재료

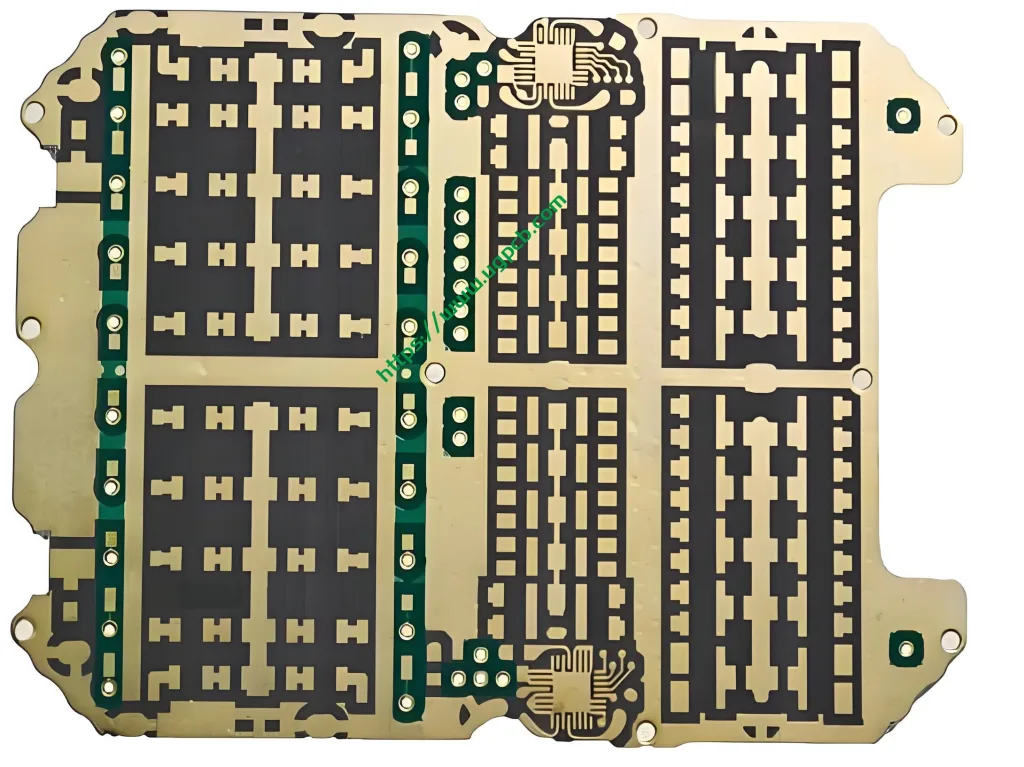

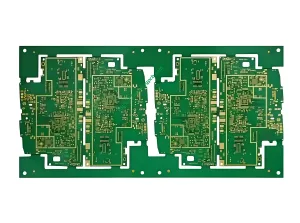

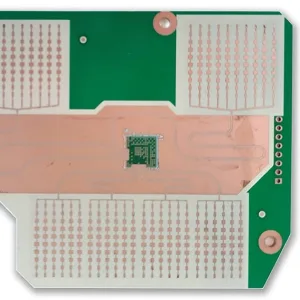

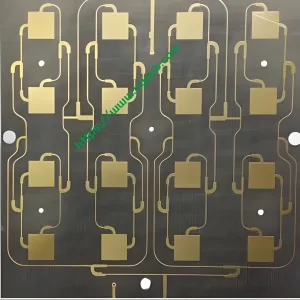

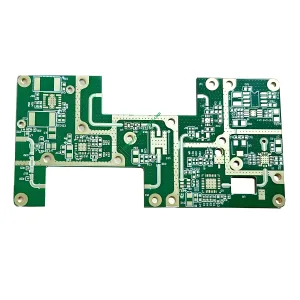

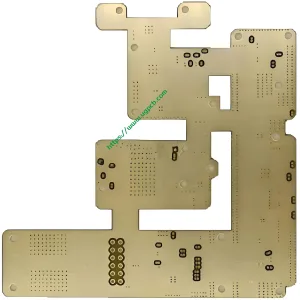

The Ro4350B Ceramic Hybrid High Frequency PCB is made from a mix of Rogers RO4350B and FR4 materials through pressing. This combination leverages the superior high-frequency performance of Rogers RO4350B ceramic substrate and the good processability of FR4, offering high performance at a cost-effective price.

성능

This product features a four-layer structure with a dielectric constant (D k) ~의 3.48, a finished thickness of 1.2mm, a copper thickness of 1OZ, a dielectric thickness of 0.508mm, and a thermal conductivity of 0.69w/m.k. 추가적으로, it boasts excellent flame retardancy, achieving the 94 다섯-0 평가, and is treated with immersion gold to enhance reliability and corrosion resistance.

생산 과정

The production process of Ro4350B Ceramic Hybrid High Frequency PCB includes material preparation, mixing and pressing, 절단, 교련, 도금, 그리고 표면 처리. 첫 번째, Rogers RO4350B and FR4 materials are mixed in a certain proportion and evenly distributed. 그 다음에, the mixed materials are pressed into sheets of the required thickness. 다음, cutting and drilling processes are performed to shape the basic form of the circuit board. 이후, plating is conducted to form conductive circuits and copper foil layers. 마지막으로, 표면 처리, such as immersion gold, is applied to enhance reliability and corrosion resistance.

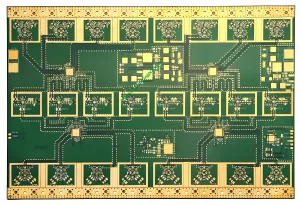

애플리케이션

Due to its excellent high-frequency performance and good processability, Ro4350B Ceramic Hybrid High Frequency PCB is widely used in communication instrument PCBs. 예를 들어, it can be used to manufacture core components of communication equipment such as high-frequency signal amplifiers, 필터, and antennas, meeting the high requirements for high-frequency performance and stability of modern communication devices.

UGPCB 로고

UGPCB 로고