 낮은 z 축 확장

7. 배기 속도가 낮습니다, 항공 응용 프로그램에 이상적인 자료

PCB 응용: 위상 배열 안테나,지상 기반 및 공중 레이더 시스템, 글로벌 포지셔닝 시스템, 전원 백플레인,높은 신뢰성 복잡한 다층 회로, 상업용 항공 안티 충돌 시스템,빔 포밍 네트워크

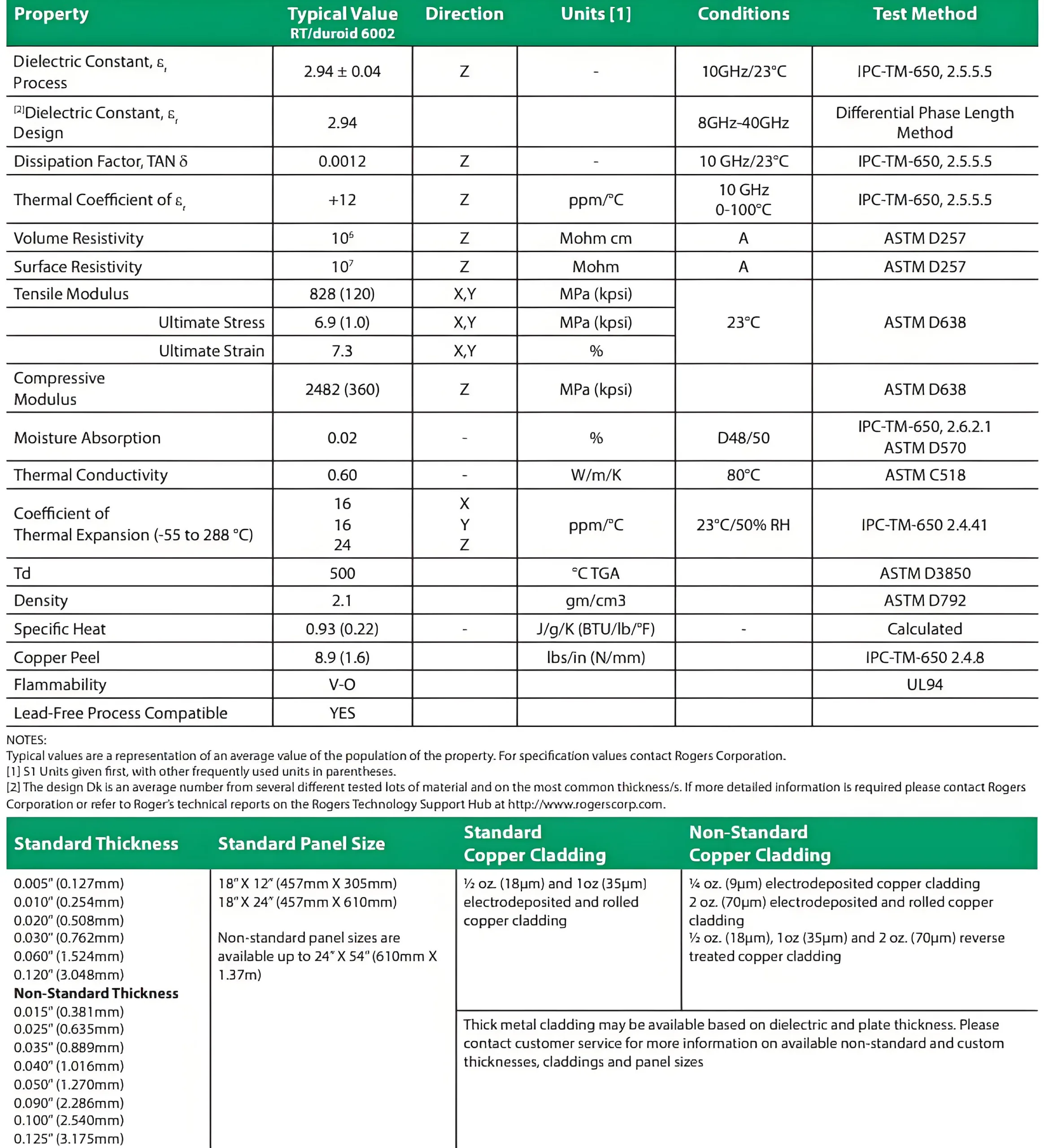

Rogers RO6002 PCB 기판 매개 변수 테이블

Rogers RO6002 자료에 대한 더 많은 기술 정보, 방문하십시오: Rogers RO6002 기술 사양

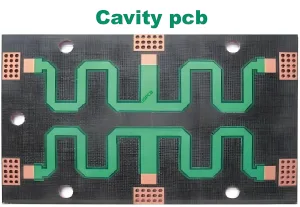

RT / Duroid6000 시리즈, RO3000 시리즈 및 RO3200 시리즈 ™ 시리즈 고주파 PCB 보드 재료는 폴리 테트라 플루오로 에틸렌입니다. (PTFE) 복합 재료, 더 큰 통합 번호를 가진 세라믹 충전 입자를 포함하는 (>50%). Rt의 높은 충전 특성 / 듀로이드 6002, RO3000 시리즈 및 RO3200 시리즈 PCB 보드 재료가 낮은 Z 축 열 확장 계수를 갖습니다. (CTE), 구멍 신뢰성을 통한 우수한 전기 도금, 그리고 평평한 CTE는 구리와 밀접하게 일치하여 좋은 크기 안정성을 달성합니다.. Rt.의 필러 / 듀로이드 6006 그리고 6010 유전 상수가 높고 회로 크기를 줄입니다.

재료의 높은 충전 용량은 또한 약의 다공성에 걸리기 쉽습니다. 5% 용량. 컴포지트의 마이크로 포어는 필러와 PTFE 사이의 인터페이스에 존재하는 것으로 보입니다., 스캐닝 전자 현미경으로 단면에서 감지 할 수는 없지만. PTFE 및 가공 된 세라믹 필러의 표면 성능이 낮기 때문입니다., 미세 기공은 높은 수분 흡수를 초래하지 않습니다. 하지만, 유기 용매 및 계면 활성제를 함유하는 수용액과 같은 낮은 표면 장력 액체는 마이크로 기초로 침투 할 수 있습니다..

PTFE 및 세라믹 필러는 대부분의 가공 화학 물질에 화학적으로 불활성이기 때문에, 액체 흡수는 미세 기공 만 채우고 이러한 PCB 보드 재료의 물리적 특성을 변경하지 않습니다.. 하지만, 플레이트가 고온에서 가공되기 전에 (예를 들어, 라미네이션, SN/PB 리플 로우 납땜, 등.), 복합 재료를 관통하는 휘발성 물질을 제거해야합니다.. 가공 화학 물질과 접촉 한 직후에 철저히 헹구어 부품을 굽을 때 비 휘발성 가용성 물질이 남지 않도록하십시오..

휘발성 제거

라미네이션 또는 리플 로우 납땜과 같은 고온 공정 전에 휘발성 물질을 제거하지 않으면 전기 발포 또는 탈선이 발생할 수 있습니다.. 고온 공정 동안 휘발성 물질과 관련된 문제를 제거하는 다음 베이킹 처리가 발견되었습니다..

베이킹을위한 기본 안내서

1. 라미네이션 전에.

라미네이션 전에, 라미네이트 할 내부 라미네이트는 진공 또는 300 질소의 Fegres. 플레이트가 고압 멸균기로 함께 눌린 경우, 베이킹 프로세스는 프레스 과정보다 우선합니다.

2. 구리의 화학적 침착 전에.

적어도 접시를 굽습니다 1 진공 청소기 또는 AT 300 구리의 화학적 침전 전 질소 F도. 다층 플레이트의 가장자리와 기계적 특성이 전기 전기 구리 도금으로 덮여 있기 때문에 베이킹의 열쇠입니다., 상업적으로 이용 가능한 나트륨 에테치 또는 플러싱으로부터 알코올로부터 흡수 된 에틸렌 글리콜 에테르는 제거하기가 어렵다..

3. 반사기 납땜하기 전에.

역류 결합 또는 열기 레벨링 전 (HASL), 보드는 적어도 구워졌습니다 2 진공 또는 질소에서 시간 300 도 f. 베이킹 후, 플럭스를 적용한 후 거주 시간은 30 초. 재 처리가 필요한 경우, 위의 베이킹 처리는 반복되어야합니다.

질소 정제 백에서 시트를 베이킹 할 때, 가방의 휘발성 물질이 제거되도록 가방의 질소 공기 흐름이 필요합니다.. 비슷하게, 진공 백을 사용할 때는 진공 파이프 라인이 백 재료에 의해 차단되지 않도록주의해야합니다.. 휘발성 물질이 가방에 남아있는 경우, 그들은 식히면 보드에 응축 될 것입니다.. 이것은 베이킹의 효과를 크게 줄입니다. 오븐이 예열되지 않은 경우, 권장 베이킹 시간은 오븐을 온도로 가져 오는 데 사용해야합니다..

유전체 오염

가공 화학 물질과의 접촉 후 이러한 PCB 보드 재료를 충분히 플러시하지 않으면 유전체 오염이 발생하거나 유전체 손실을 증가시킬 수 있습니다.. 이러한 문제는 비 휘발성 구성 요소를 함유 한 낮은 표면 에너지 용매에 대한 노출을 최소화하고 합리적인 플러싱 프로세스를 사용하여 예방할 수 있습니다.. 예를 들어, 필요한 에칭 시간보다 더 오래 에어에 접시를 담그는 것은 허용되지 않습니다.. 게다가, 에칭 직후에 플레이트를 플러시해야합니다.

유전체 오염 방지를위한 기본 지침

베이킹을위한 기본 안내서

1. 비 휘발성 성분을 함유 한 저 지표 에너지 용매에 대한 노출 최소화.

2. 비 휘발성 잔류 물을 방지하기 위해 정기적으로 헹구고 헹구십시오.

3. 유전체 표면이 표면 에너지가 낮은 수용성 용액 또는 비 휘발성 물질을 함유하는 수용성 유기 용액과 접촉하는 경우, 플레이트는 침입해야합니다 70 f 뜨거운 증류수 15 즉시 분.

4. 유전체 표면이 비 휘발성 물질을 함유하는 수질 불용성 용매와 접촉하는 경우, 판은 수용성 유기 용매에 담아야합니다 (예를 들어. 메탄올, 에탄올 또는 이소프로판올) ~을 위한 15 즉시 분, 그리고 뜨거운 증류수로 15 분

UGPCB 로고

UGPCB 로고